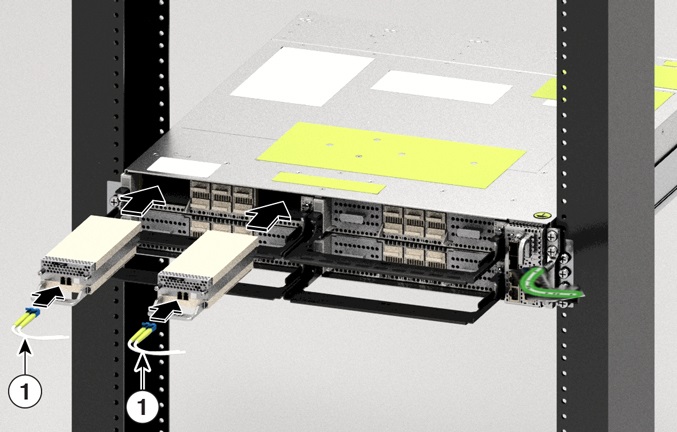

Install the Solid State Drive (SSD)

Use this procedure to install the SSD into the Cisco NCS 1014 chassis.

Procedure

|

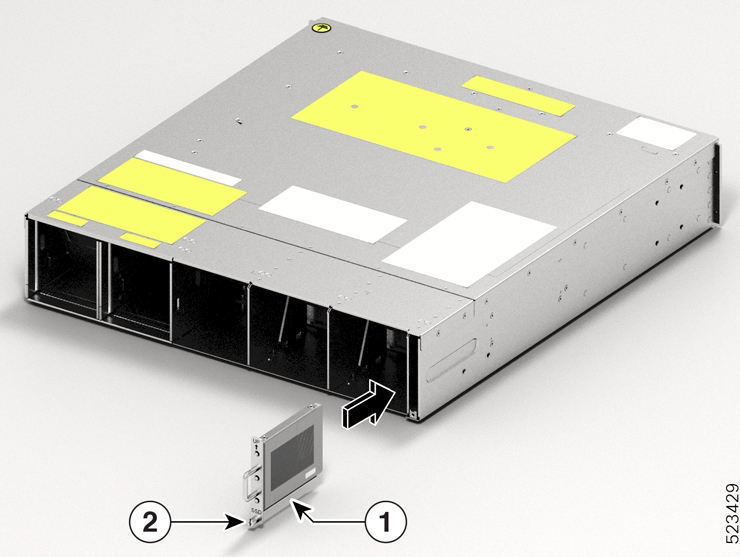

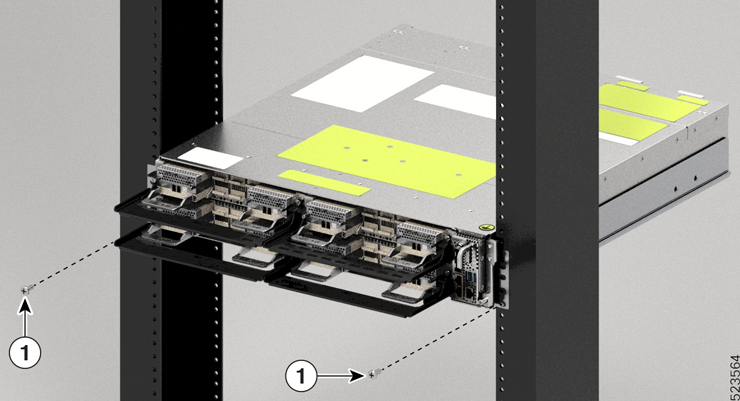

Step 1 |

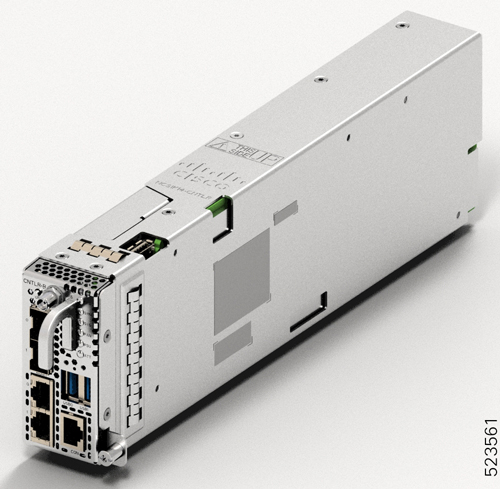

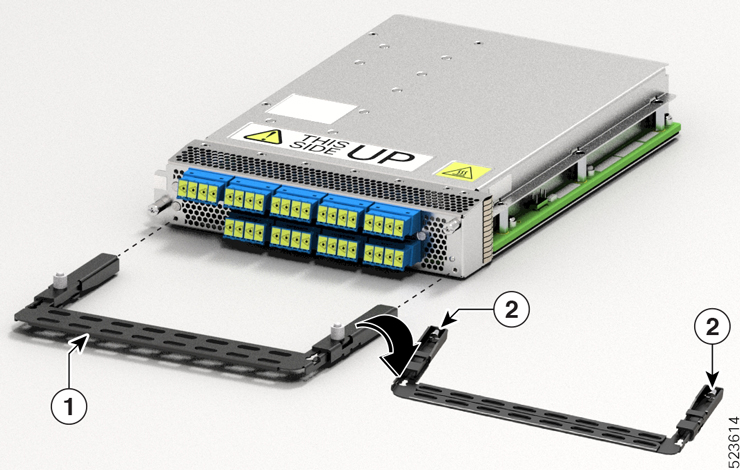

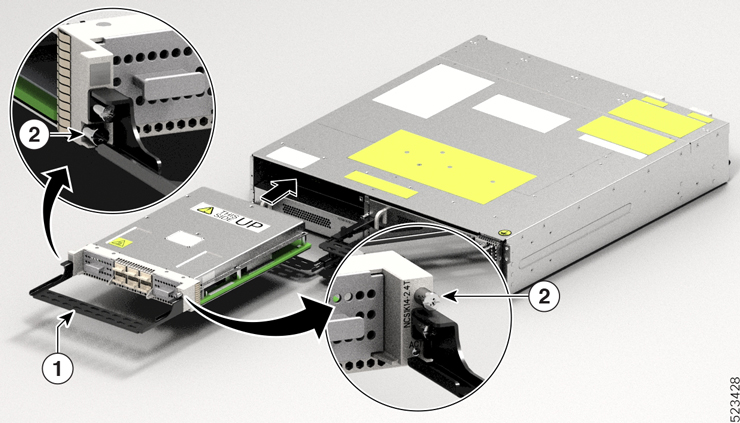

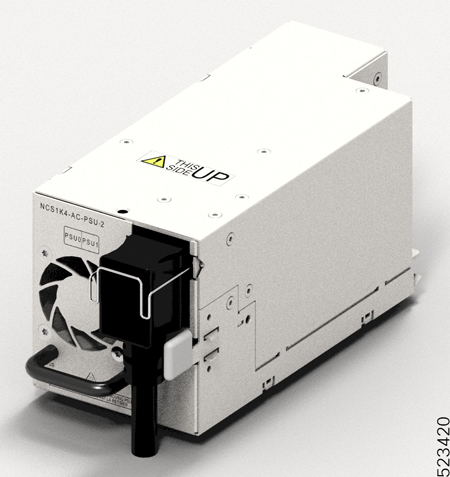

Before inserting the SSD into the slot, use the UP label to help you orient the module correctly. |

