Distribution Automation—Secondary Substation Implementation Guide

This Distribution Automation - Secondary Substation Implementation Guide provides a comprehensive explanation of the Cisco Smart Grid Field Area Network solution implementation for Secondary Substation monitoring and Distribution Automation use cases such as Fault Location, Isolation, and Service Restoration (FLISR) and Volt/VAR.

This document includes implementation information about the solution’s architecture, possible deployment models, and guidelines for deployment. It also recommends best practices and potential issues when deploying the reference architecture.

Navigator

The following table describes the content of the chapters in this document.

Chapter 1, Introduction |

|

Chapter 2, Solution Network Topology and Addressing |

Discusses the Distribution Automation secondary substation solution network topology and various IP addressing schemes used in the solution implementation. |

Chapter 3, IoT Gateway Onboarding and Management |

Includes gateway onboarding, staging, and zero touch deployment (ZTD) implementation and use case-specific template implementation. |

Chapter 4, ICT Enablement for SCADA Use Case Validation |

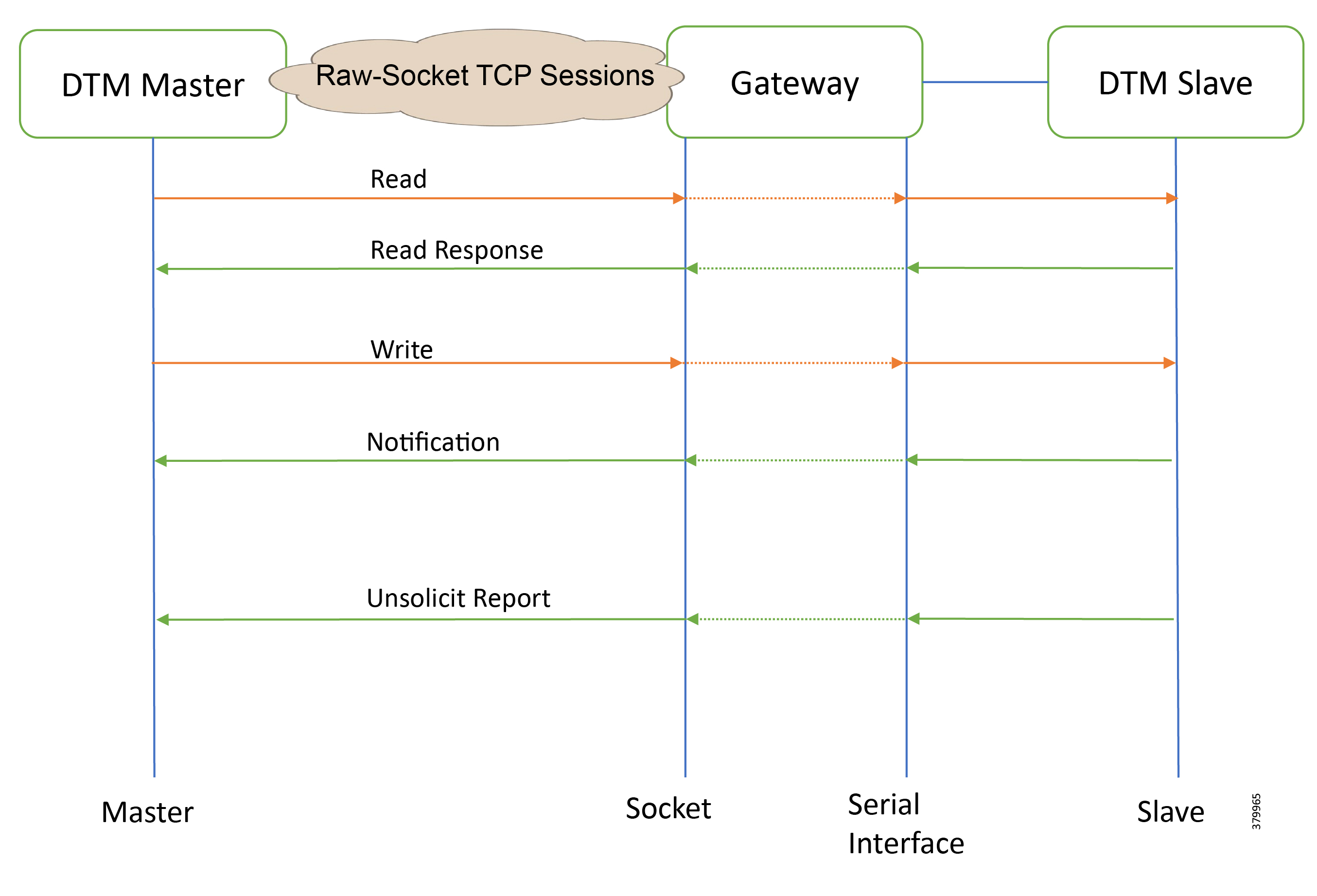

Explains the ICT implementation like routing, raw socket, and protocol translation, which are key for application traffic flow. |

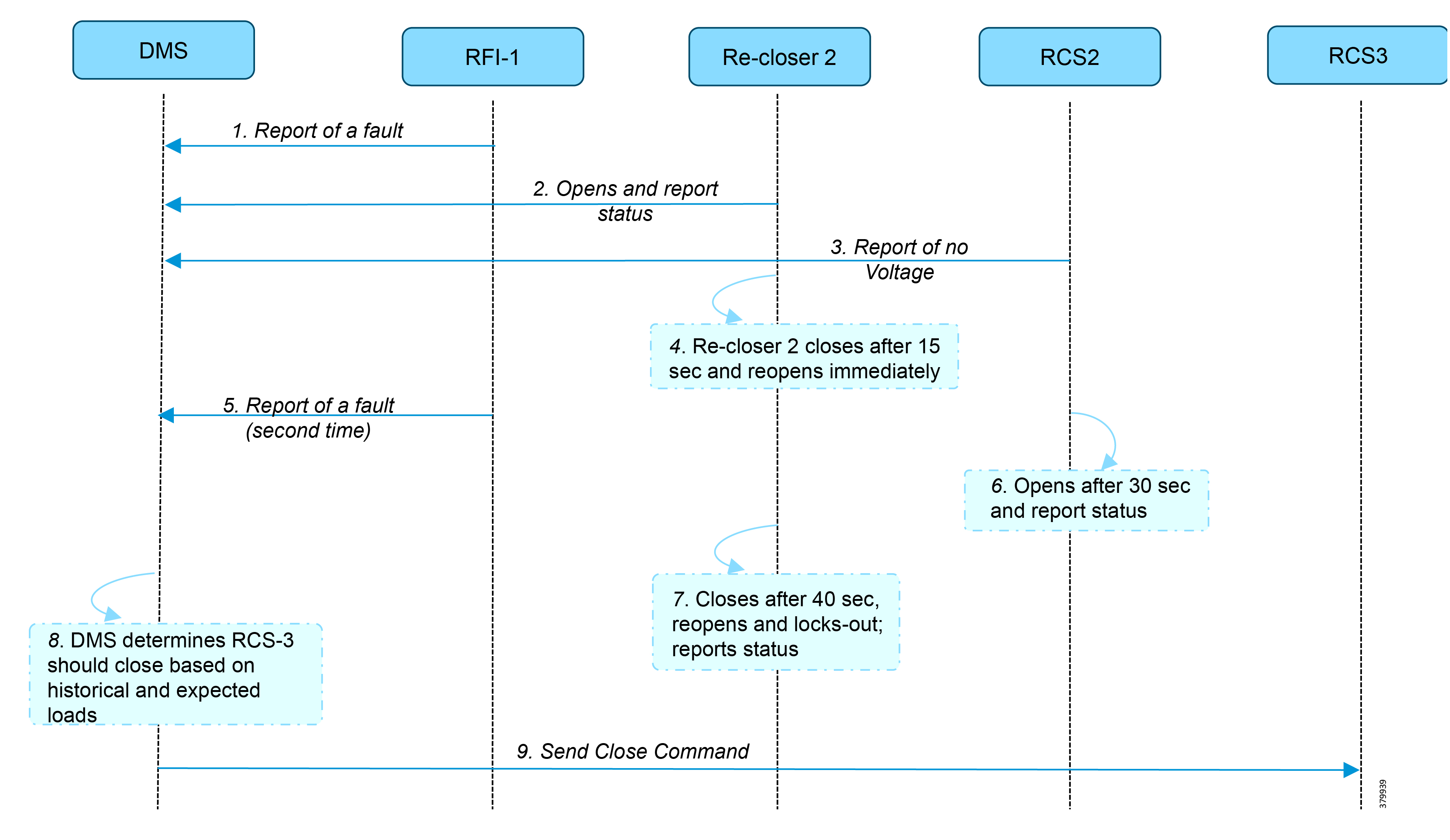

Chapter 5, End-to-End Application Use Case Scenarios |

Explains the implementation details of the fault location isolation and service restoration, Volt/VAR, and substation monitoring use cases. |

Chapter 6, High Availability at Various Layers |

Explains the implementation details of high availability aspects of this solution. |

Chapter 7, IP Services |

Explains the implementation details of various IP services like Network Address Translation, and Quality of Service. |

Captures the “Router Bootstrap Configuration” profiles for FND, for various deployment methods of Cisco IoT Gateways (with/without NAT, IPv4/IPv6). |

|

Captures the FND Tunnel Provisioning group content, as well as the FND Device Configuration group content, to facilitate ZTD of Cisco IoT Gateways. |

|

FlexVPN Configurations required for secure Tunnel provisioning. |

|

Captures the FND device configuration group's profile/content, for enablement of IP/Serial SCADA traffic on IR1101 and IR807. |

|

Captures the supplementary file details used during validation of End-to-End Application use case scenarios. |

Audience

The audience for this guide comprises, but is not limited to, system architects, network/compute/systems engineers, field consultants, Cisco Advanced Services specialists, and customers.

Readers should be familiar with networking protocols, Network Address Translation, Supervisory Control and Data Acquisition (SCADA) protocols, and have been exposed to Field Area Networks.

