After the device is installed, you are ready to connect the DC power and alarm connections.

The device has two alarm input and one alarm output relay circuits for external alarms. The alarm input circuits are designed

to sense if the alarm input is open or closed relative to the alarm input reference pin. Each alarm input can be configured

as an open or closed contact. The alarm output relay circuit has a normally open and a normally closed contact.

Alarm signals are connected to the device through the six-pin alarm connector. Three connections are dedicated to the two

alarm input circuits: alarm input 1, alarm input 2, and a reference ground. An alarm input and the reference ground wiring

connection are required to complete a single alarm input circuit. The three remaining connections are for the alarm output

circuit: a normally open output, a normally closed output, and a common signal. An alarm output and the common wiring connection

are required to complete a single alarm output circuit.

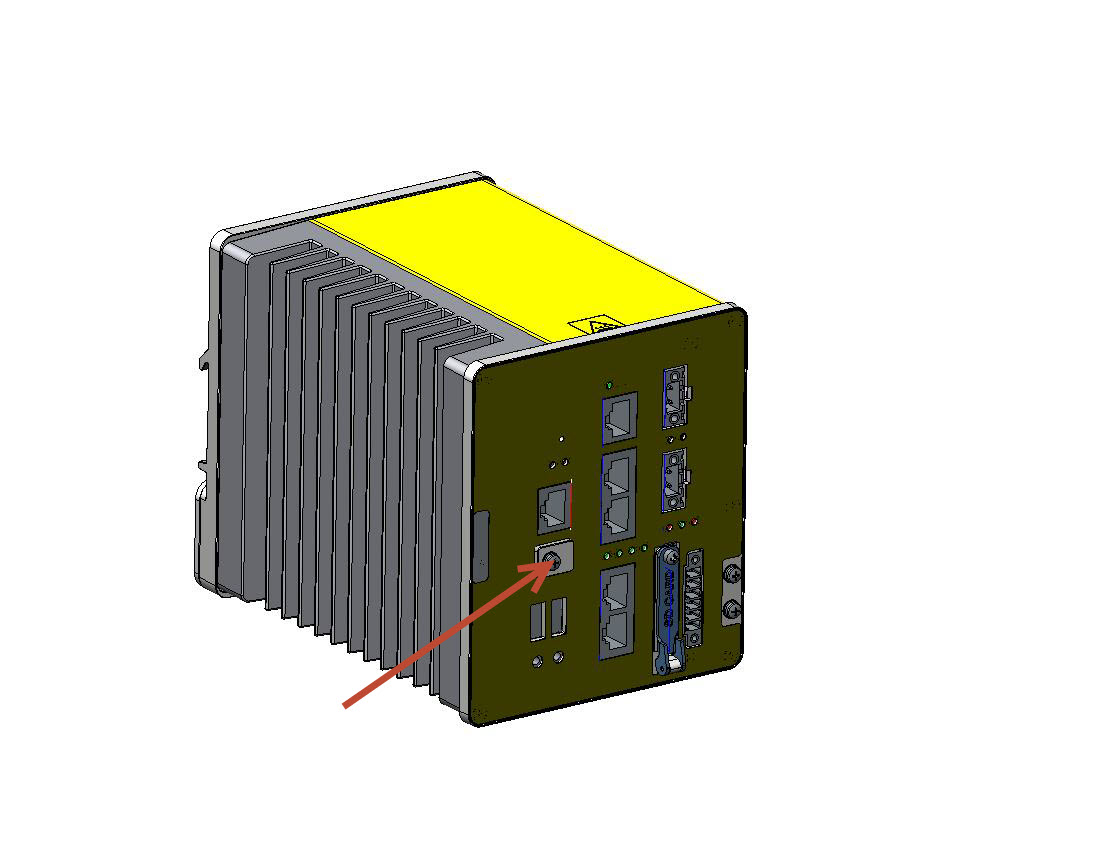

The alarm connectors are on the device panel and are detailed in the following table:

|

Pin

|

Connection

|

|

1

|

Alarm Output Normally Open (NO) connection

|

|

2 (COM)

|

Alarm Output Common connection

|

|

3

|

Alarm Output Normally Closed (NC) connection

|

|

4 (IN2)

|

Alarm Input 2

|

|

5 (REF)

|

Alarm Input Reference Ground connection

|

|

6 (IN1)

|

Alarm Input 1

|

Warning

|

Explosion Hazard—Do not connect or disconnect wiring while the field-side power is on; an electrical arc can occur. This could

cause an explosion in hazardous location installations. Be sure that power is removed or that the area is nonhazardous before

proceeding. Statement 1081

|

Caution

|

The input voltage source of the alarm output relay circuit must be an isolated source and limited to less than or equal to

24 VDC, 1.0 A or 48 VDC, 0.5 A.

|

Note

|

Wire connections to the power and alarm connectors must be UL- and CSA-rated, style 1007 or 1569 twisted-pair copper appliance

wiring material (AWM) wire (such as Belden part number 9318).

|

Feedback

Feedback