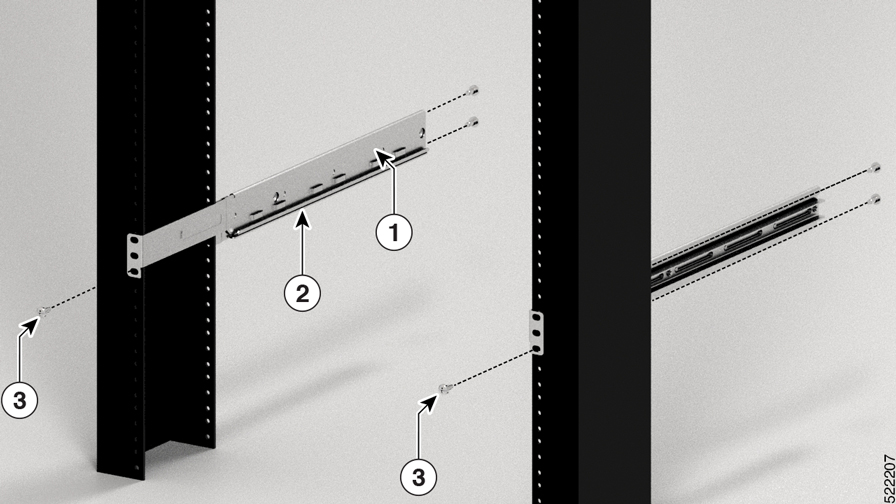

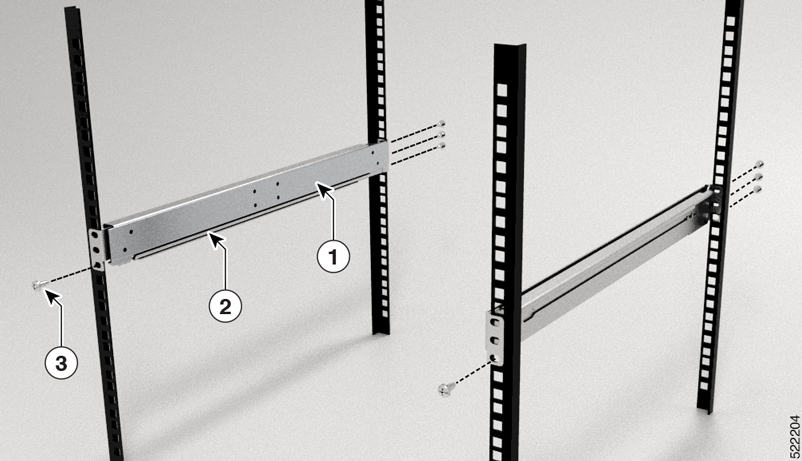

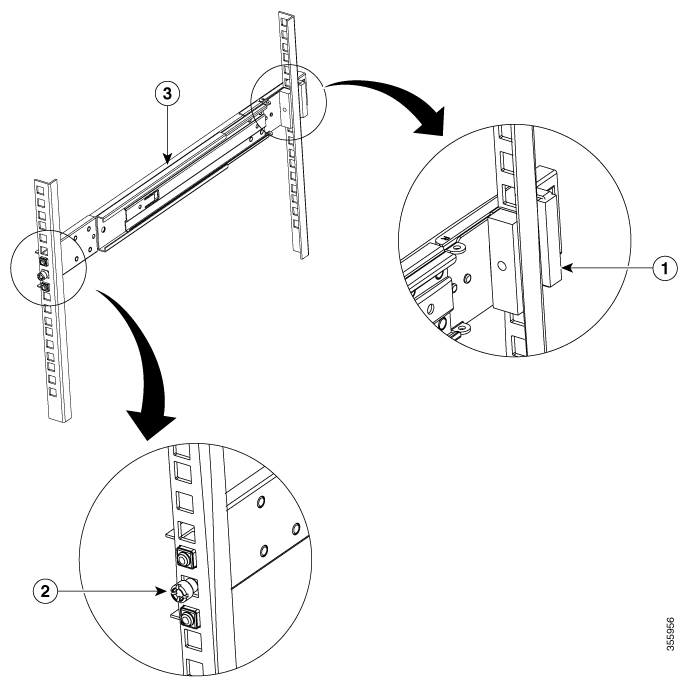

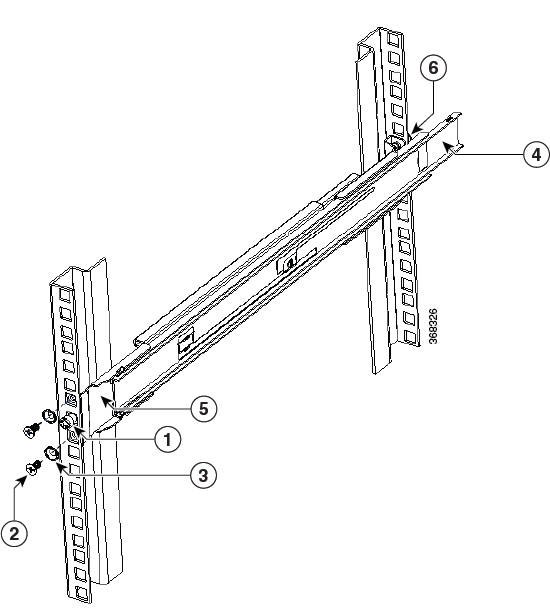

Rack Types

|

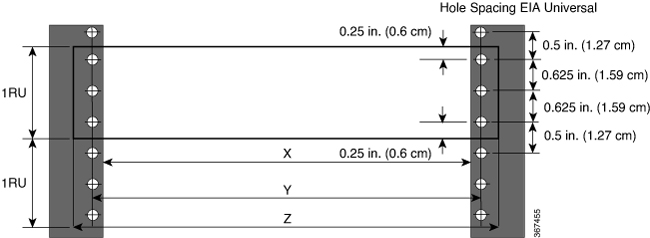

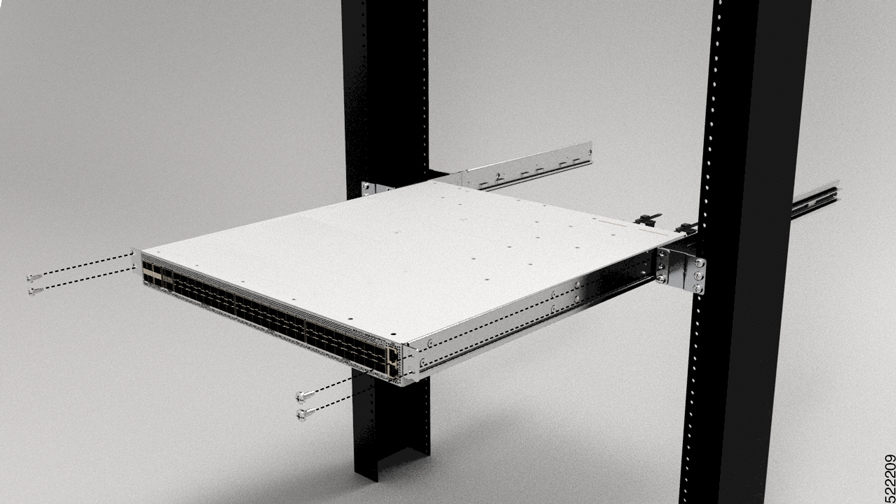