Introduction

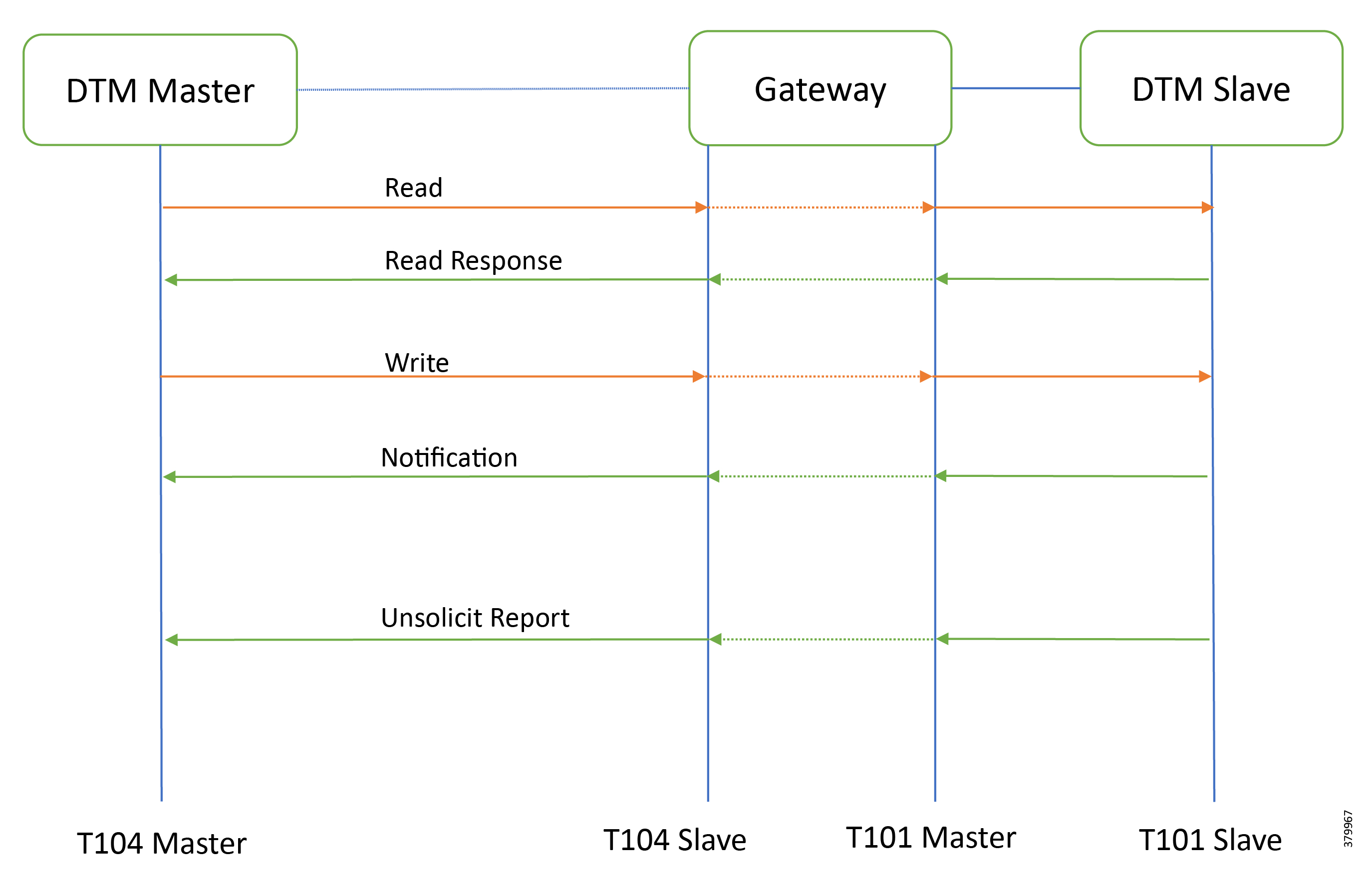

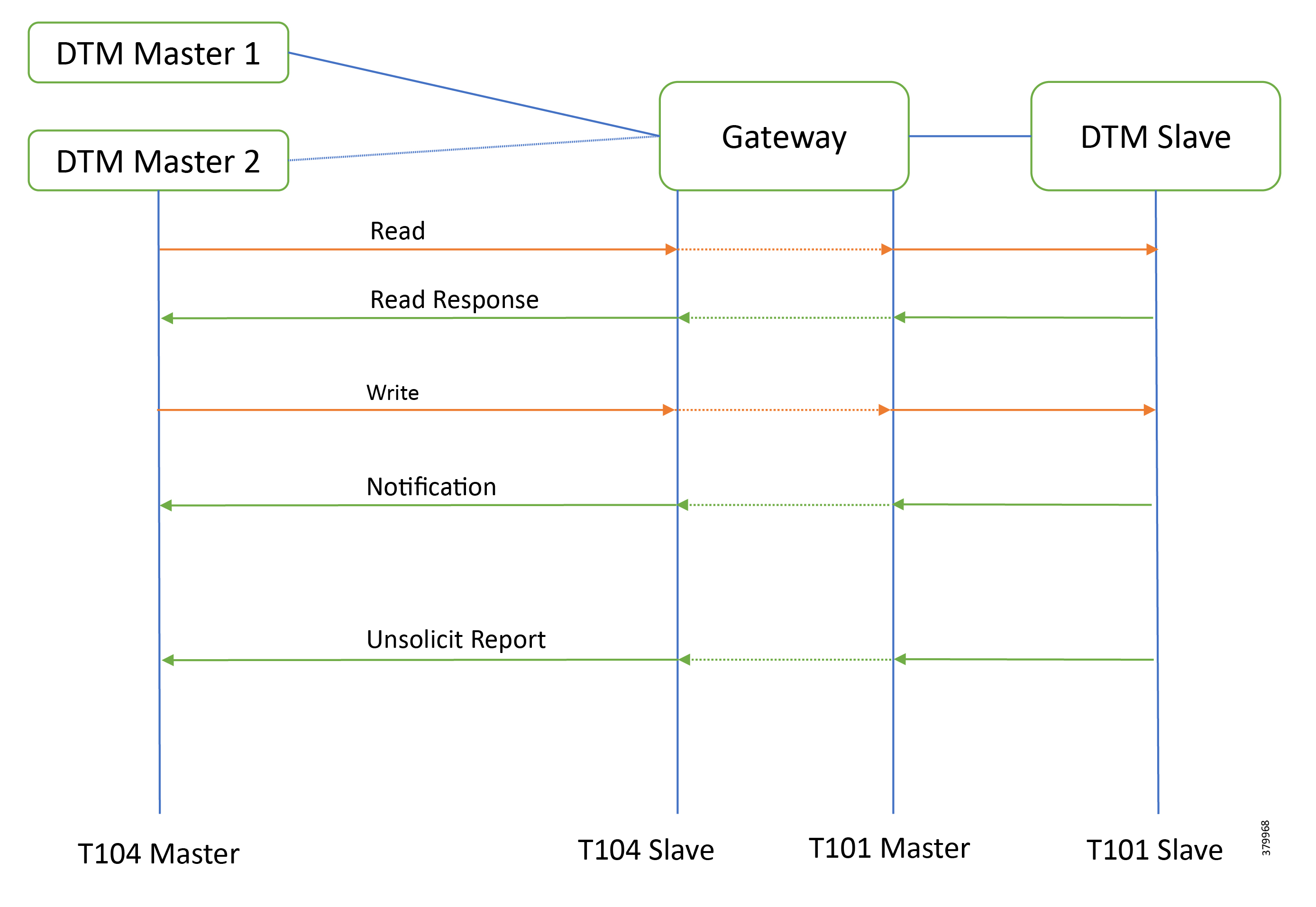

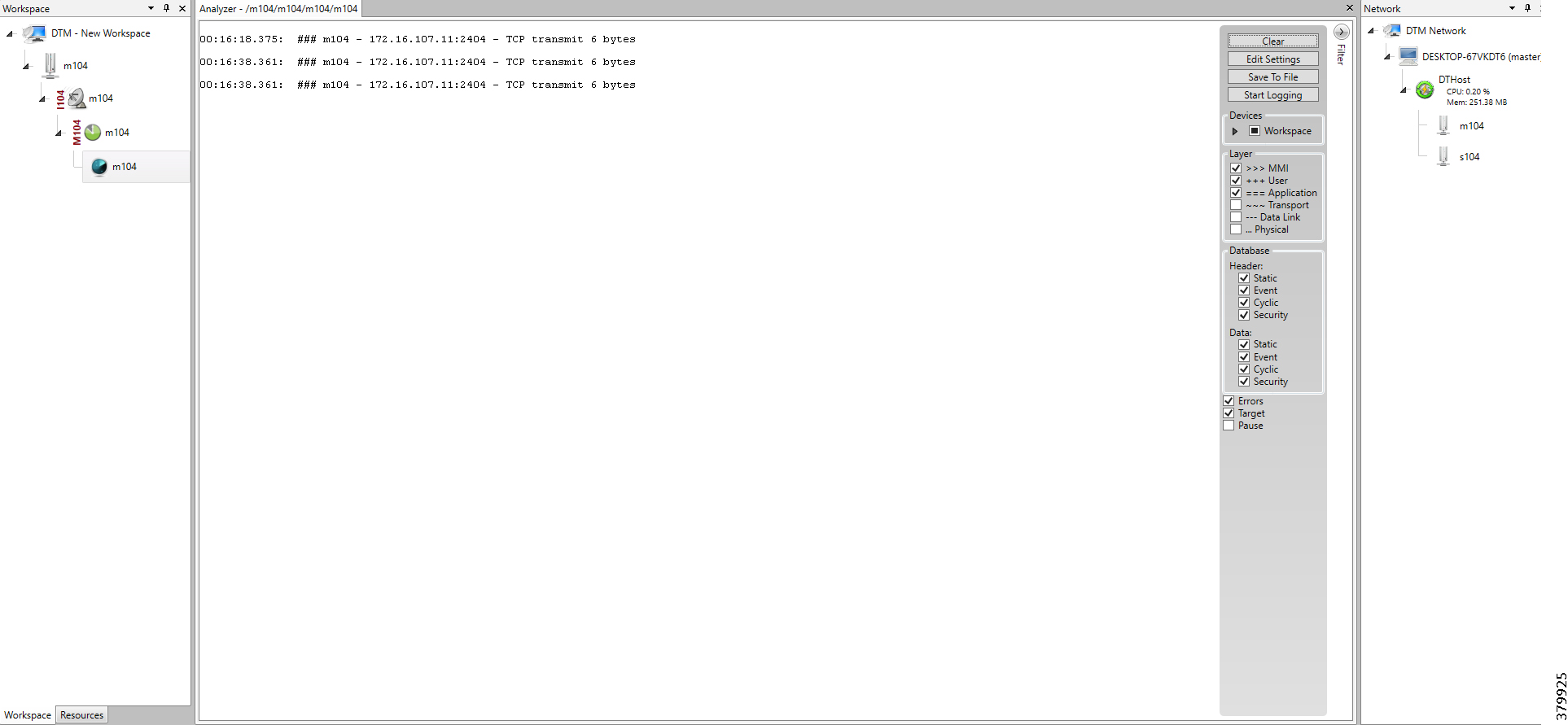

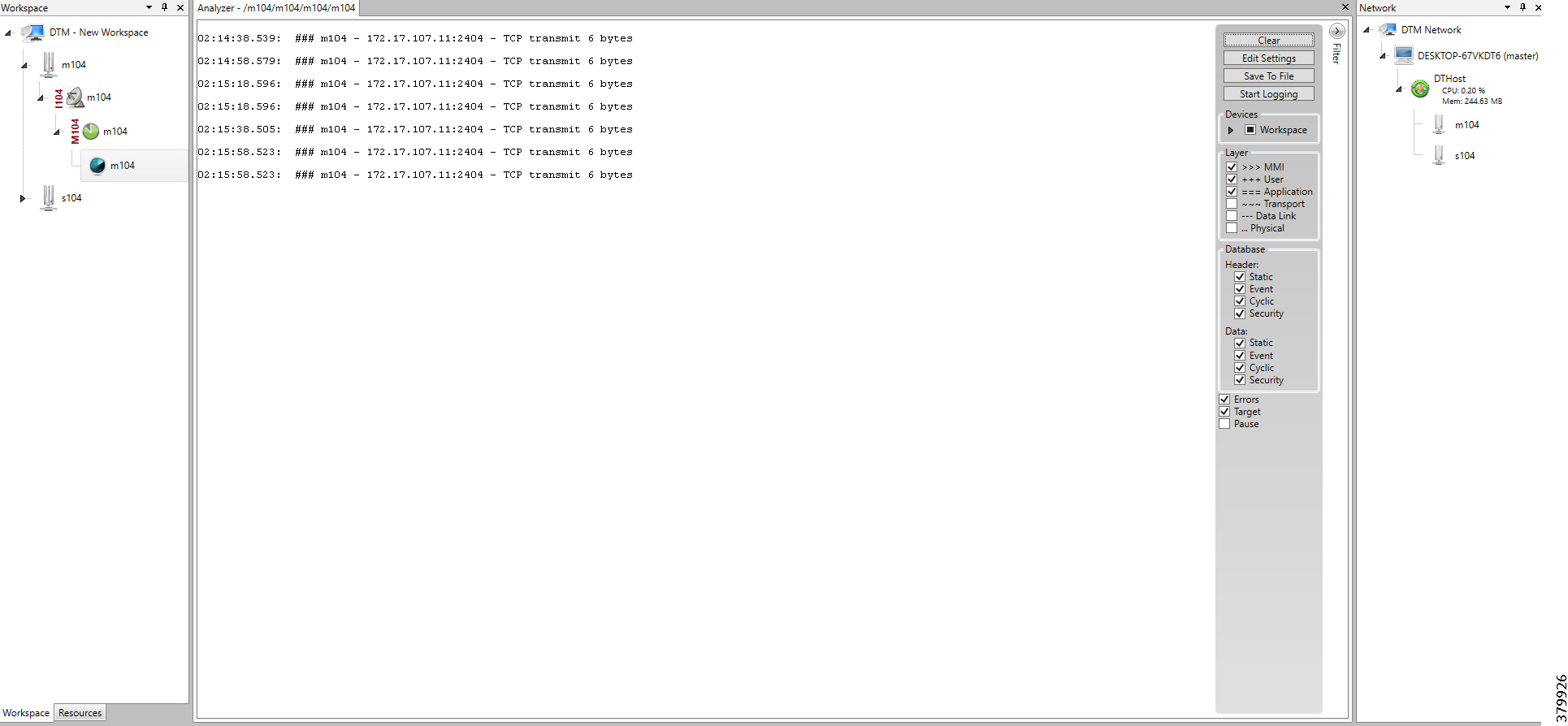

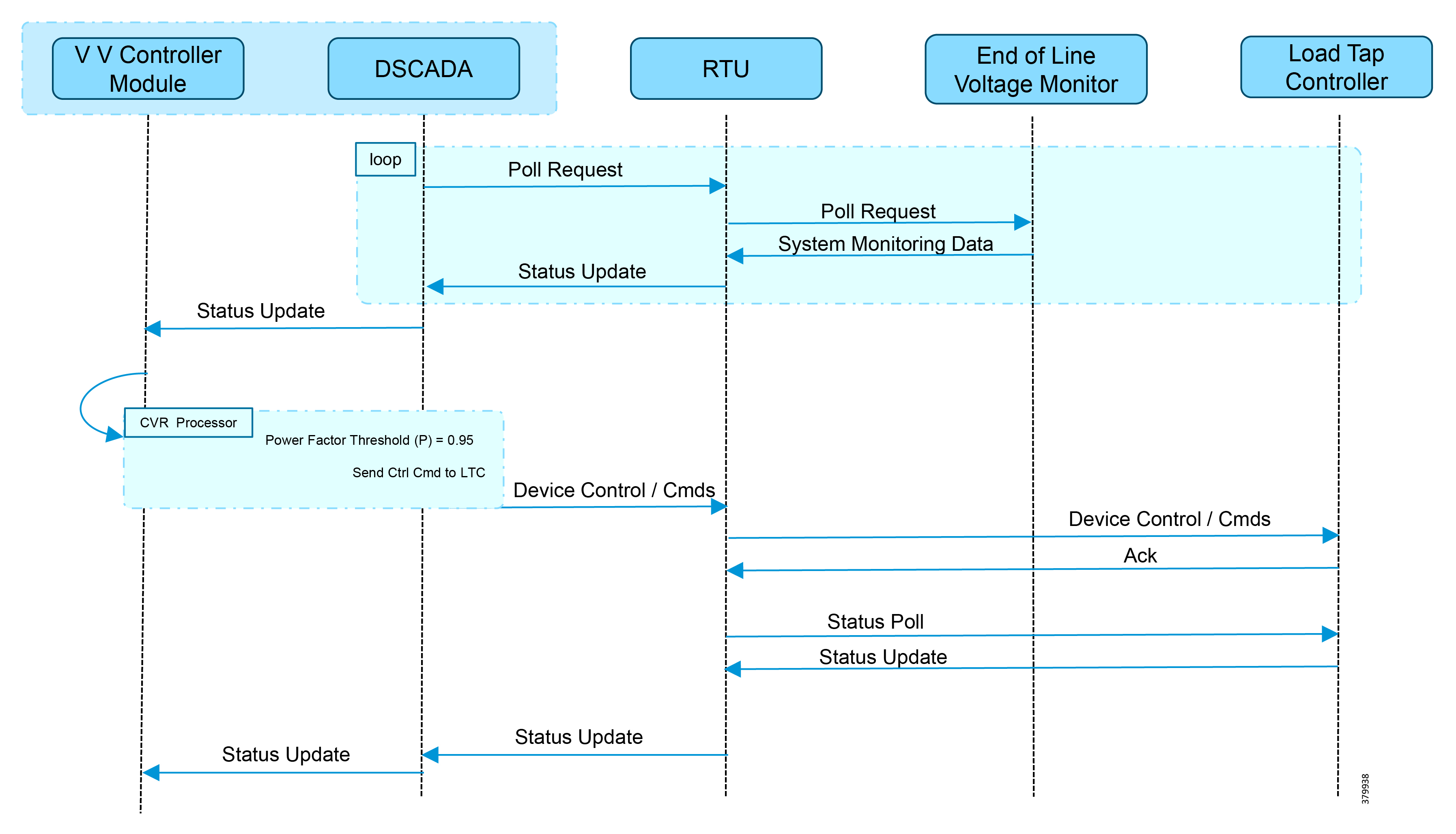

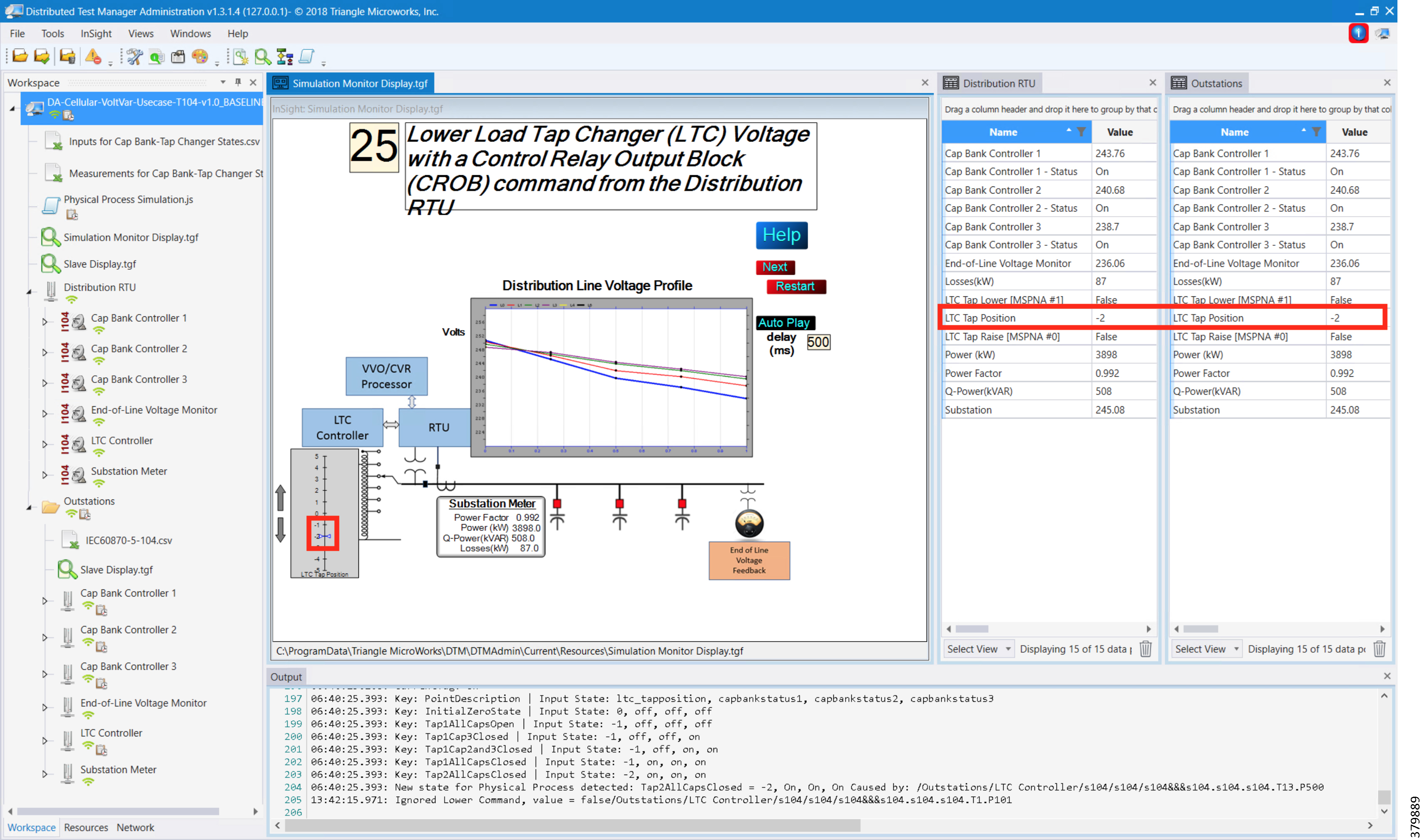

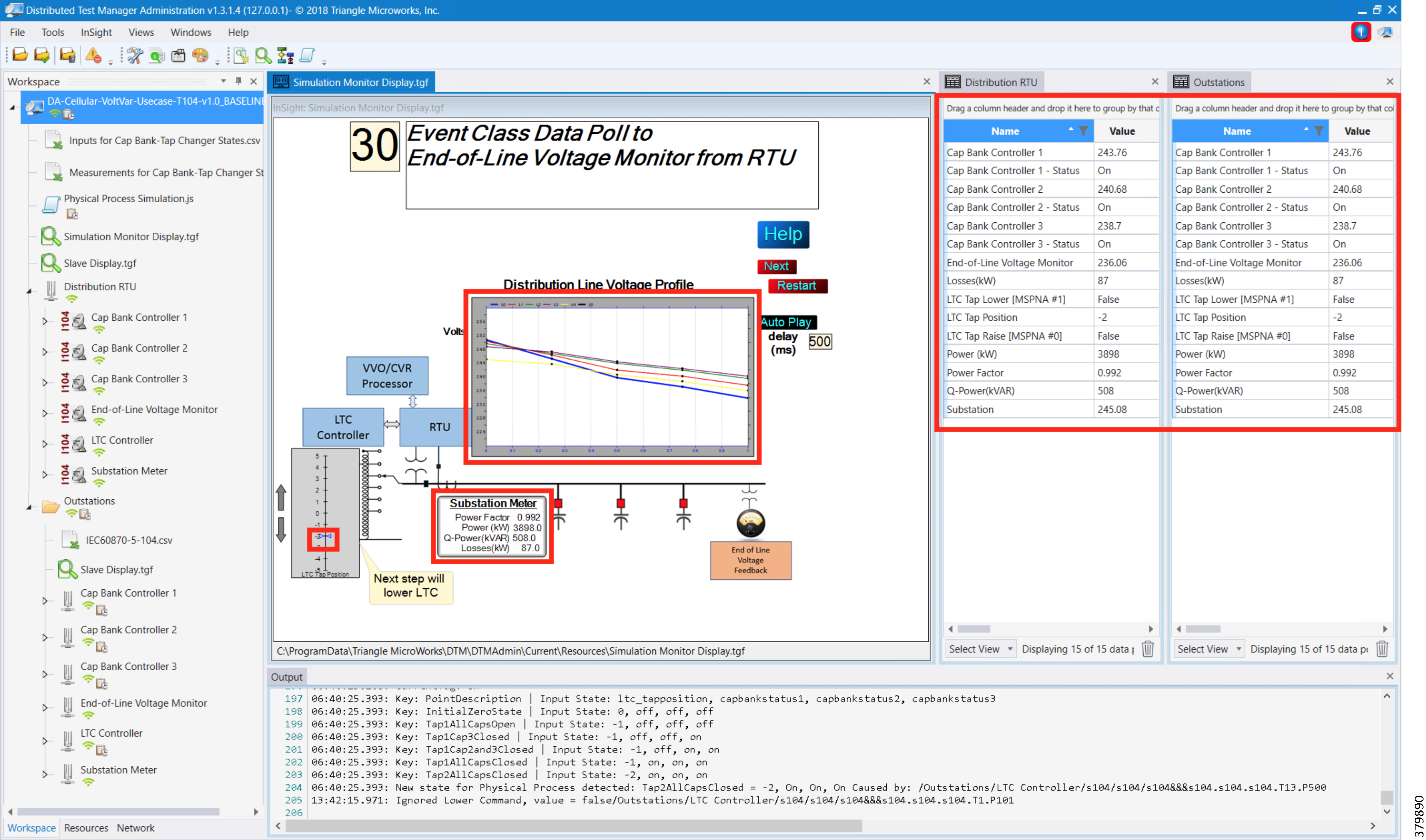

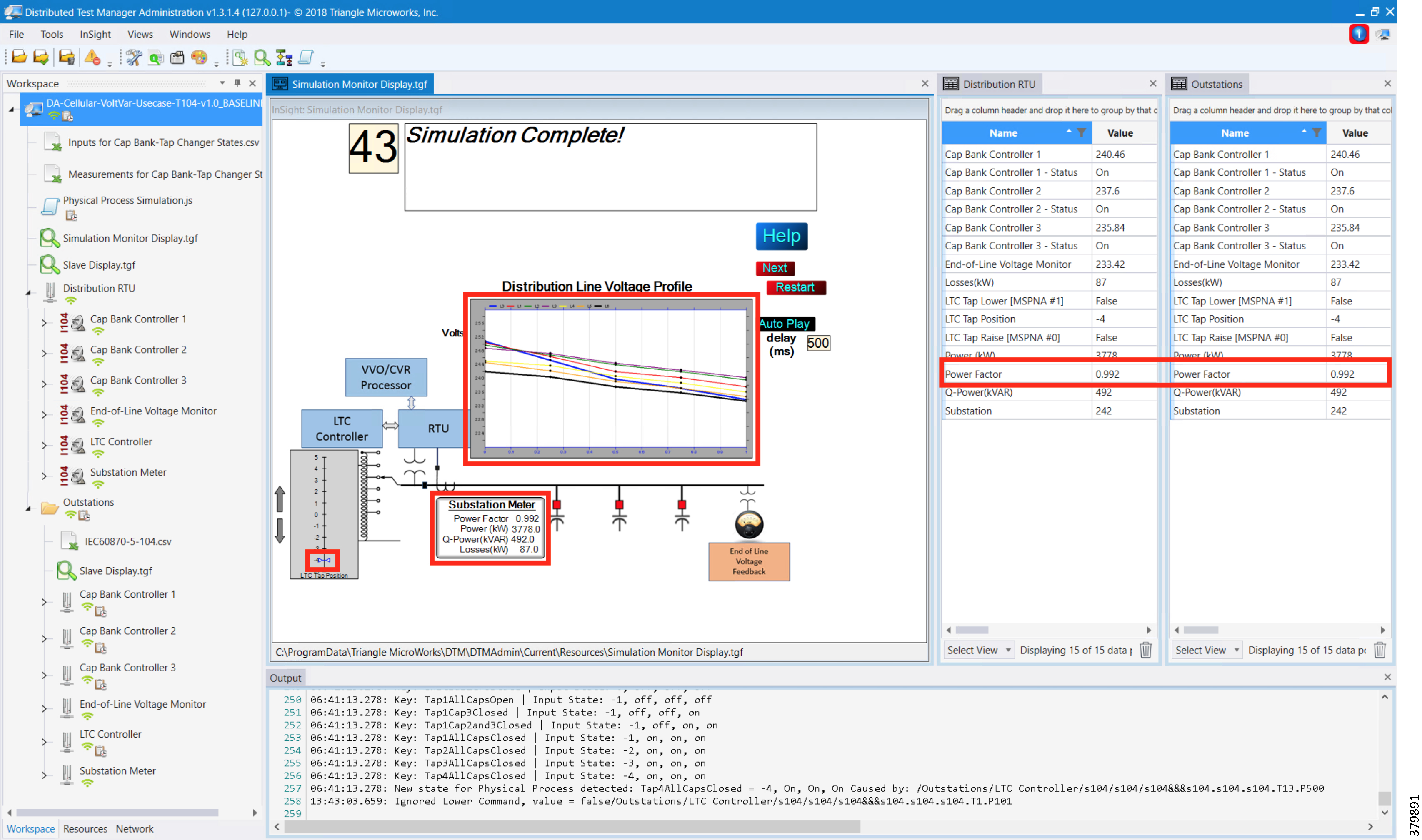

This implementation guide details the implementation of Distribution Automation use cases like FLISR, Volt/VAR and Secondary Substation monitoring for the Europe region. Therefore, the focus of this document is on IEC 60870-5-104 or T104 and IEC 60870-5-101 or T101 Supervisory Control and Data Acquisition (SCADA) protocols. We have planned a separate implementation guide that focuses on the North American Region distribution automation use cases.

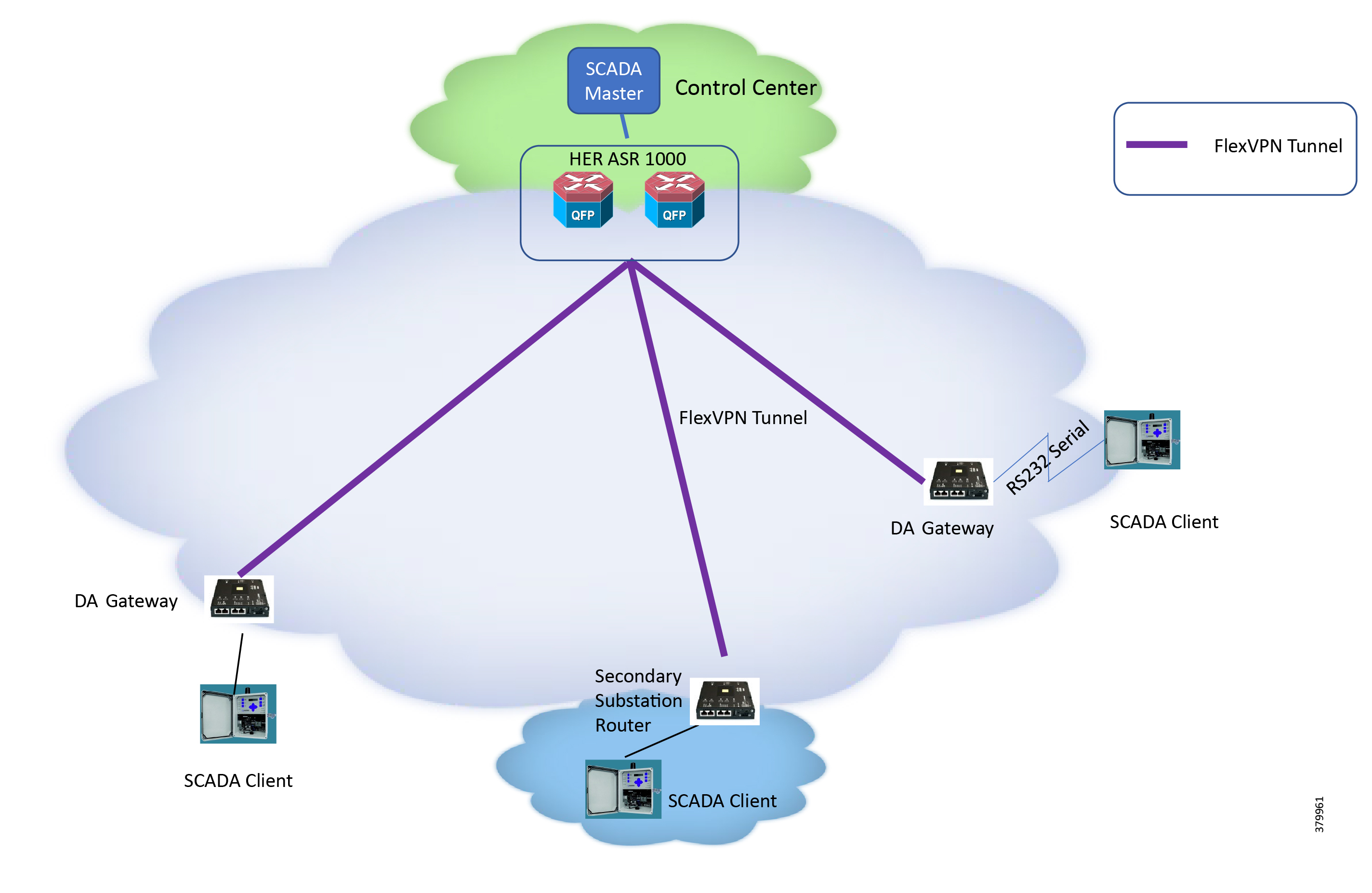

