Power Button Shut Down

The chassis runs in two modes:

-

Main power mode—Power is supplied to all components and all operating systems can run.

-

Standby power mode—Power is supplied only to the service processor and certain components. You can safely remove power cords from the chassis in this mode.

Caution |

After you shut down the chassis to standby power, electric current is still present in the chassis. To completely remove power as directed in some maintenance procedures, you must disconnect all power cords from all power supplies in the chassis. |

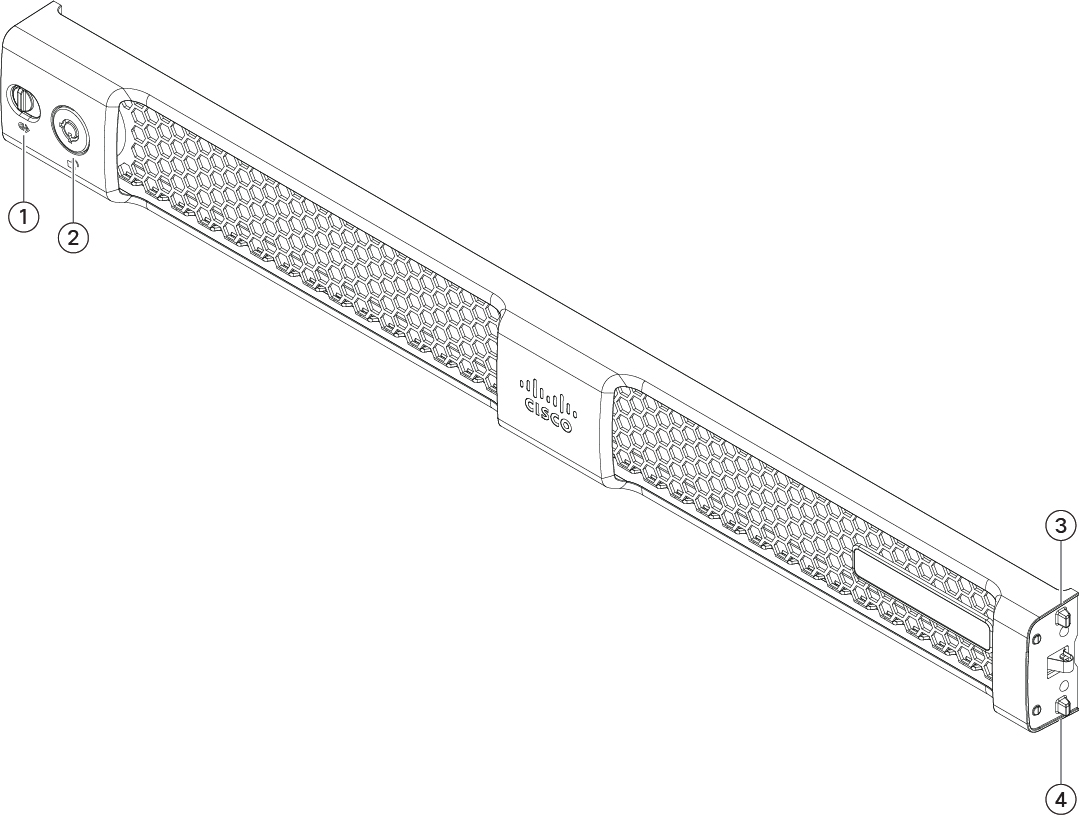

You can shut down the chassis using the front panel Power button or software management.

Procedure

|

Step 1 |

Check the Power LED:

|

||

|

Step 2 |

Perform a graceful shutdown or a hard shutdown:

|

||

|

Step 3 |

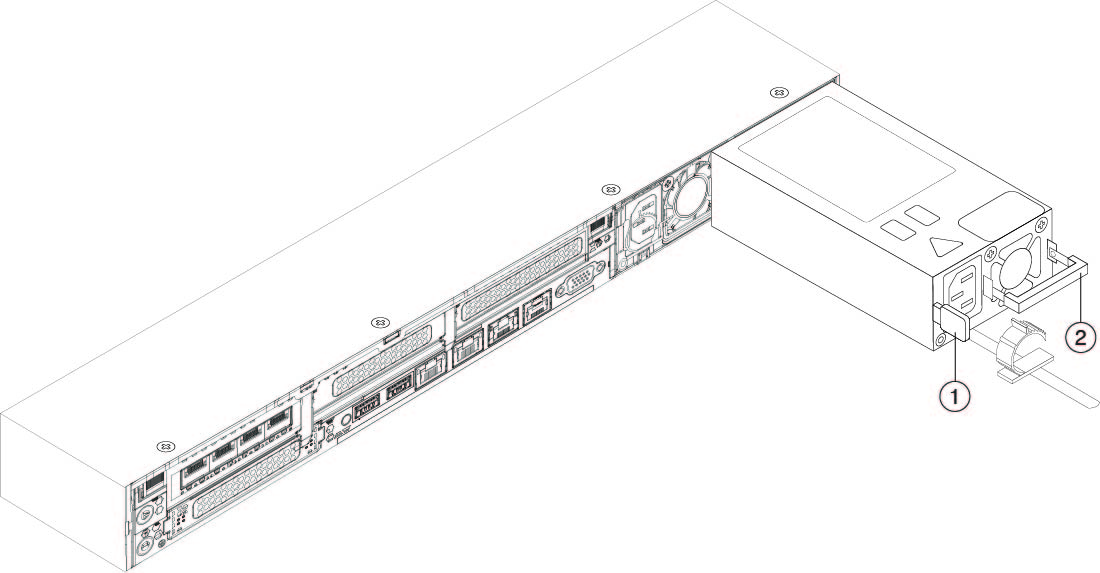

If a maintenance procedure instructs you to completely remove power from the chassis, disconnect all power cords from the power supplies. |

Feedback

Feedback