Post Type |

Rack Type |

Rack Front Opening (X) |

Rack Mounting Hole Centre-Centre (Y) |

Mounting Flange Dimension (Z) |

|---|---|---|---|---|

|

4 Post |

19 inches (48.3 centimeters) |

450.8mm (17.75”) |

465mm (18.312”) |

482.6mm (19”) |

|

2 Post |

||||

|

4 Post |

23 inches (58.4 centimeters) |

552.45mm (21.75”) |

566.7mm (22.312”) |

584.2mm (23”) |

|

2 Post |

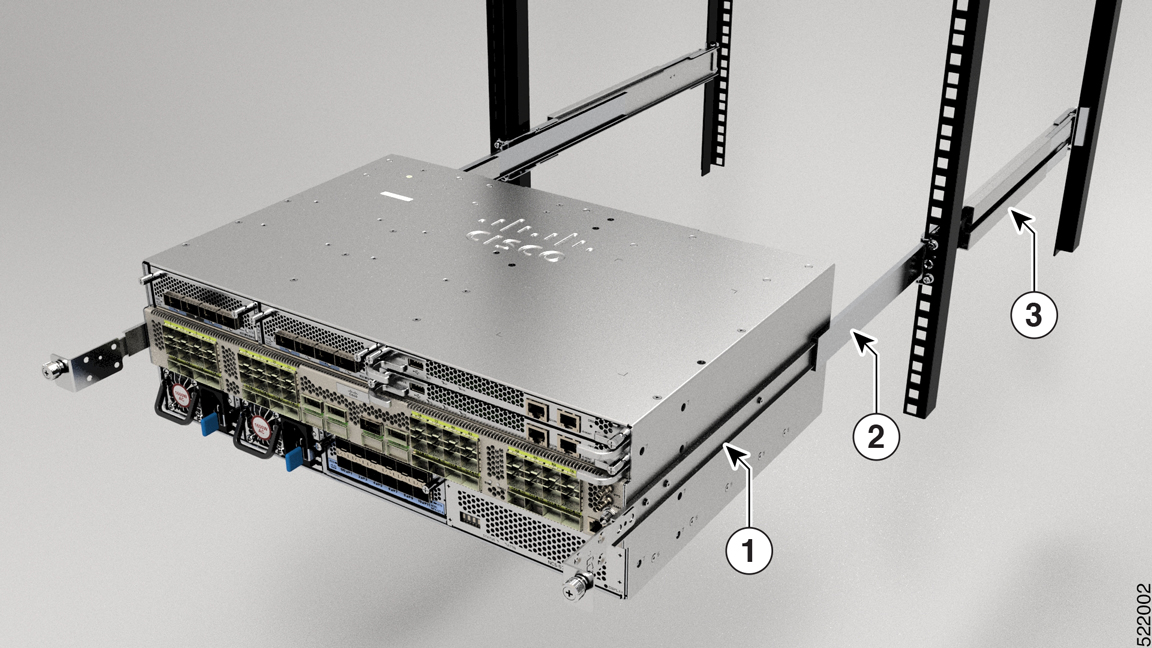

Note |

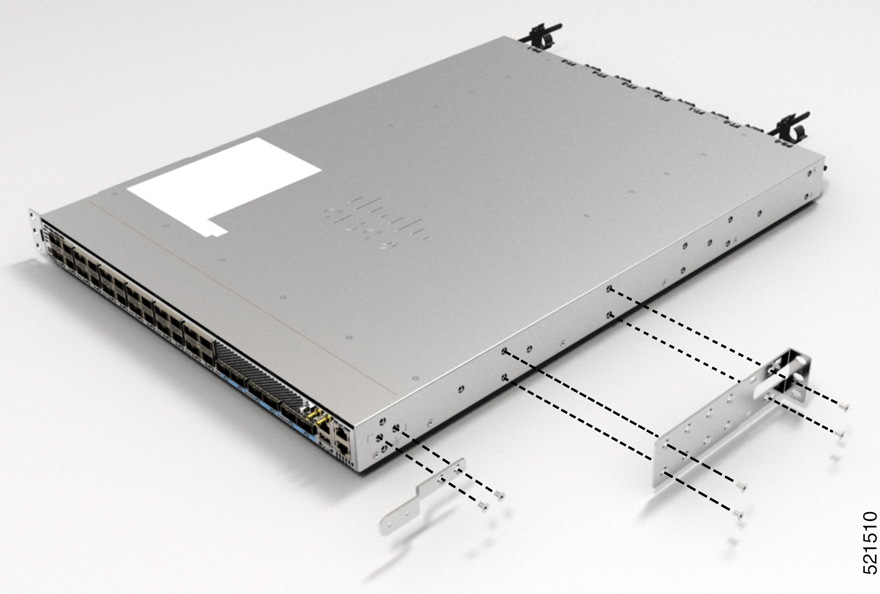

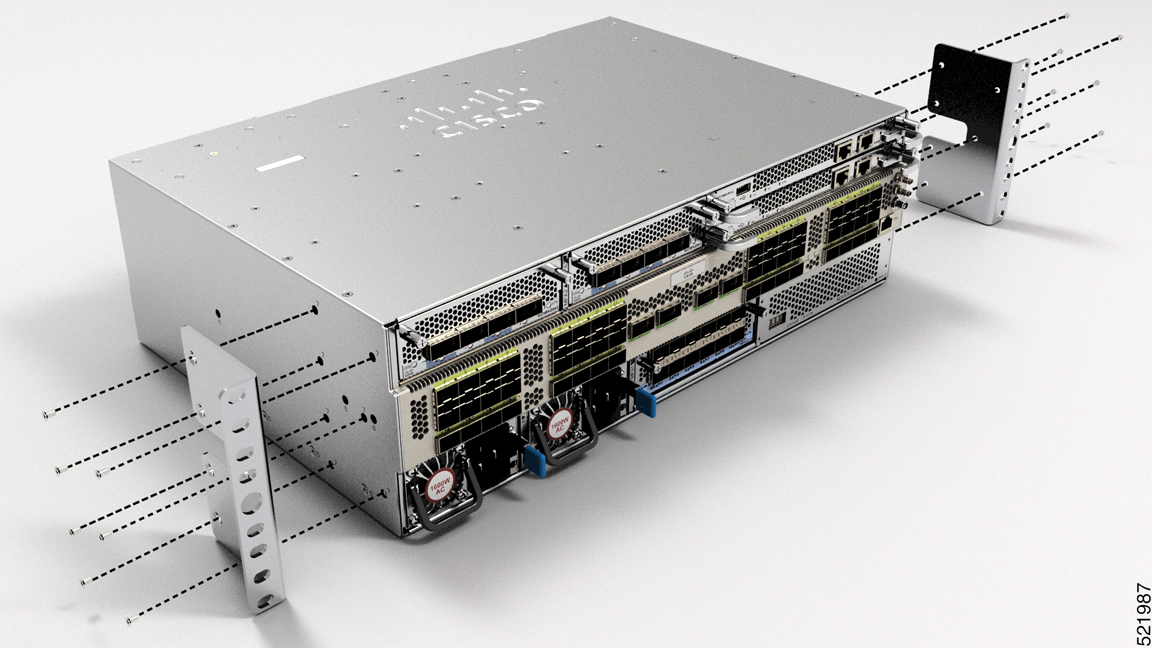