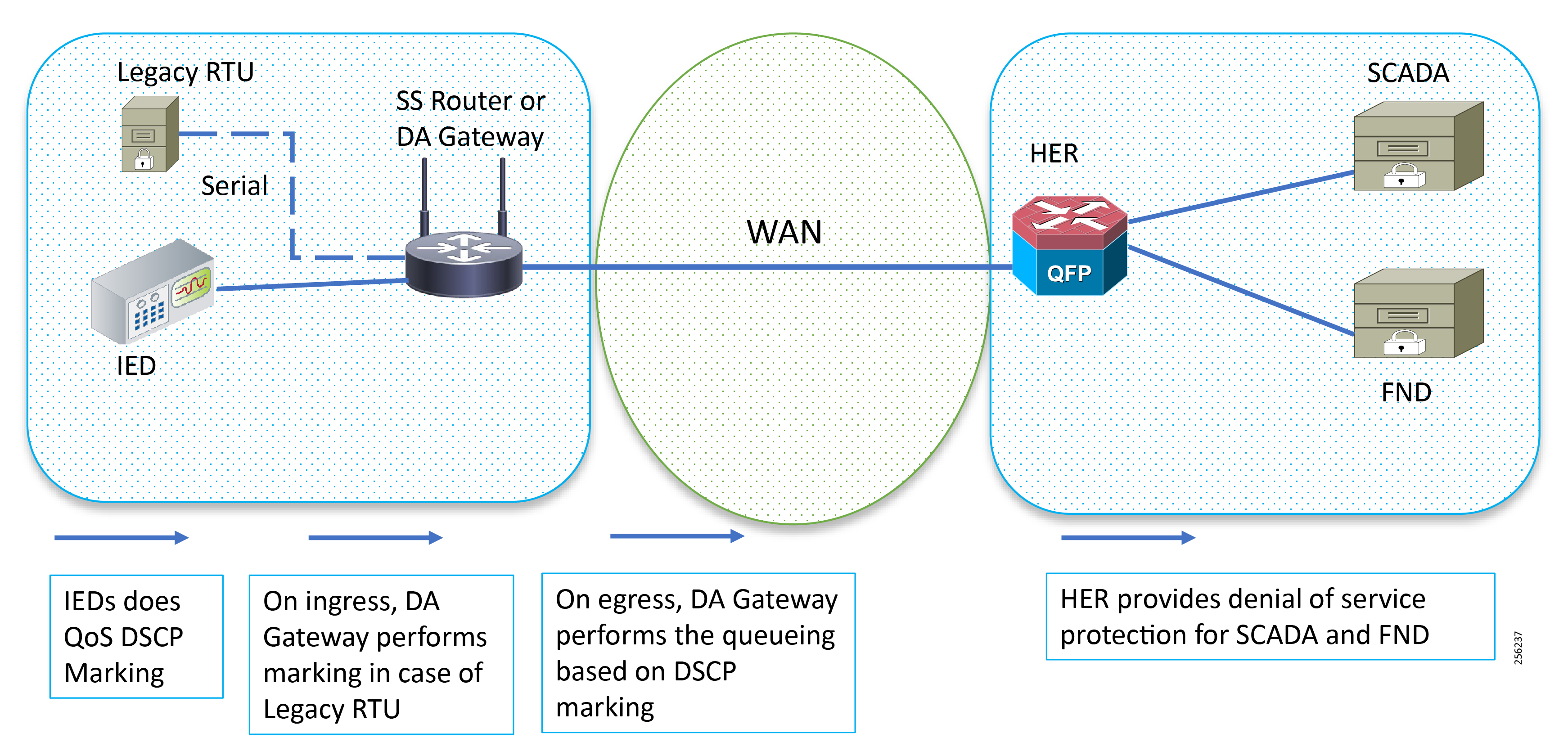

Secondary Substation monitoring covers both SCADA transport and SCADA translation scenarios. SCADA protocol translations are enabled on Cisco routers such as the Cisco IR1101, Cisco IR809, Cisco IR807, Cisco IR829, and CGR 1120. These routers are referred to as Secondary Substation Routers (SSR) or Distribution Automation Gateways (DA Gateways) throughout this document. Solution implementation is based on the design recommended in the Distribution Automation - Secondary Substation Design Guide that can be found at the following URL:

■![]() https://www.cisco.com/c/en/us/td/docs/solutions/Verticals/Distributed-Automation/Secondary-Substation/DG/DA-SS-DG.html

https://www.cisco.com/c/en/us/td/docs/solutions/Verticals/Distributed-Automation/Secondary-Substation/DG/DA-SS-DG.html

