- Preface

- CPwE Architecture with Industrial Data Center

- Virtualization, Thin Clients, and Industrial Data Center Description Virtualization

- Industrial Data Center Use Cases

- Industrial Data Center Verification

- Appendix A References

- Appendix B Acronyms and Initialisms

- Appendix C About the Cisco Validated Design (CVD) Program

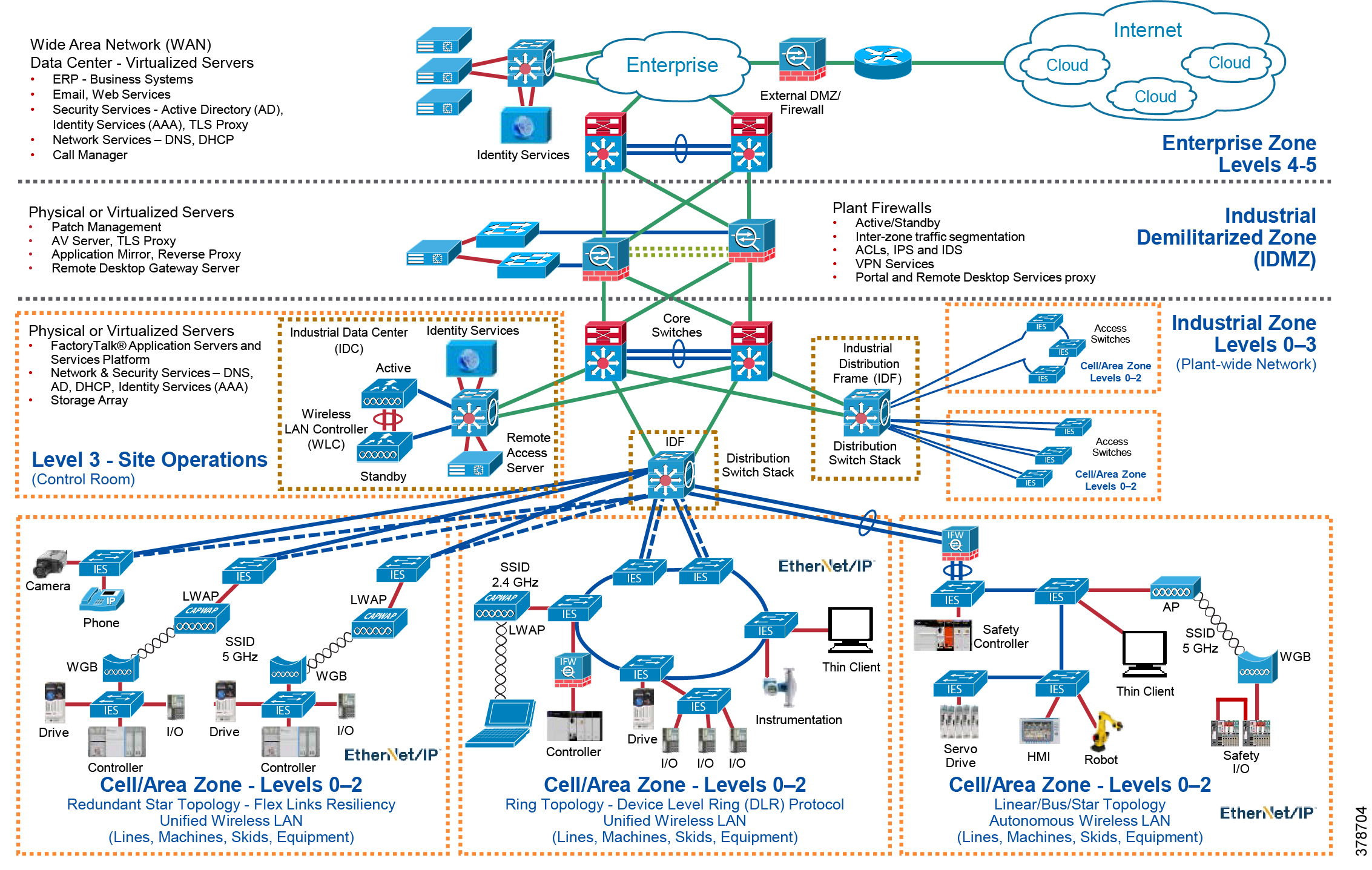

CPwE Architecture with Industrial Data Center

Business practices, corporate standards, industry standards, policies, and risk tolerance are key factors in determining the need for an IDC within a plant-wide architecture. Most network architectures supporting an Industrial Automation and Control System (IACS) application require this pivotal piece of equipment to minimize risk while maximizing overall plant uptime.

An IACS is deployed to support a variety of industry applications such as automotive, pharmaceuticals, consumer goods, pulp and paper, oil and gas, mining, and energy. IACS applications are made up of multiple control and information disciplines such as continuous process, batch, discrete, and hybrid combinations. An IACS architecture that includes an IDC can help to increase Overall Equipment Effectiveness (OEE) by reducing the impact of a failure and speed recovery from an outage, in turn lowering the Mean Time To Repair (MTTR).

The IDC functions best as part of a holistic, resilient plant-wide network architecture made up of multiple technologies, both logical and physical, deployed at different levels within the plant.

- Robust physical infrastructure

- Topologies and protocols

- Switching and routing

- Wireless LAN controllers

- Firewalls

- Network and device management

Converged Plantwide Ethernet (CPwE) is the underlying architecture that provides standard network and security services for control and information disciplines, devices, and equipment found in modern IACS applications. The CPwE architecture (Figure 1-1) provides design and implementation guidance to achieve the real-time communication, reliability, scalability, security and resiliency requirements of the IACS. The CPwE Industrial Data Center for IACS applications is brought to market through collaboration between Cisco Systems, Panduit Corp., and Rockwell Automation.

The Level 3 Site Operations Area (Figure 2-1) provides the switching, compute, and storage resources needed to efficiently operate a manufacturing facility. This area is the foundation for data collection and application hosting in the Industrial setting. This Level 3 equipment is housed in the IDC solution. Level 3 Site Operation applications range from Manufacturing Execution Systems (such as FactoryTalk® ProductionCentre®), applications like FactoryTalk and PlantPAx®, key performance indicators like OEE, lot traceability, preventive maintenance schedules, process monitoring and management, safety and security dashboards, and productivity KPIs. Continuity of service is imperative as these functions are used for daily decision making on an ever-increasing basis. Reliable and secure network support for these applications keeps production flowing and business communication running smoothly. Manufacturing network outages are readily visible and easily monetized in thousands of dollars from missed customer commitments.

Feedback

Feedback