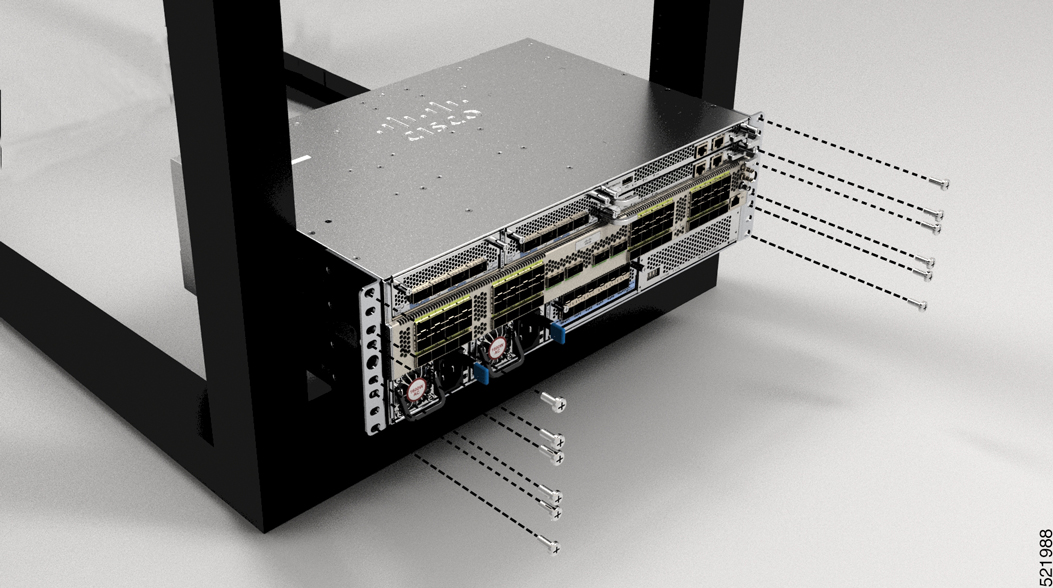

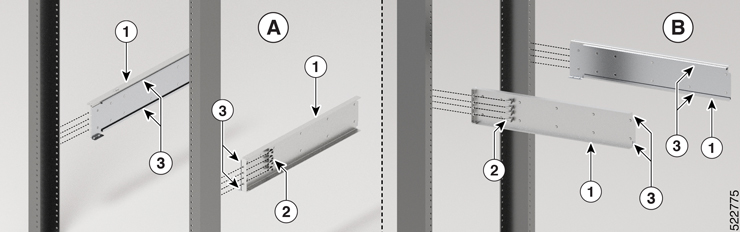

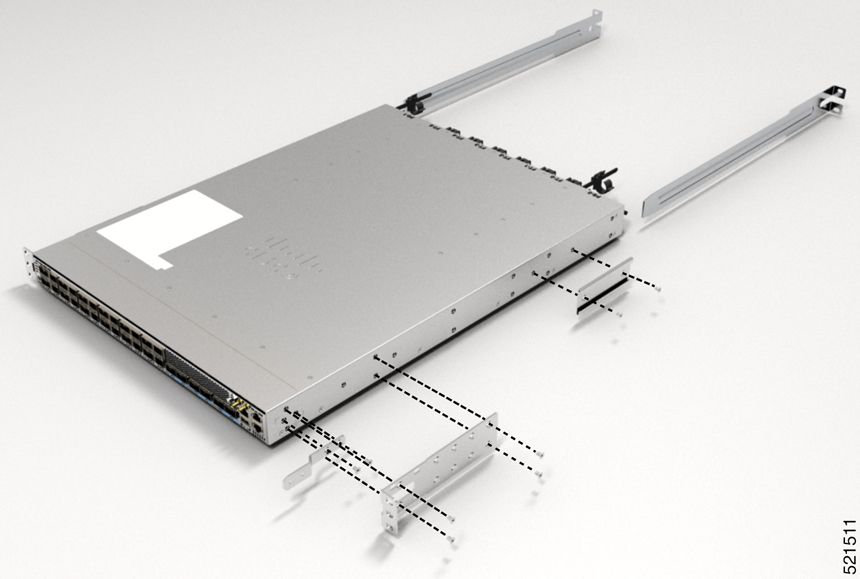

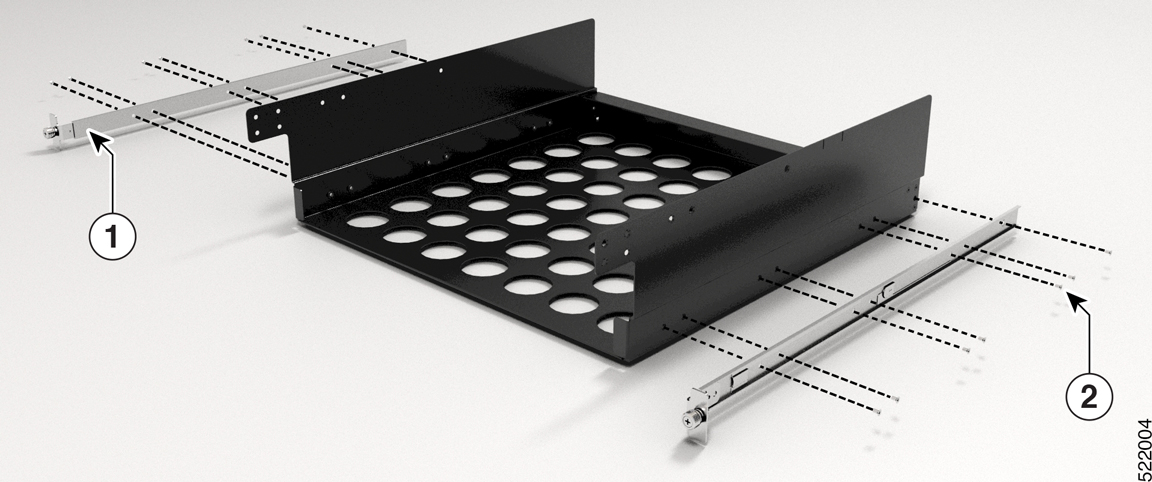

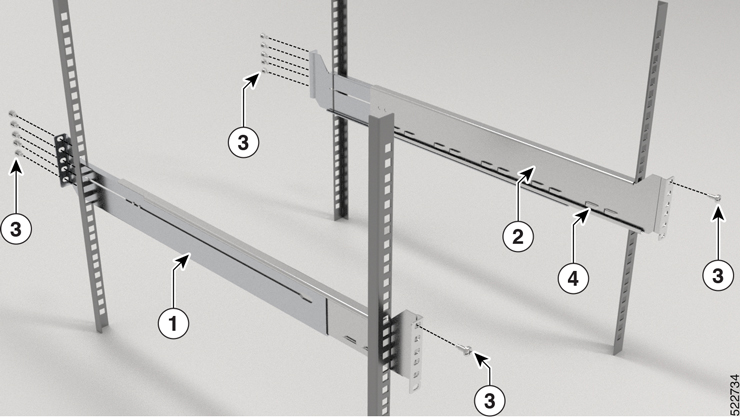

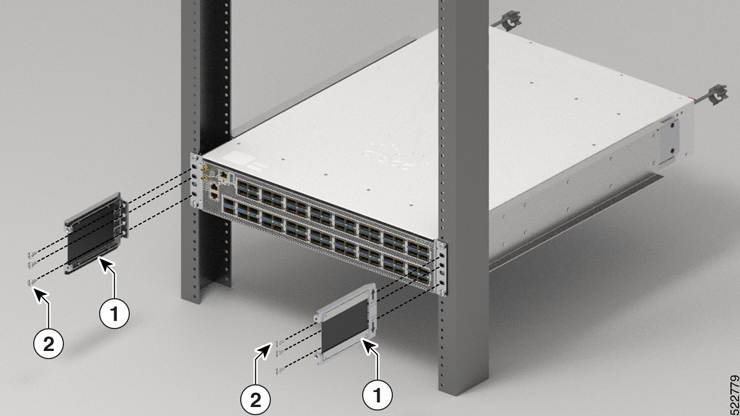