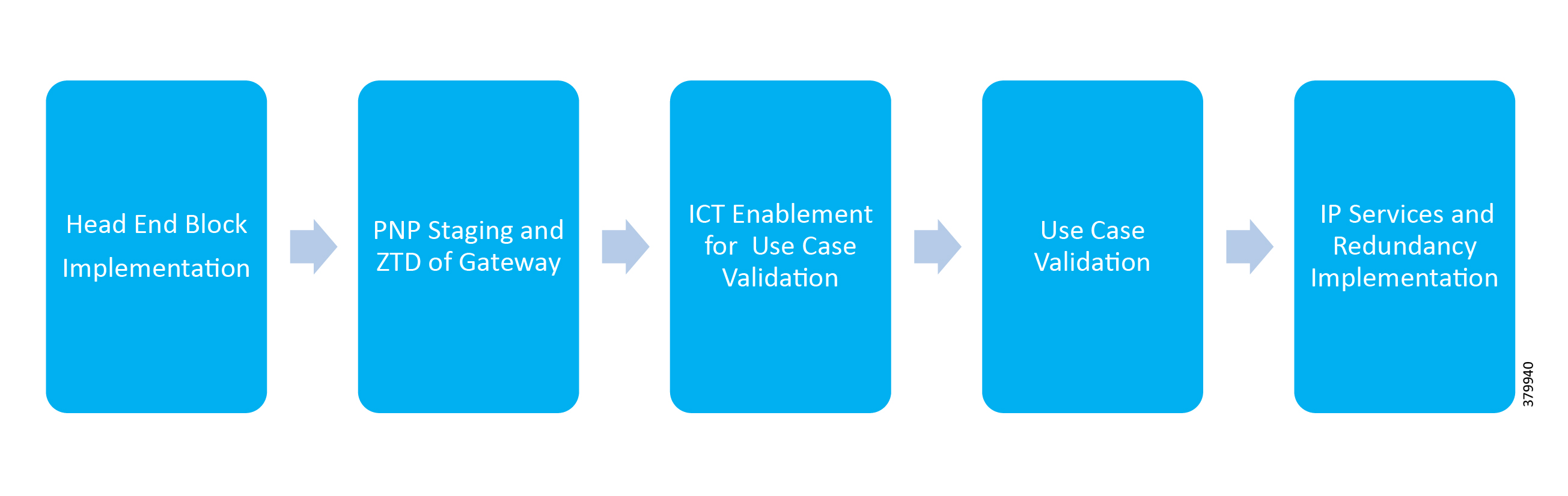

The flow of this implementation guide is depicted in Figure 1:

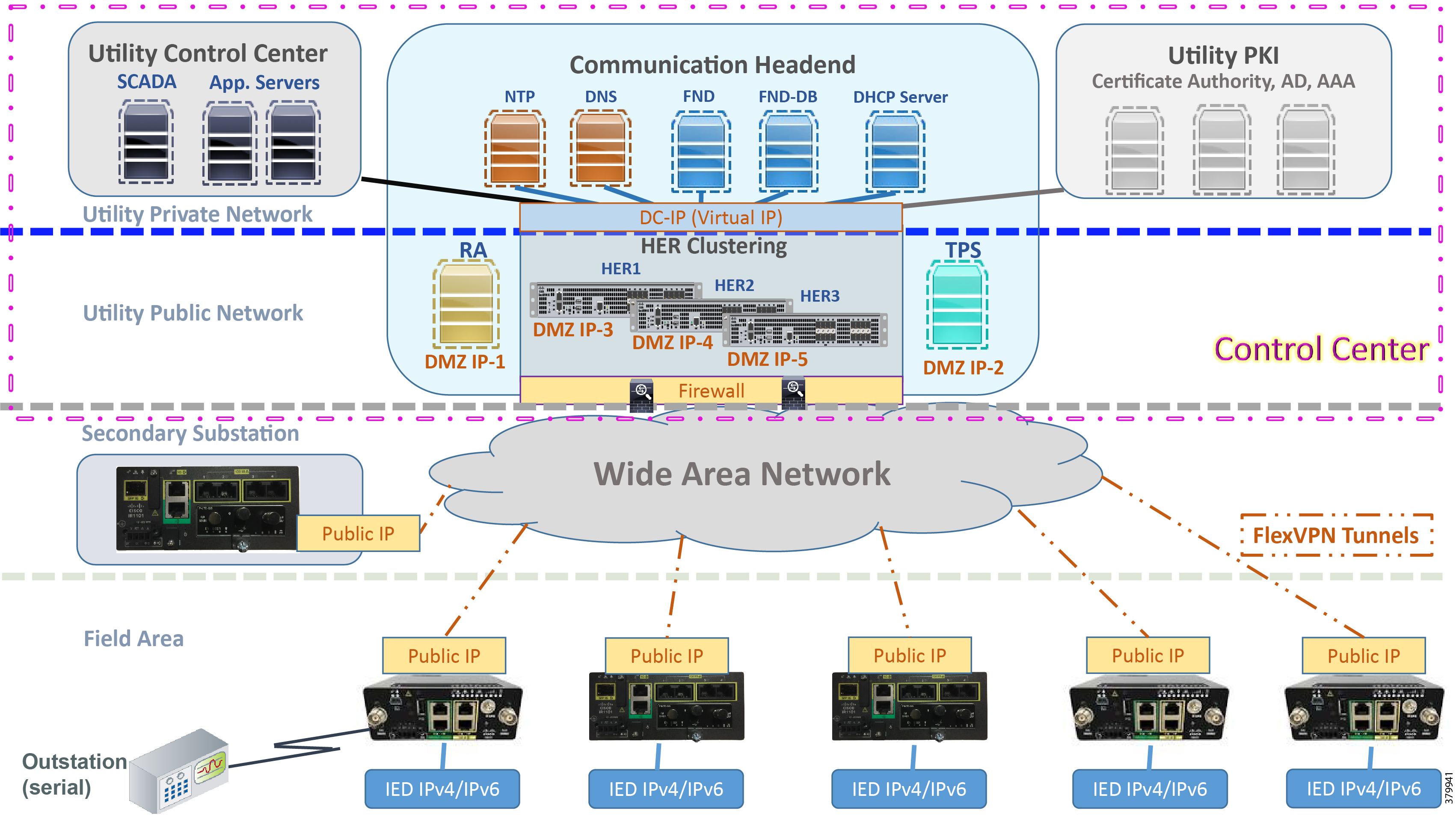

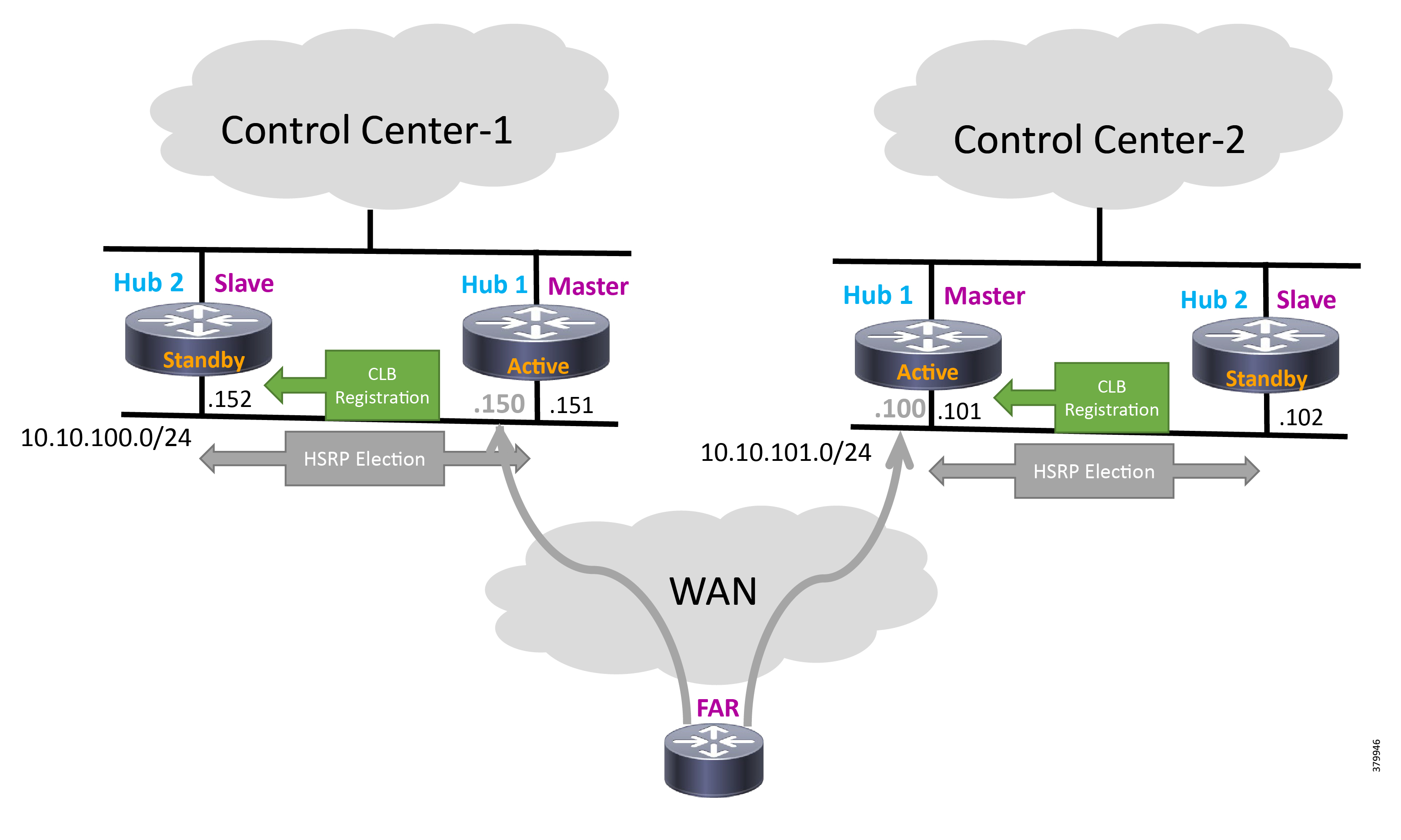

The Cisco Distribution Automation Solution is a two-tier architecture where the headend block is connected to the Field Area Network or Secondary Substation block using the WAN tier. The Gateway aggregates application traffic from the Field Area block and routes to the Headend block where the application resides. For a detailed description of different elements in the Field Area block and their implementation, please refer to the Cisco FAN - Headend Deep Dive Implementation and FAN Use Cases at the following URL:

■![]() https://docs.cisco.com/share/proxy/alfresco/url?docnum=EDCS-15726915

https://docs.cisco.com/share/proxy/alfresco/url?docnum=EDCS-15726915

Figure 2 Distribution Automation Solution Architecture

Gateways connect various outstation IEDs (IPV4/IPV6 or serial) in the Field Area or Secondary Substation via Ethernet and RS232/RS485 asynchronous serial interfaces. Solution Network Topology and Addressing discusses in detail the solution implementation topology, various IP address schemes used in different blocks, and VLAN segmentation across services. The gateway can be onboarded, staged, and deployed in Zero Touch fashion, which is the preferred and scalable way for deploying gateways.

The various stages involved in Zero Touch Deployment (ZTD) and best practices to be followed during ZTD implementation are discussed in detail in IoT Gateway Onboarding and Management discusses in detail. Once the gateways are registered to the Network Management Systems (NMS) Field Network Director (FND), gateways are provisioned with various features that will enable the secure bidirectional flow between IEDs in the field to SCADA applications in the Headend of the Distribution System Operator (DSO). Some of the application flow from the IEDs is via the Remote Terminal Unit (RTU) residing in the Secondary Substation to the SCADA.

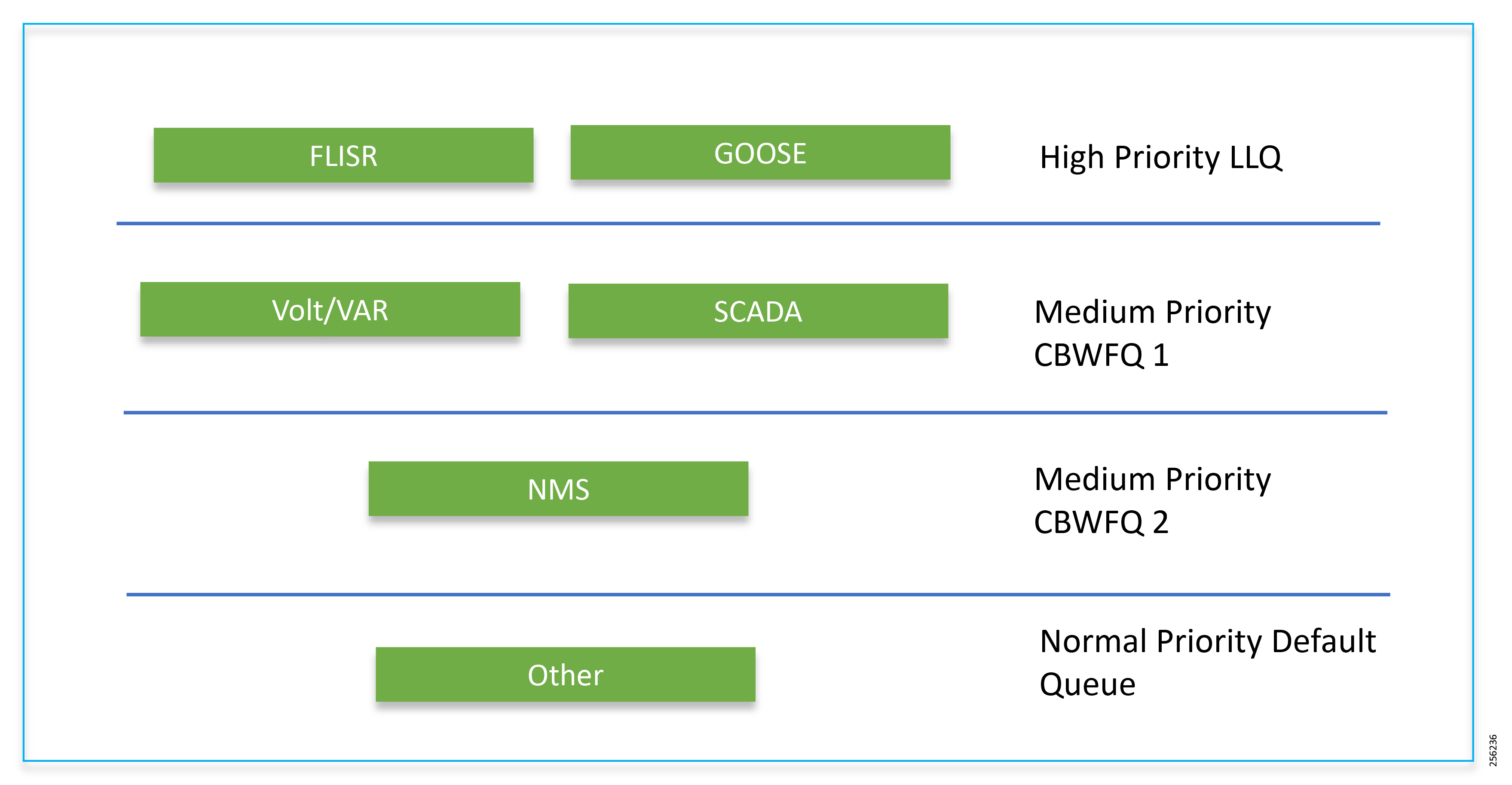

Features can be broadly classified into horizontal ones like IP routing, network encryption, time synchronization (like NTP), QoS, NAT, and DHCP and vertical features like protocol translation, raw sockets, and IED-based ACLs. Appendix A: PnP Profiles provides customized and well-tested use case-based NMS templates, which is key for faster field deployment of Distribution Automation use cases.

Application Use Cases

This document addresses the following technology use cases:

Solution Network Topology and Addressing

This chapter, which discusses the various topologies used for solution validation and implementation in this guide, includes the following major topics:

■![]() Addressing in DSO Control Center2

Addressing in DSO Control Center2

Topology Diagram

This section describes the high-level solution validation topology that has been used in this Secondary Substation Implementation Guide.