||||||

|

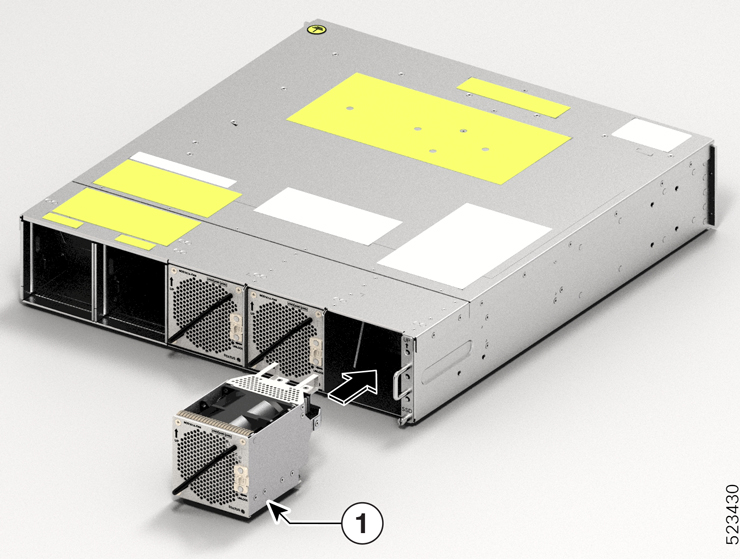

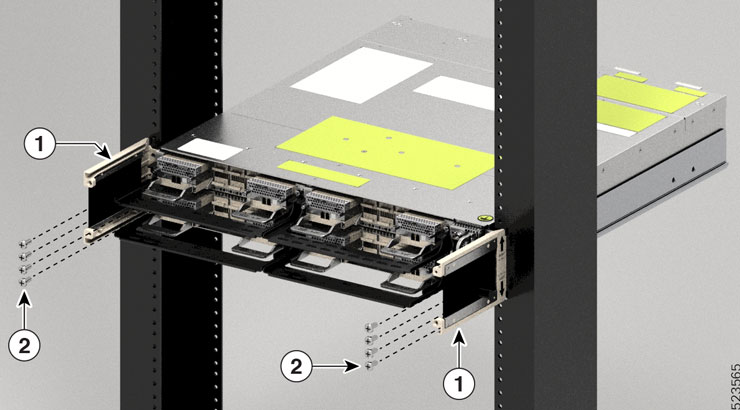

Step 2 |

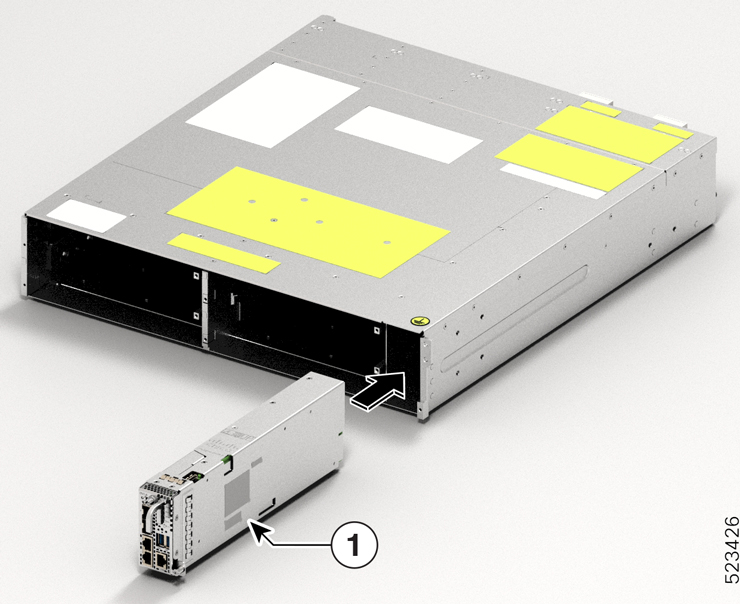

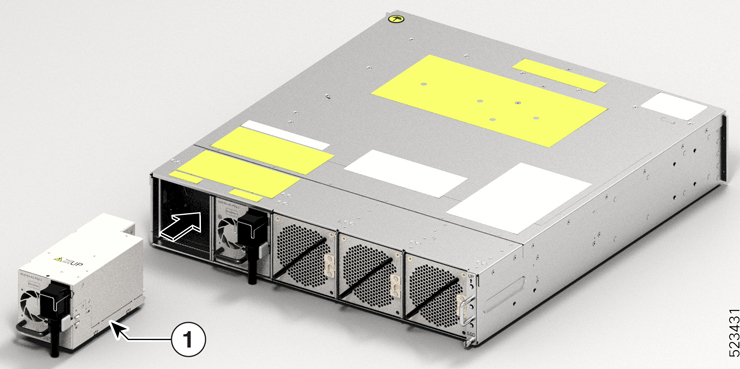

Grasp the front handle and slide the SSD into the slot.

|

||||||

|