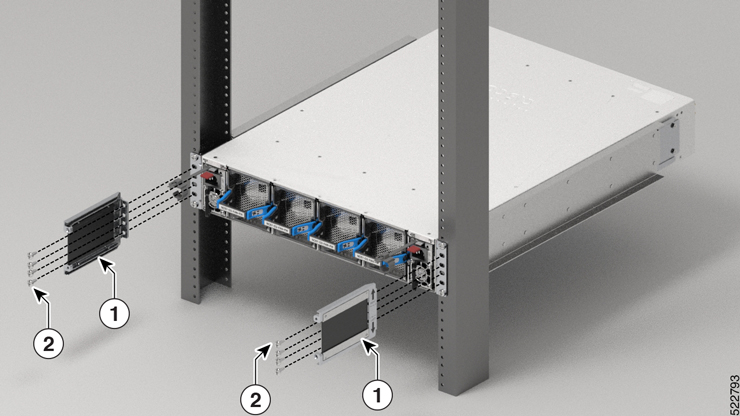

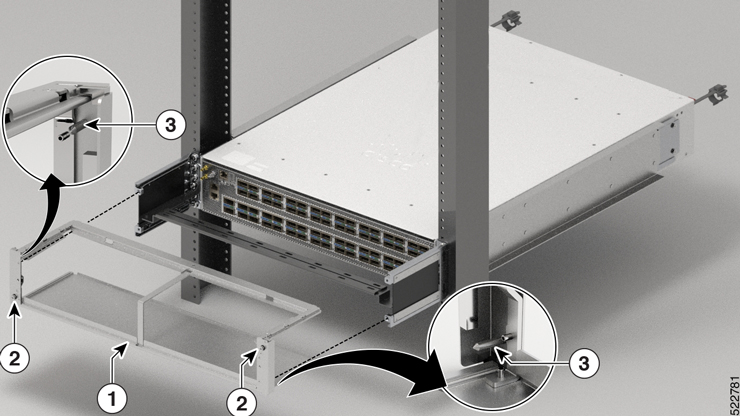

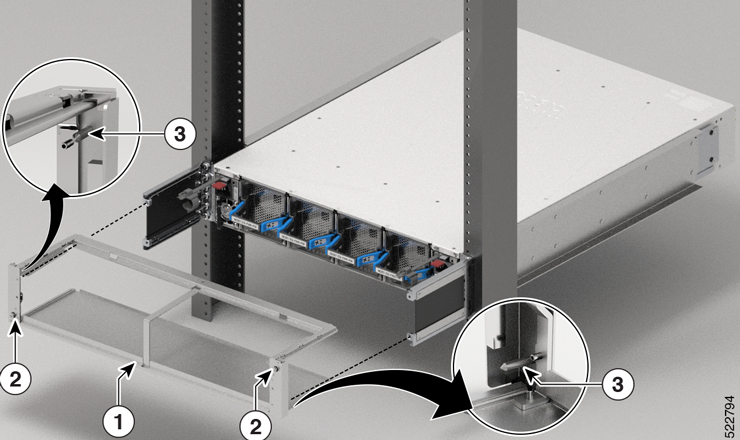

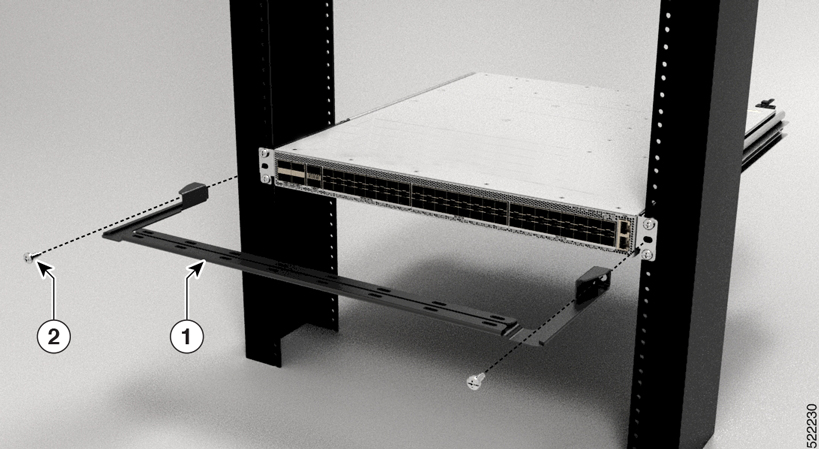

Rack mount kit contains the rack mounting brackets for 19 inch rack. To install the chassis in a 23-inch rack or an ETSI rack, you need adapter plates to accommodate the 19 inch rack mount brackets. The adapter plates for installing in a 23-inch rack or an ETSI rack are included in the accessory kit for the NCS-57C3-MOD chassis. |