High Level Solution Validation Topology

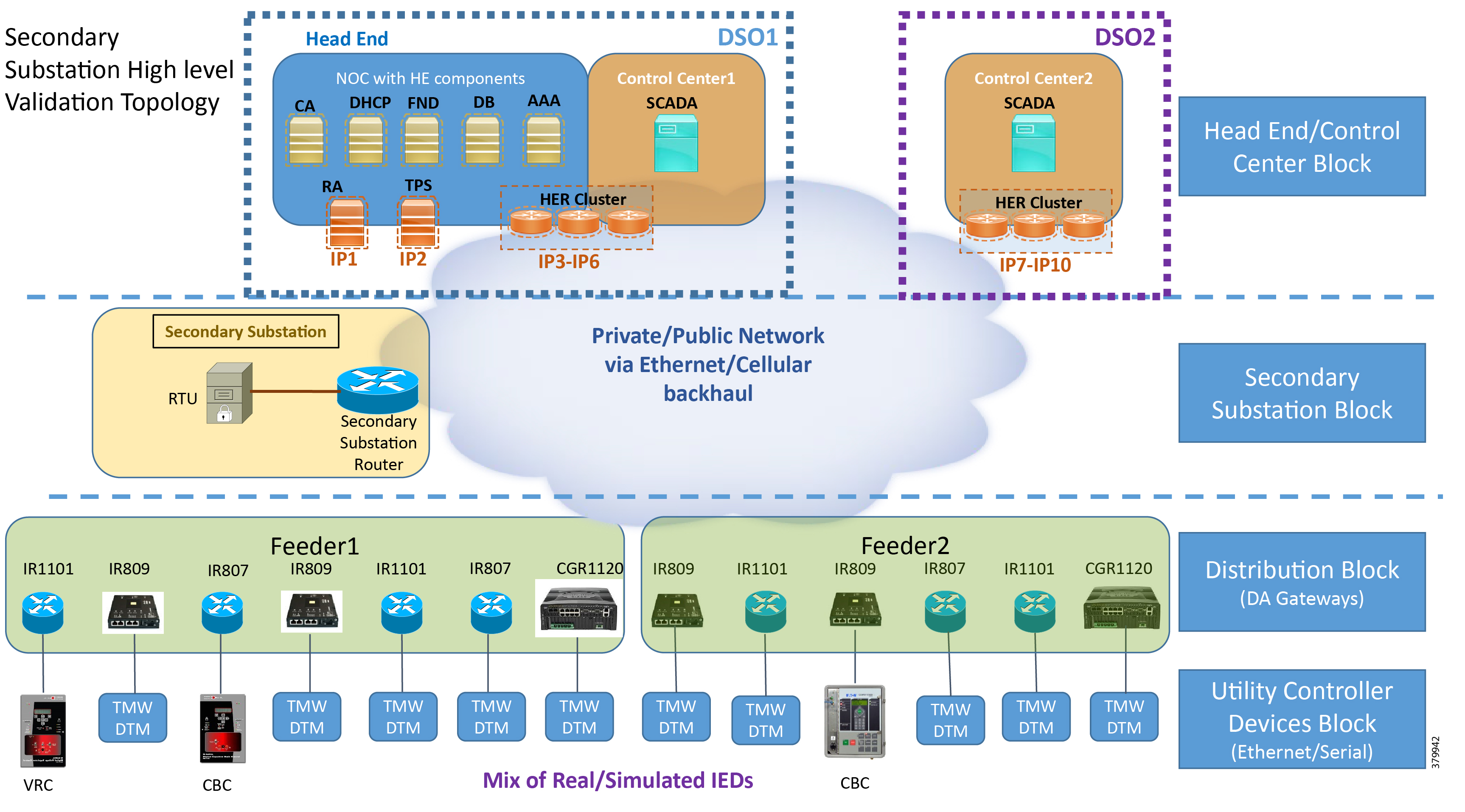

Figure 3 depicts the high level solution validation topology:

Figure 3 Secondary Substation High Level Solution Validation Topology

The multiple layers of topology include:

1.![]() Head End/Control Center Block, which hosts the DSO Control Center1 (DSO1) and DSO Control Center2 (DSO2):

Head End/Control Center Block, which hosts the DSO Control Center1 (DSO1) and DSO Control Center2 (DSO2):

a.![]() Both Control Centers host the SCADA application server. They could also host other application servers.

Both Control Centers host the SCADA application server. They could also host other application servers.

b.![]() Of the two Control Centers, DSO1 hosts the following additional components:

Of the two Control Centers, DSO1 hosts the following additional components:

- CA, Active Directory (AD), Dynamic Host Configuration Protocol (DHCP), Field Network Director (FND), Authentication, Authorization, and Accounting (AAA), Registration Authority (RA), and Tunnel Provisioning Server (TPS).

- These components are essential for the ZTD of the SSRs that are positioned in the Secondary Substation and DA Gateways that are positioned along the Distribution Feeder.

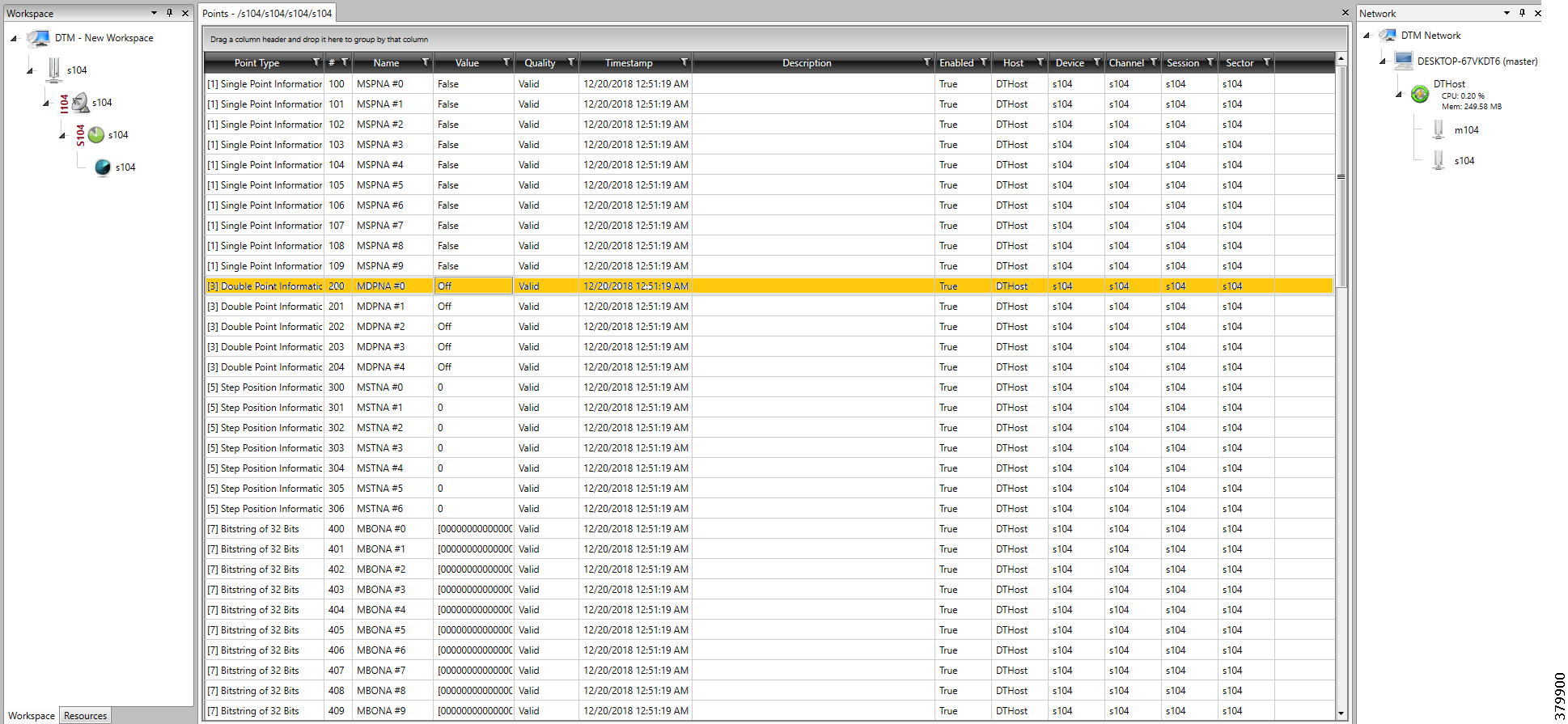

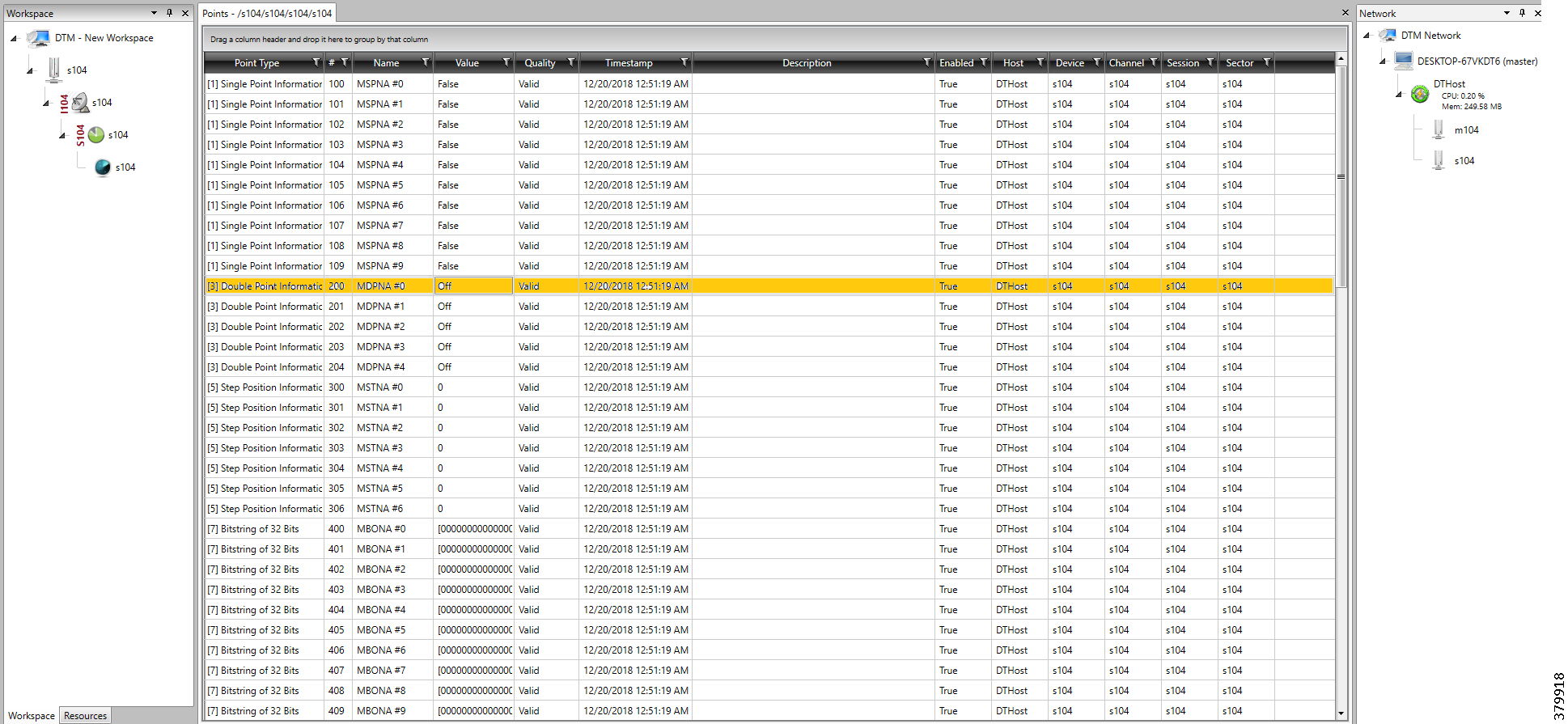

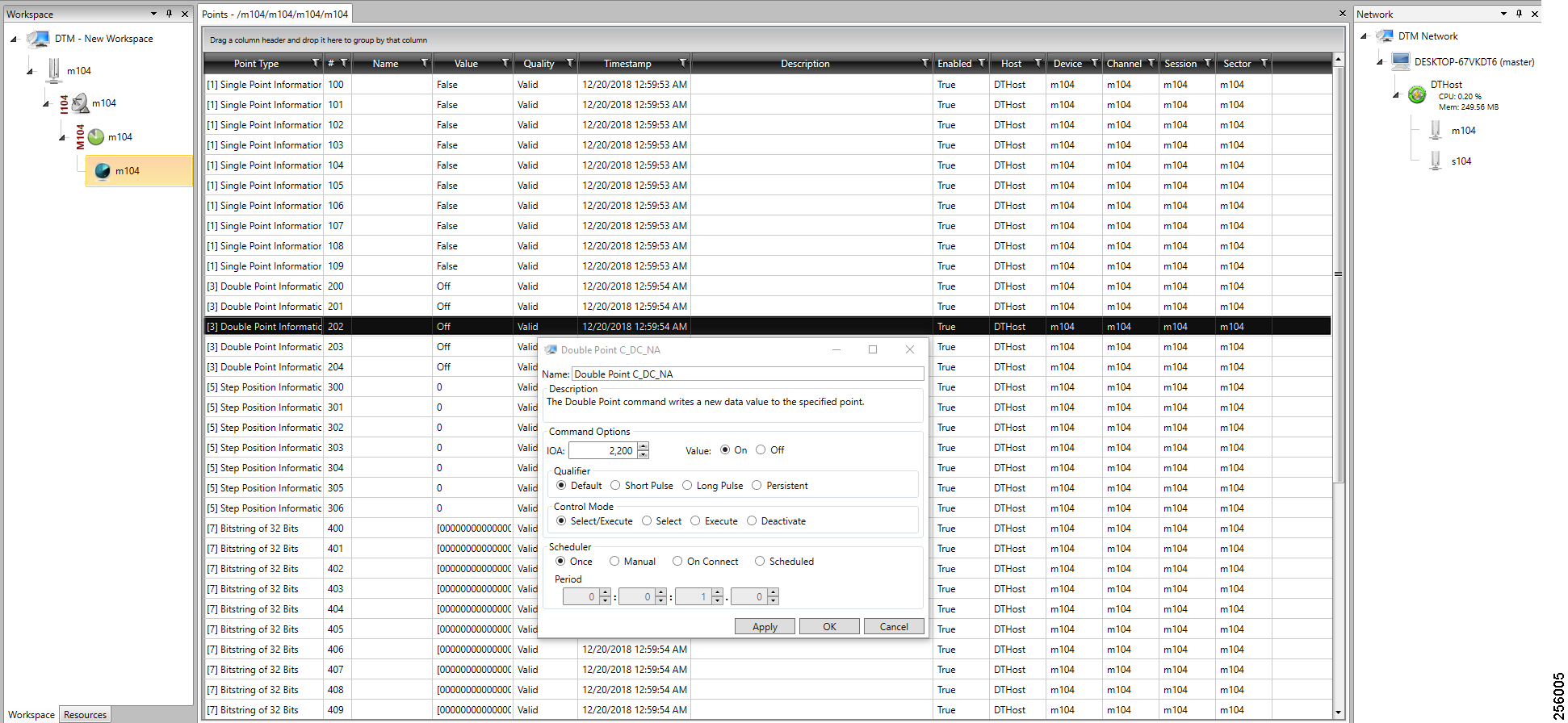

4.![]() Utility Controller Devices Block. Utility controller devices (real/simulated) are connected to the DA Gateways over a Ethernet/Serial interface.

Utility Controller Devices Block. Utility controller devices (real/simulated) are connected to the DA Gateways over a Ethernet/Serial interface.