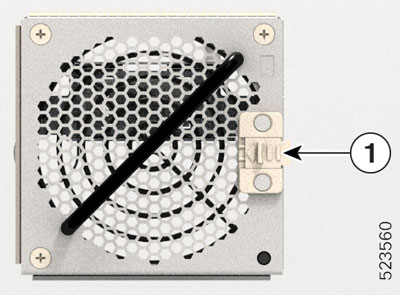

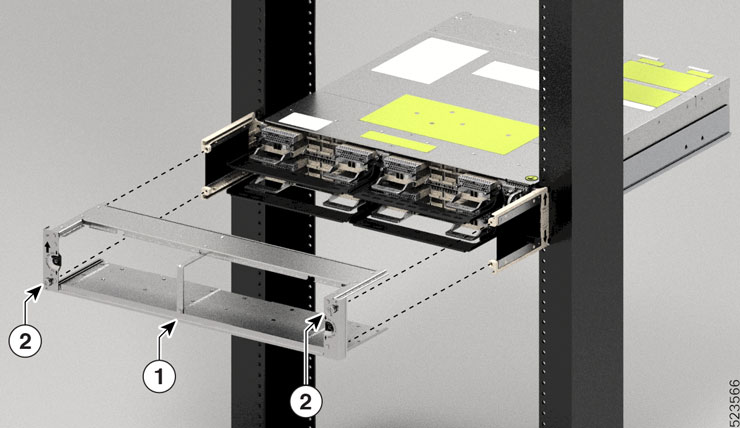

Step 3 |

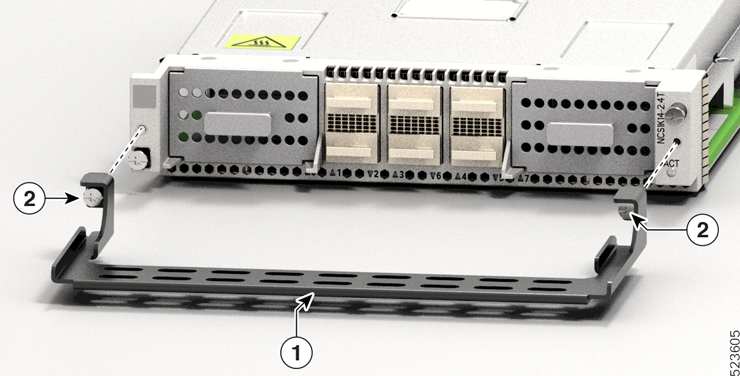

Using a T15 six lobe/slot screwdriver, tighten the lone captive screw to a torque value of 0.65 N-m (5.75 lbs-in). |

Feedback

Feedback