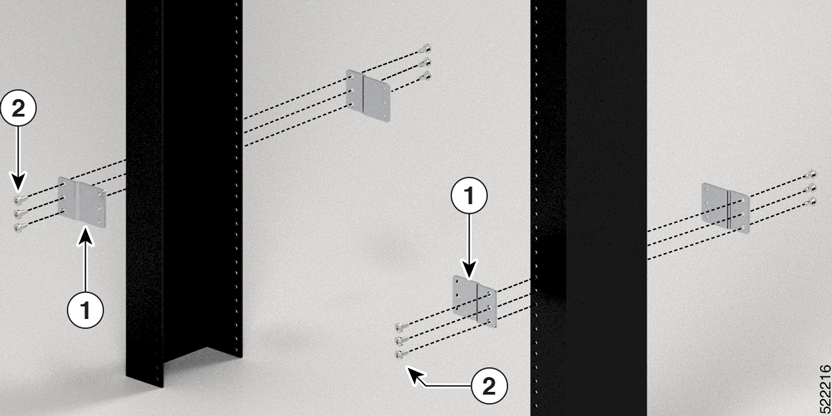

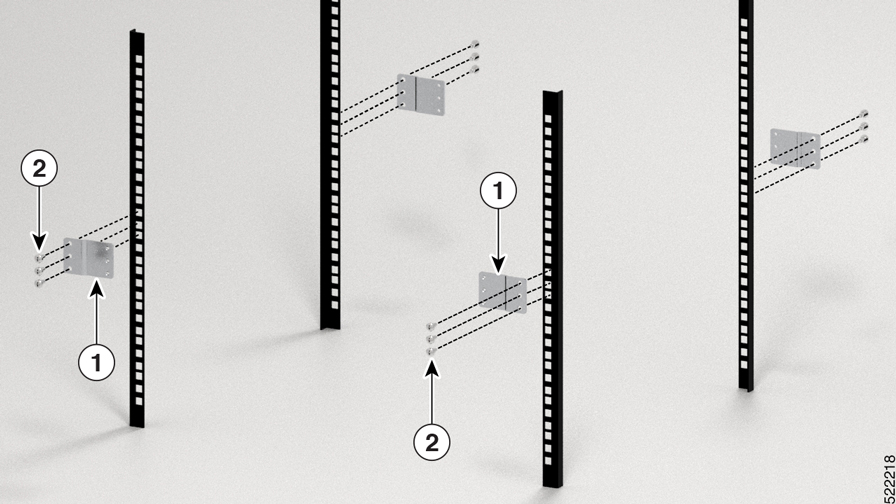

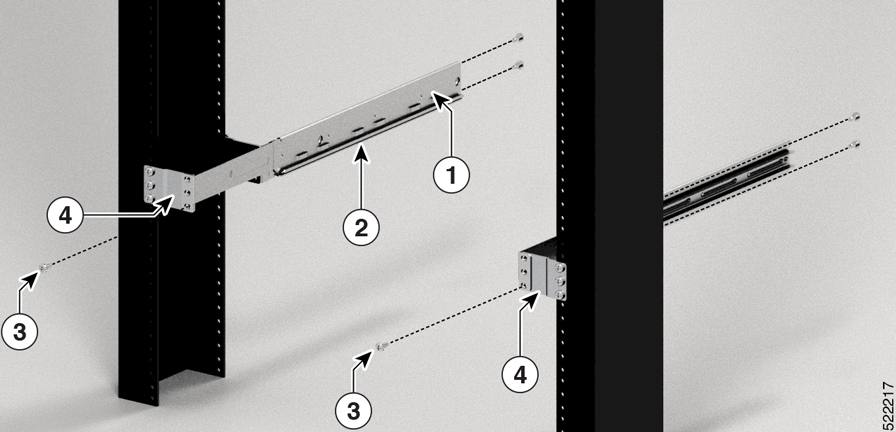

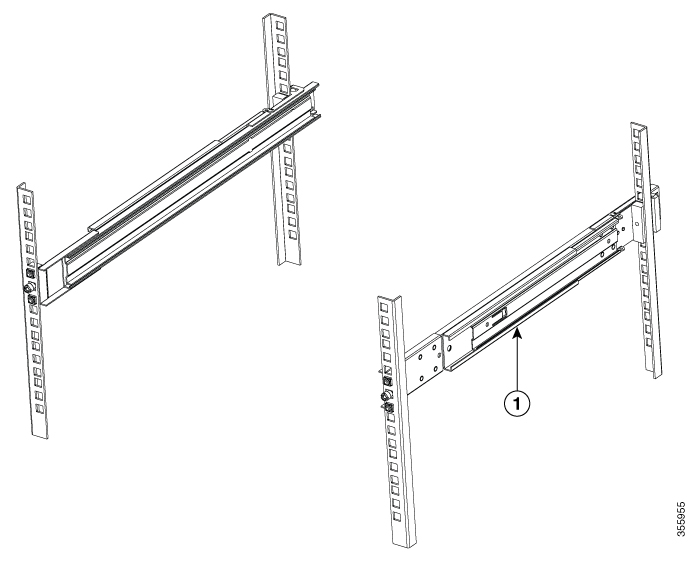

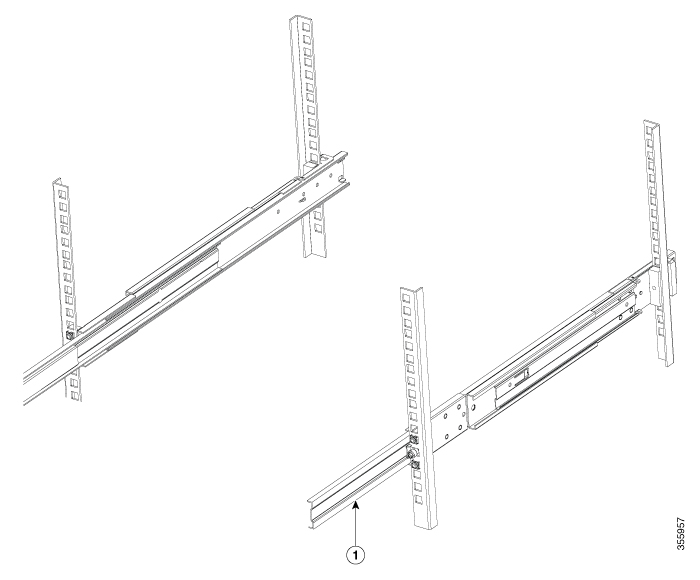

Note |

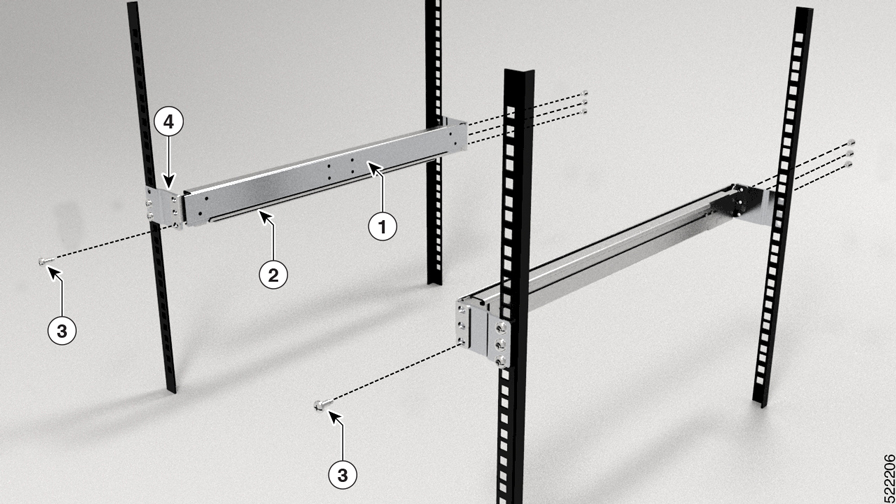

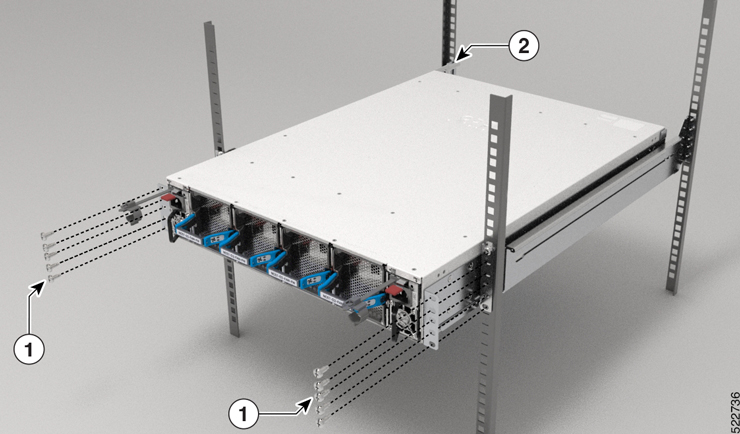

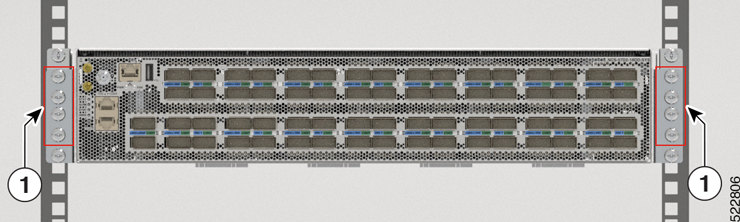

The NCS-57C1 or NCS-57D2 router can be installed either on the 19-inch rack or 23-inch rack. To install this router on the 23-inch rack, you must mount the extension brackets on the 23-inch rack post. |

Feedback

Feedback