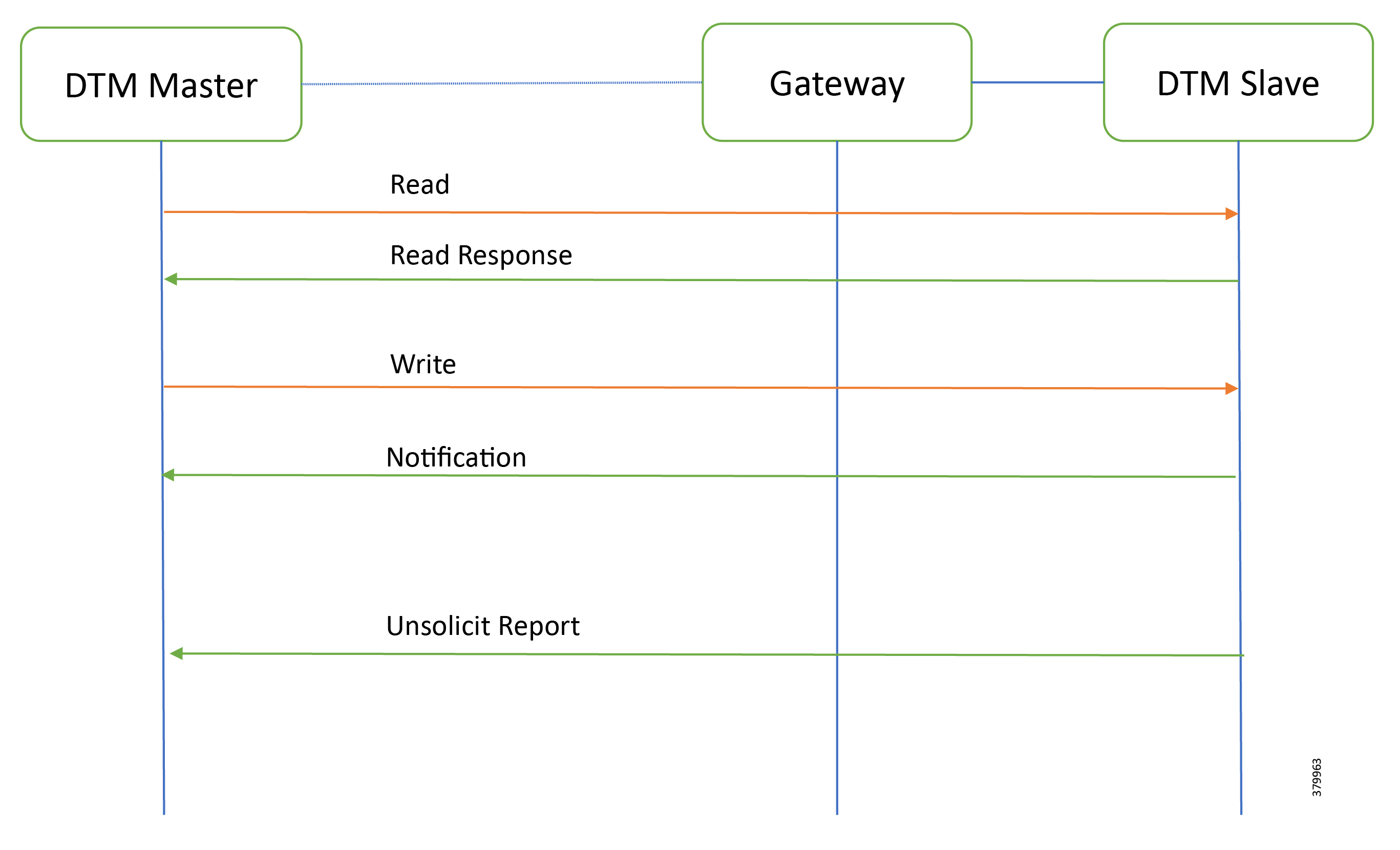

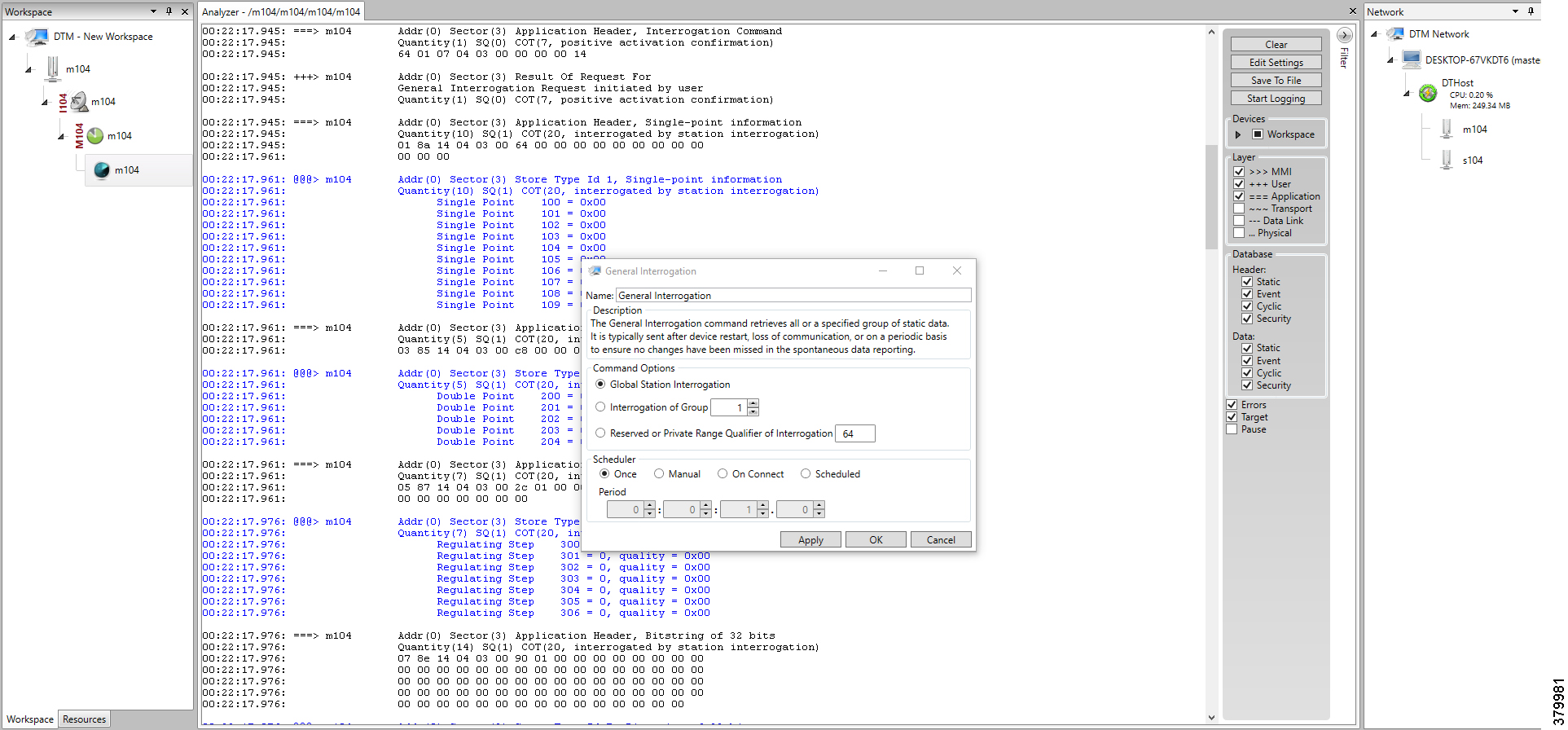

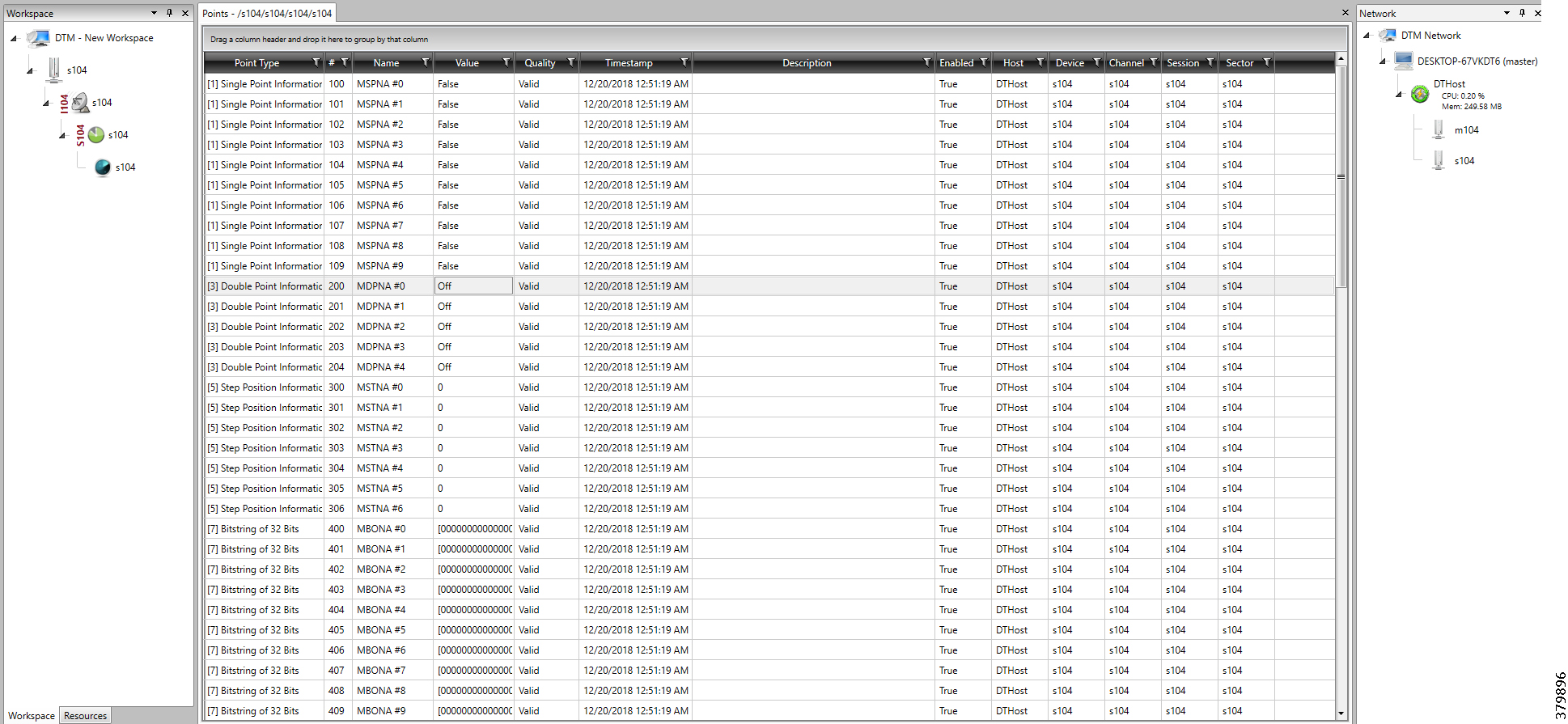

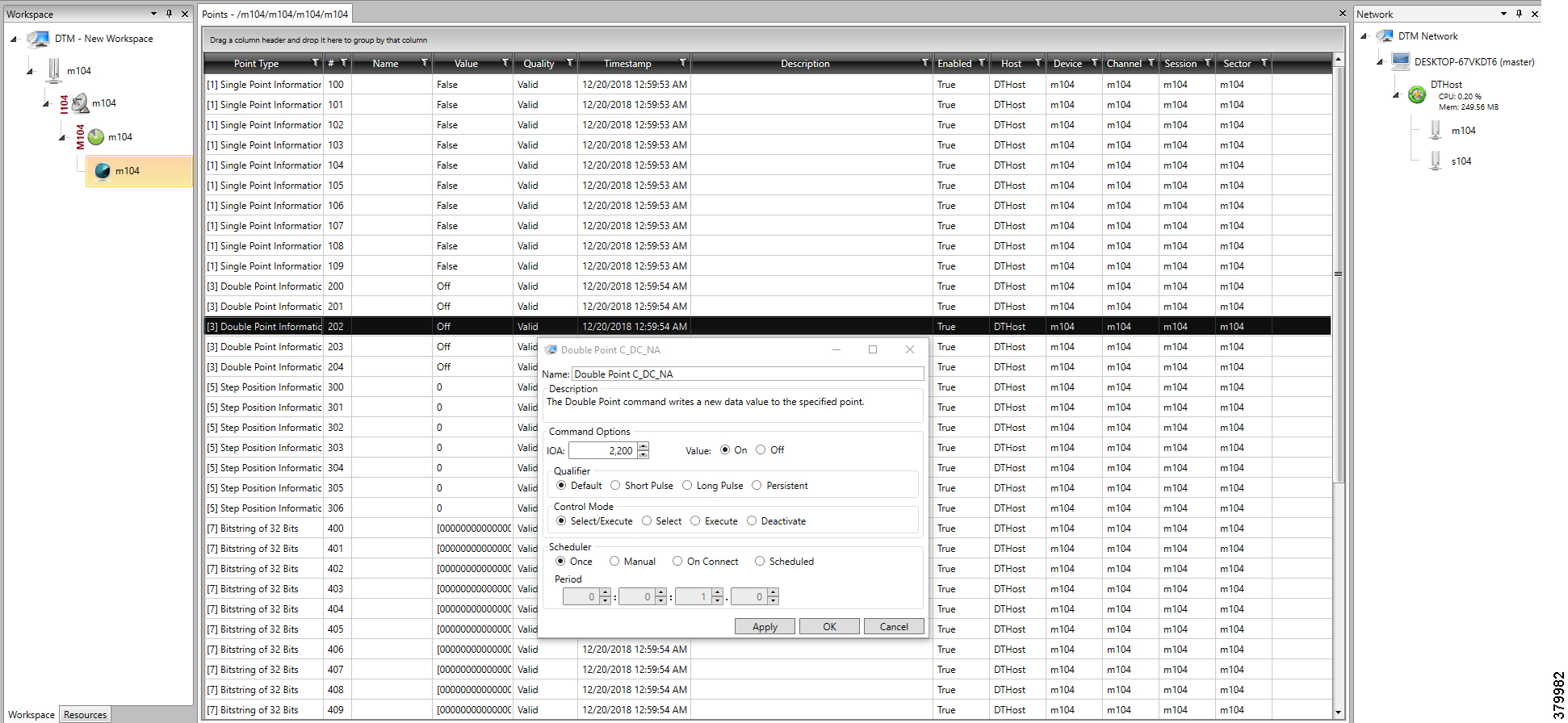

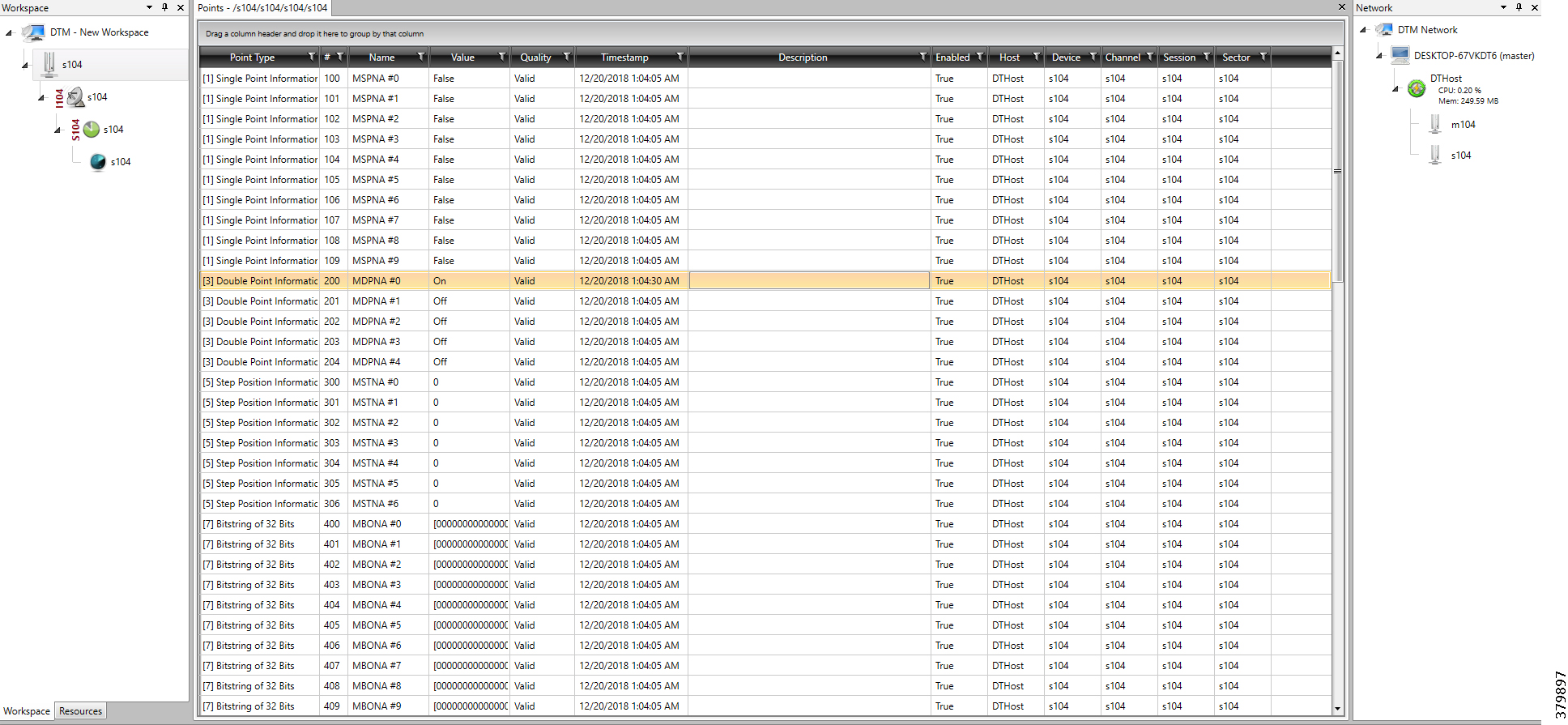

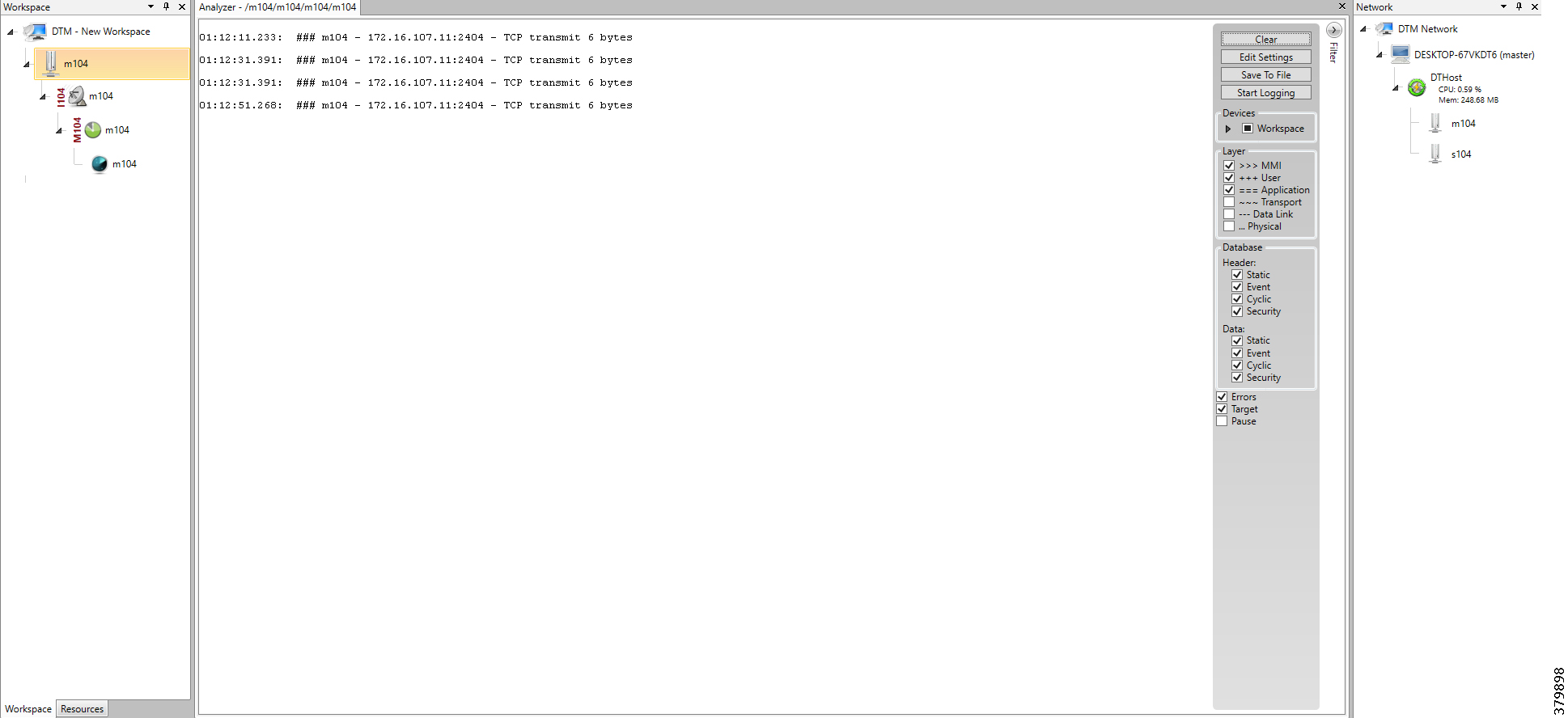

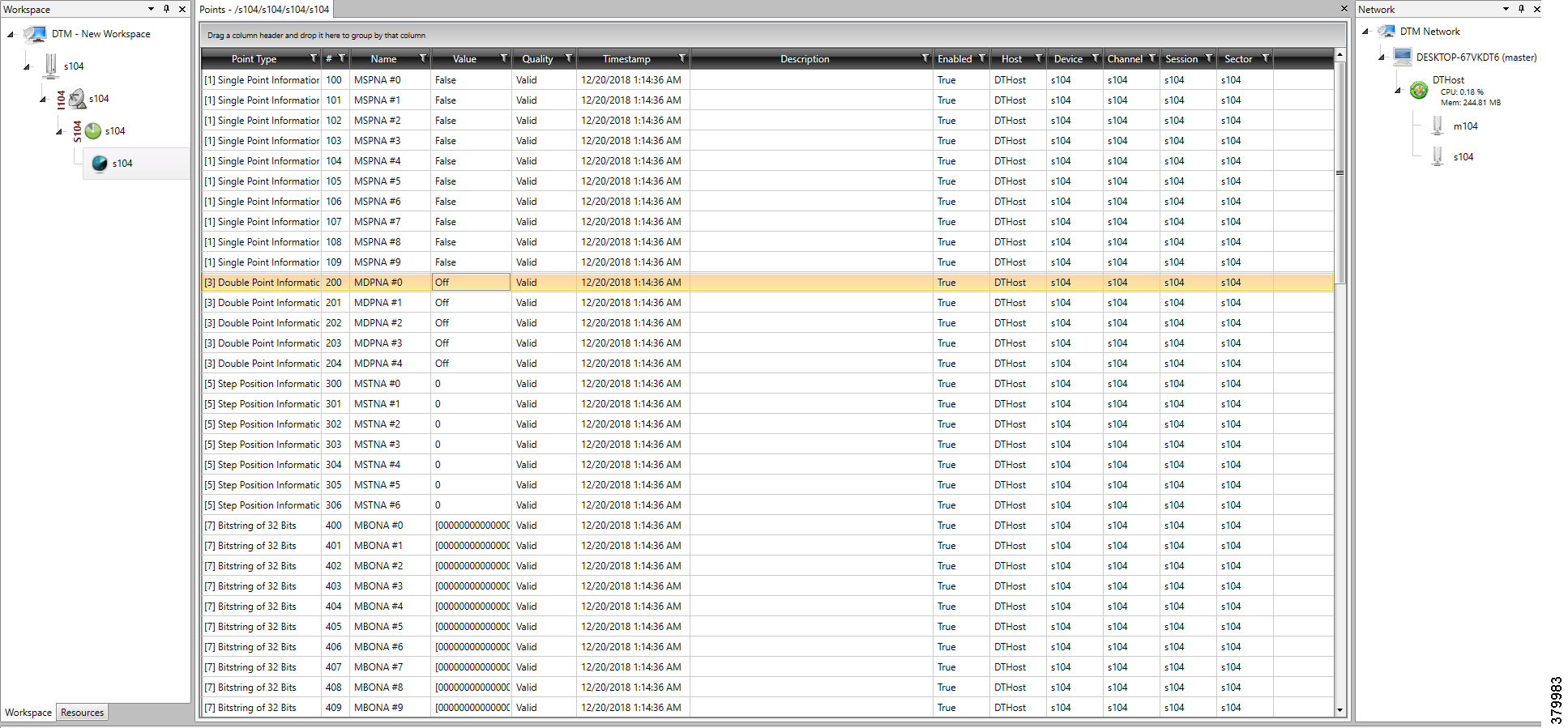

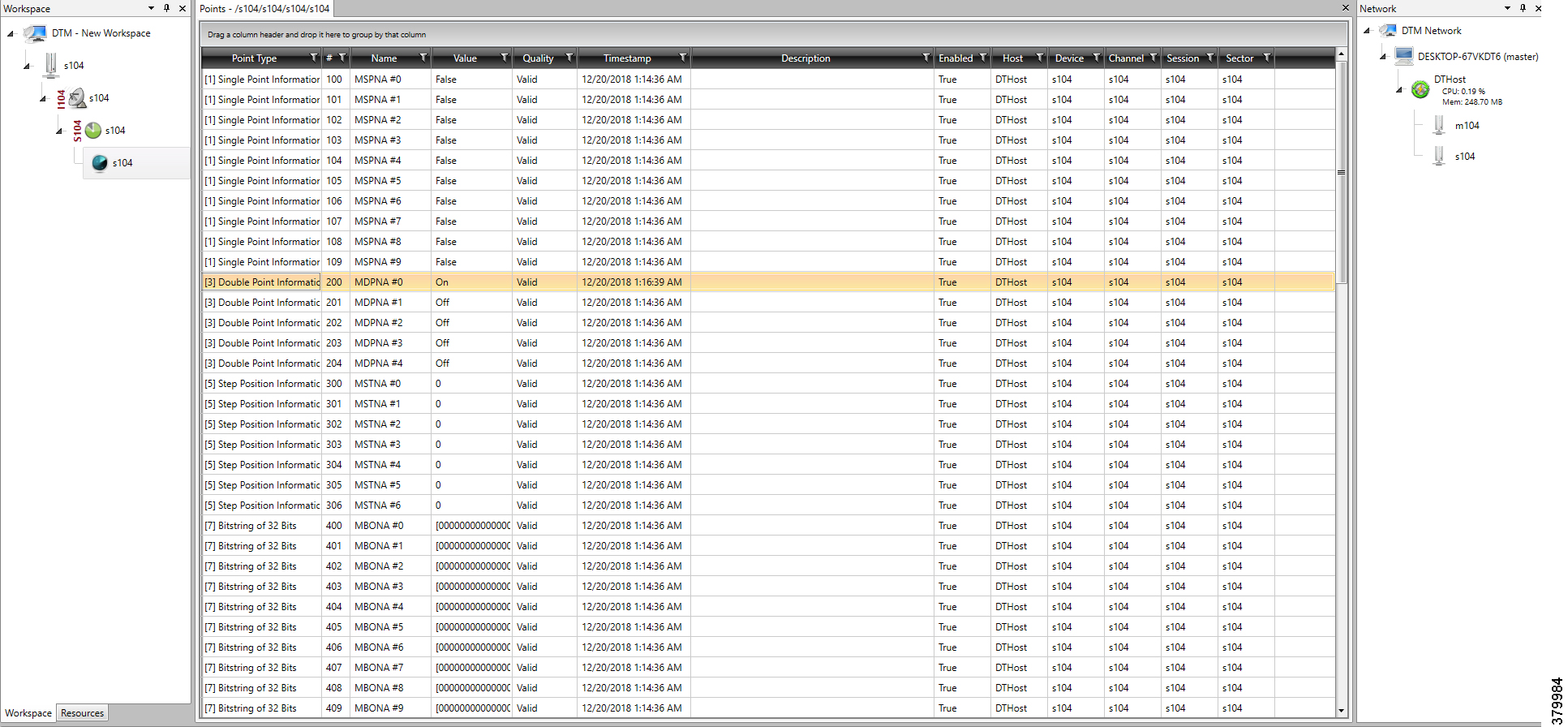

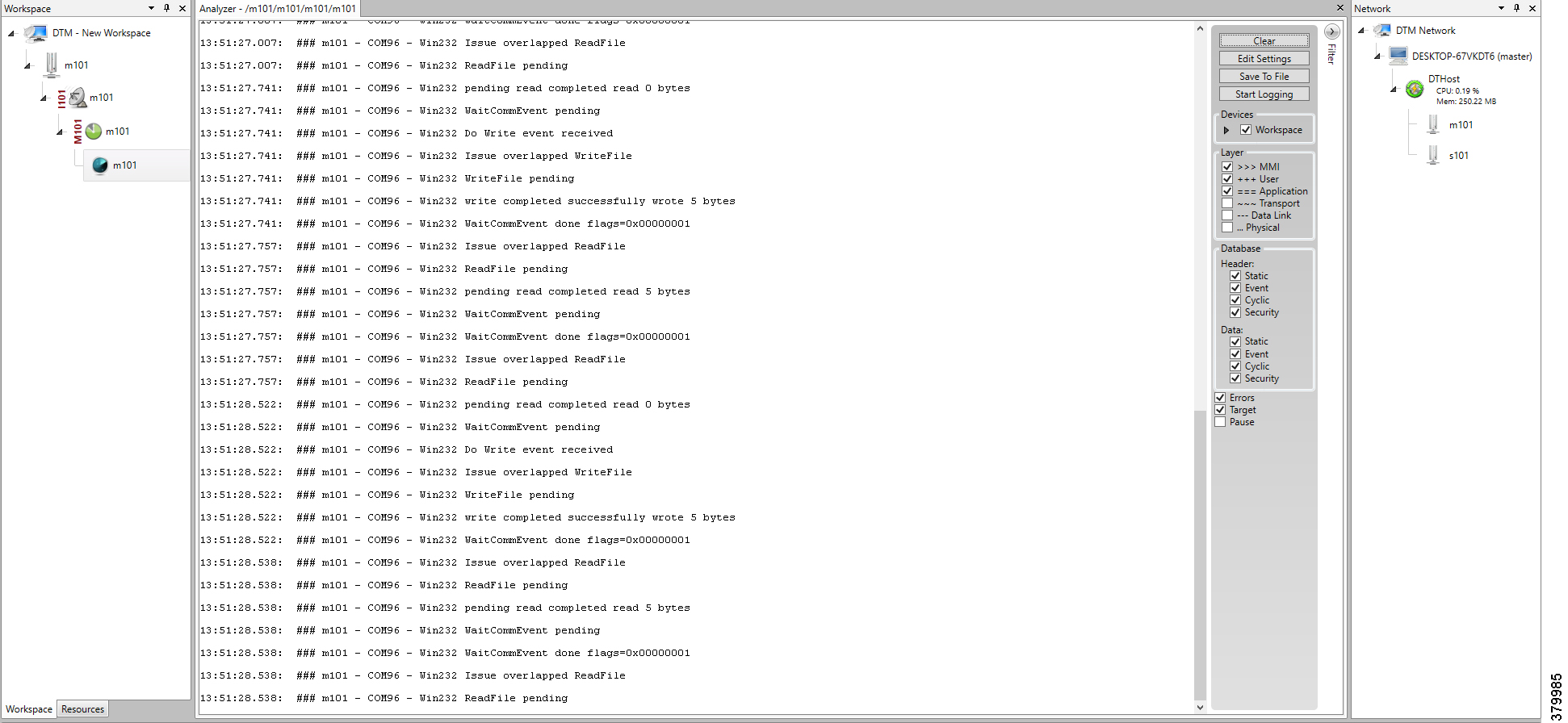

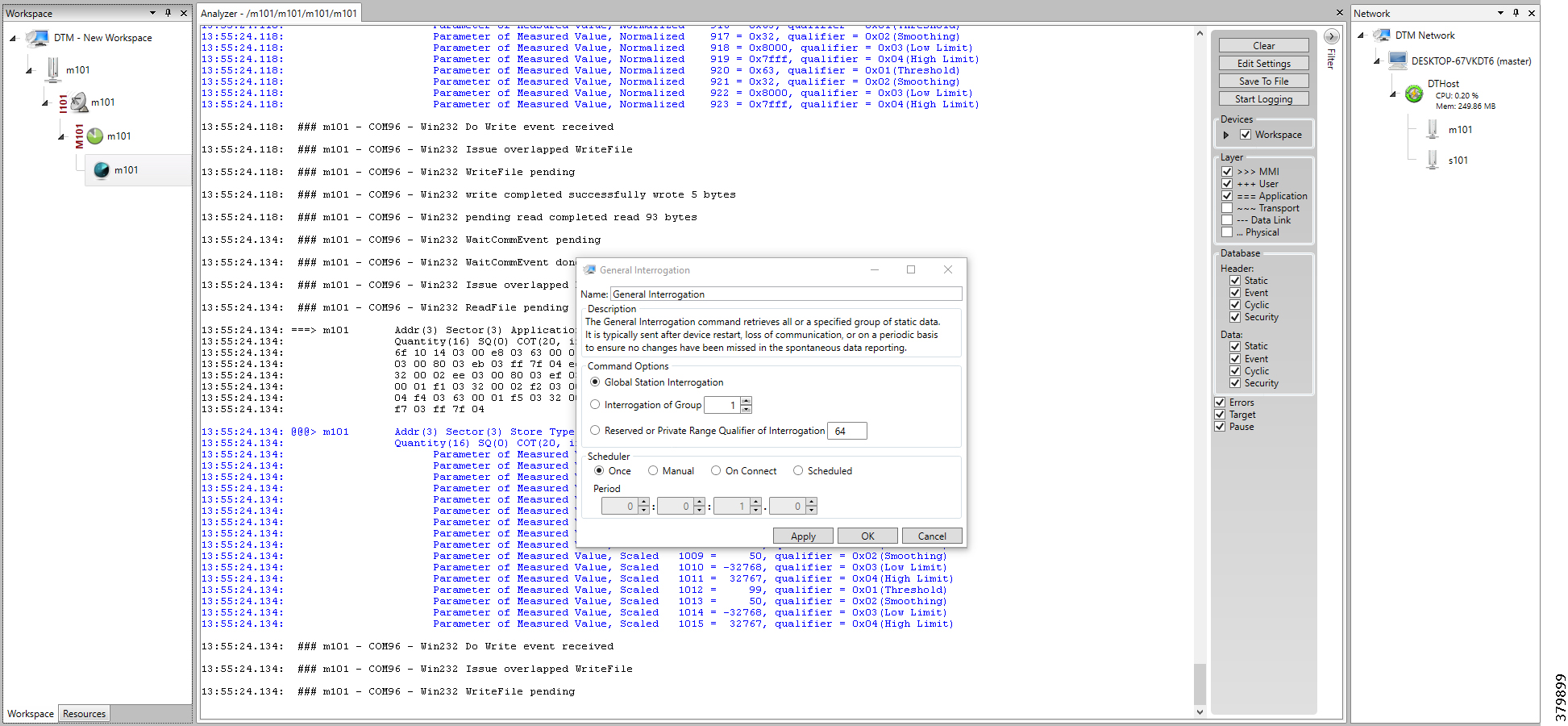

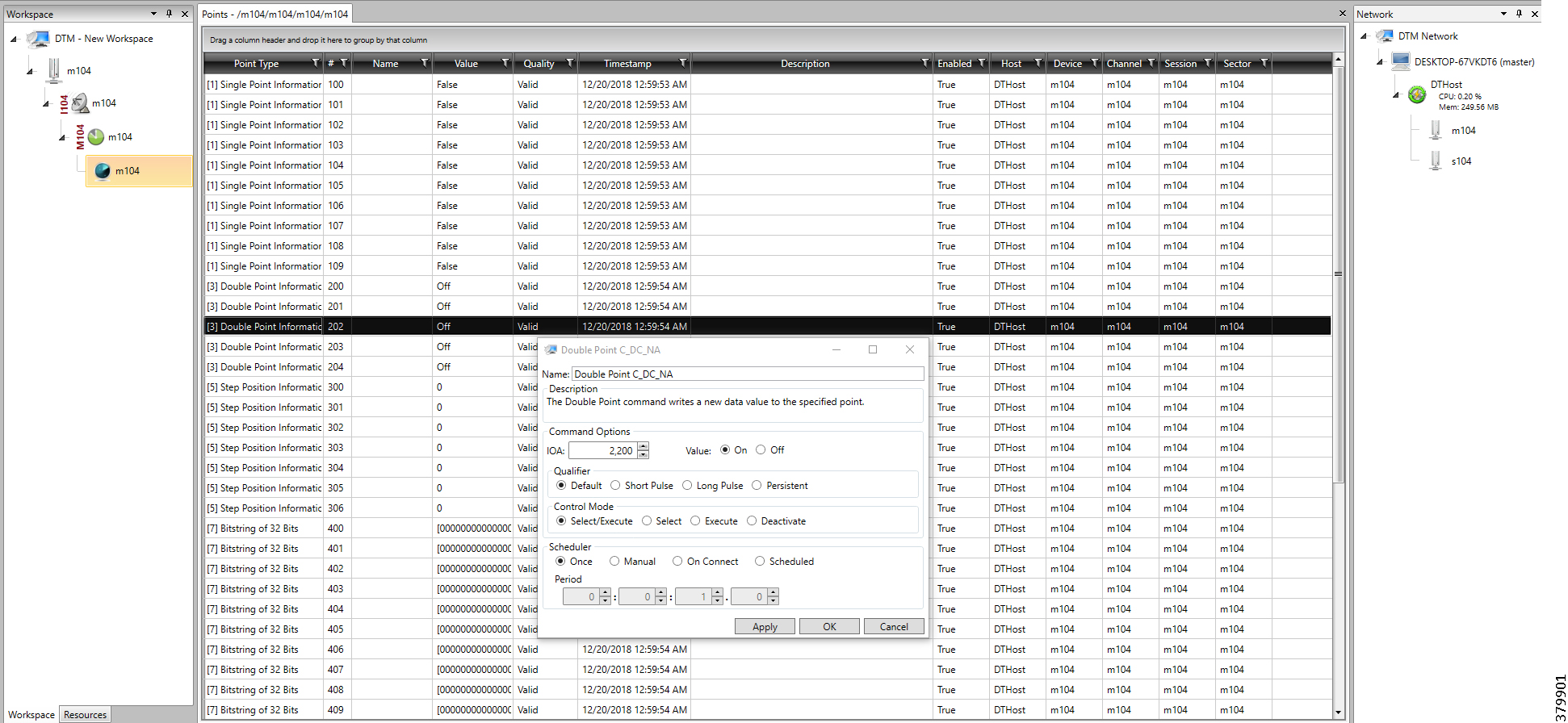

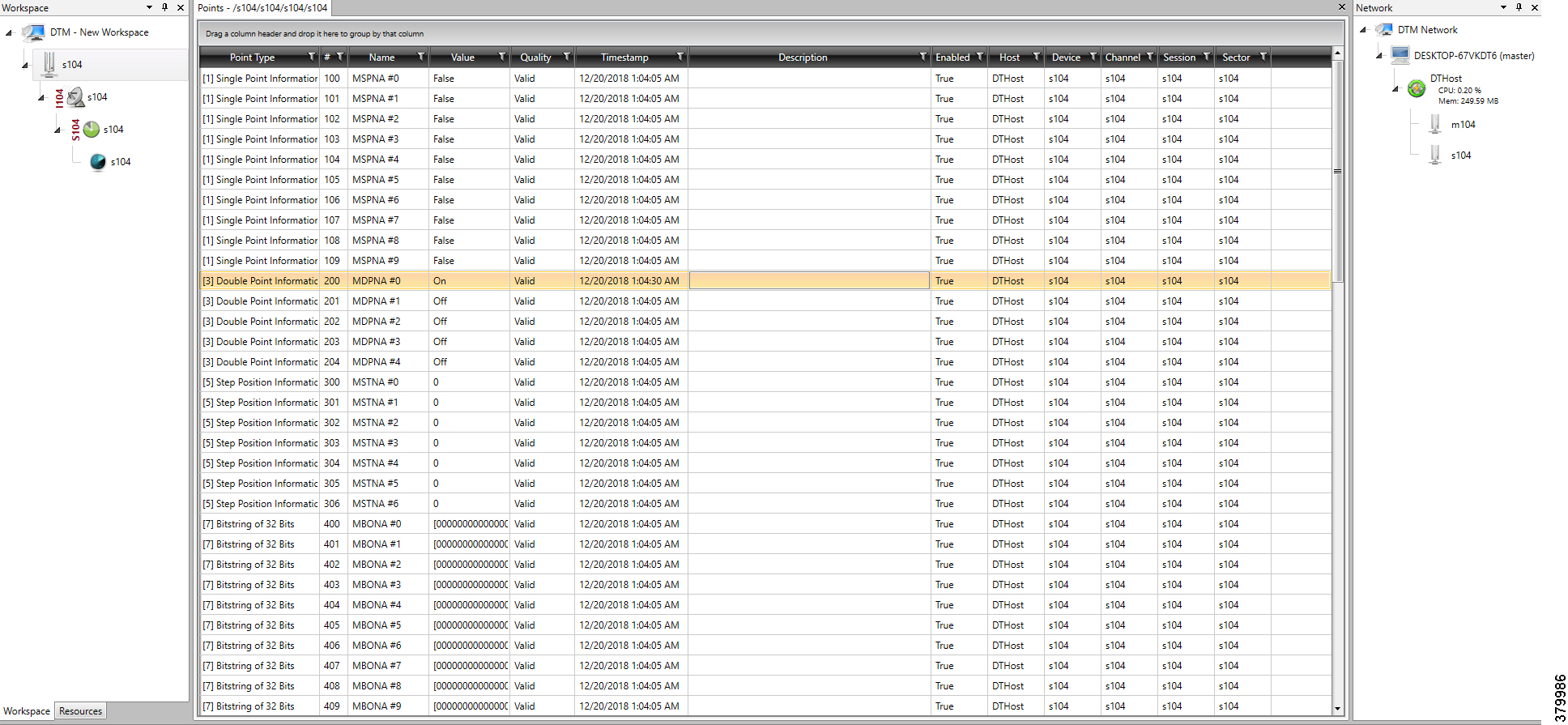

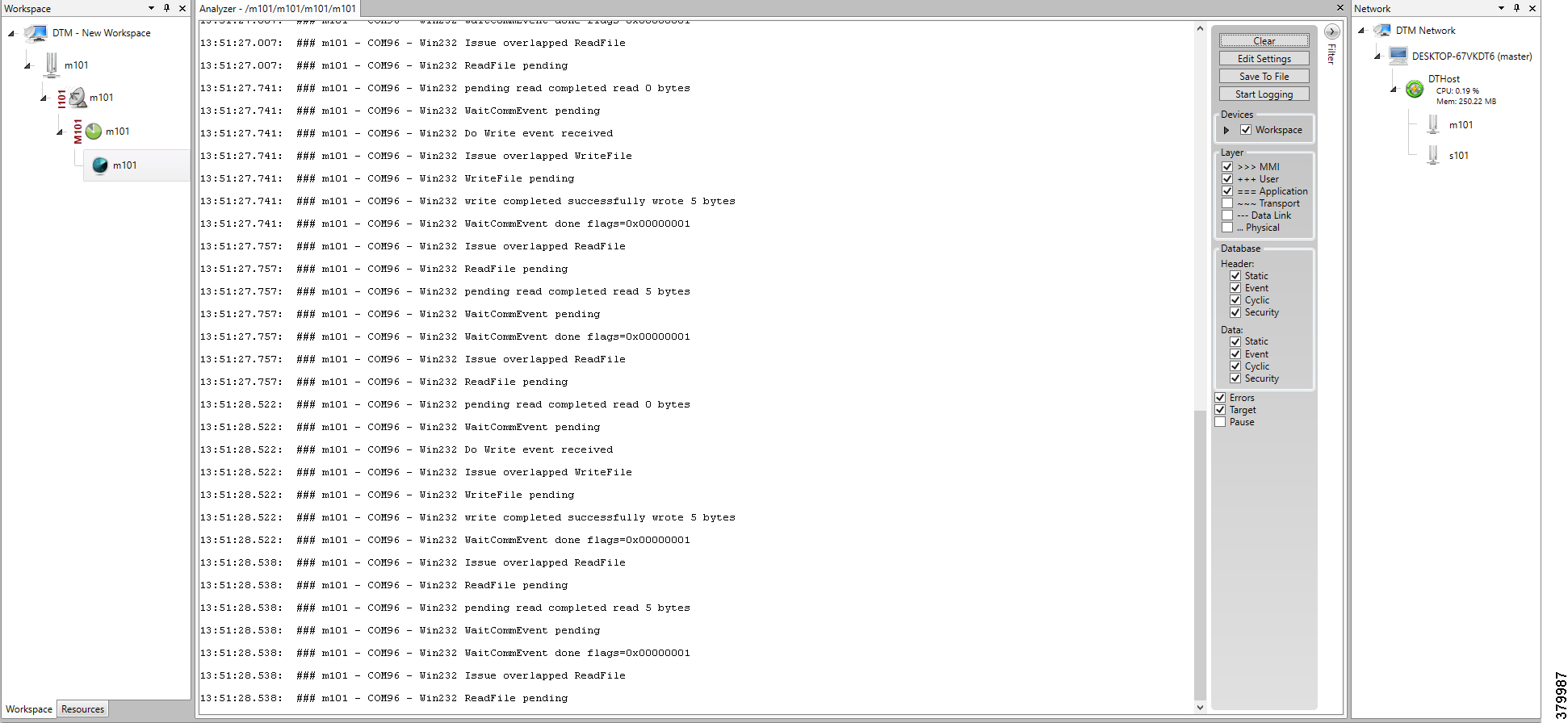

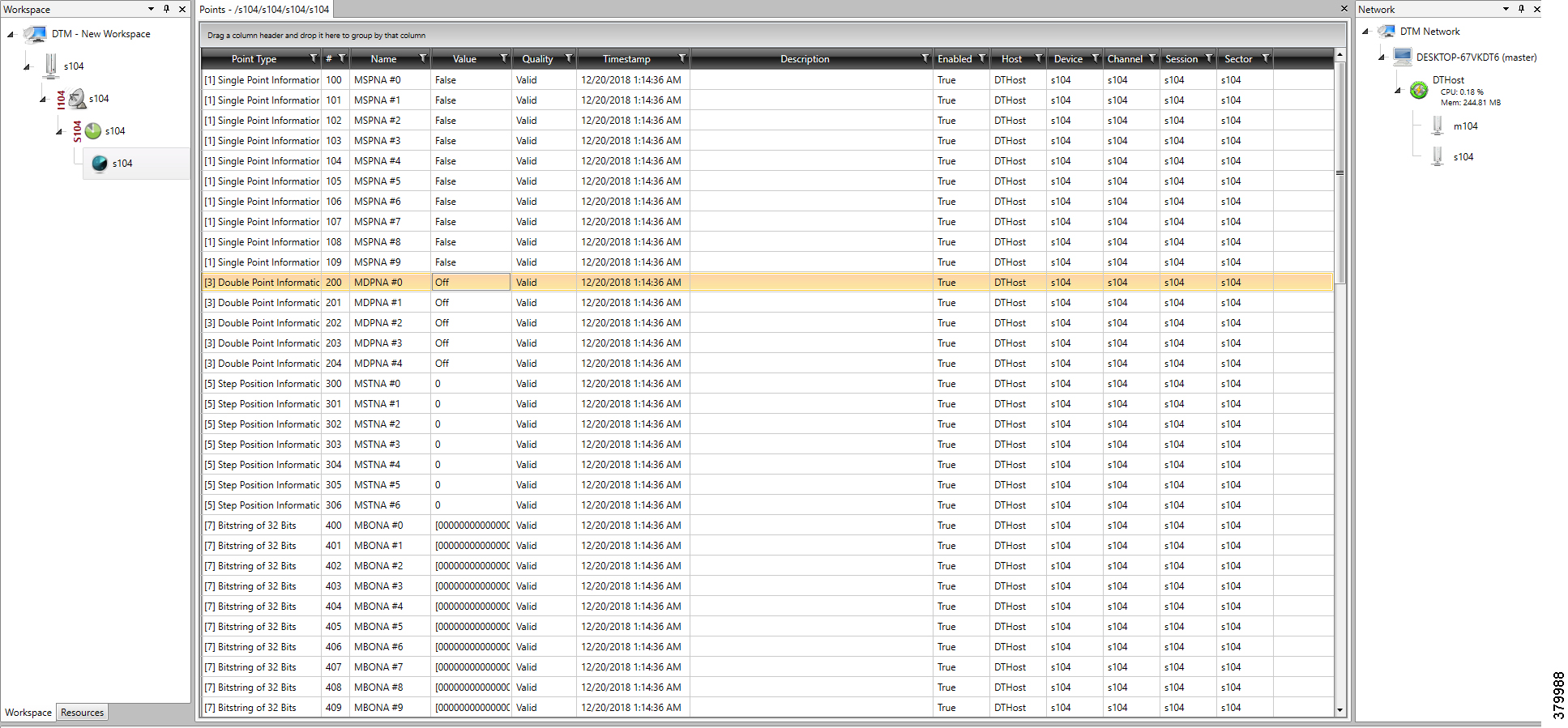

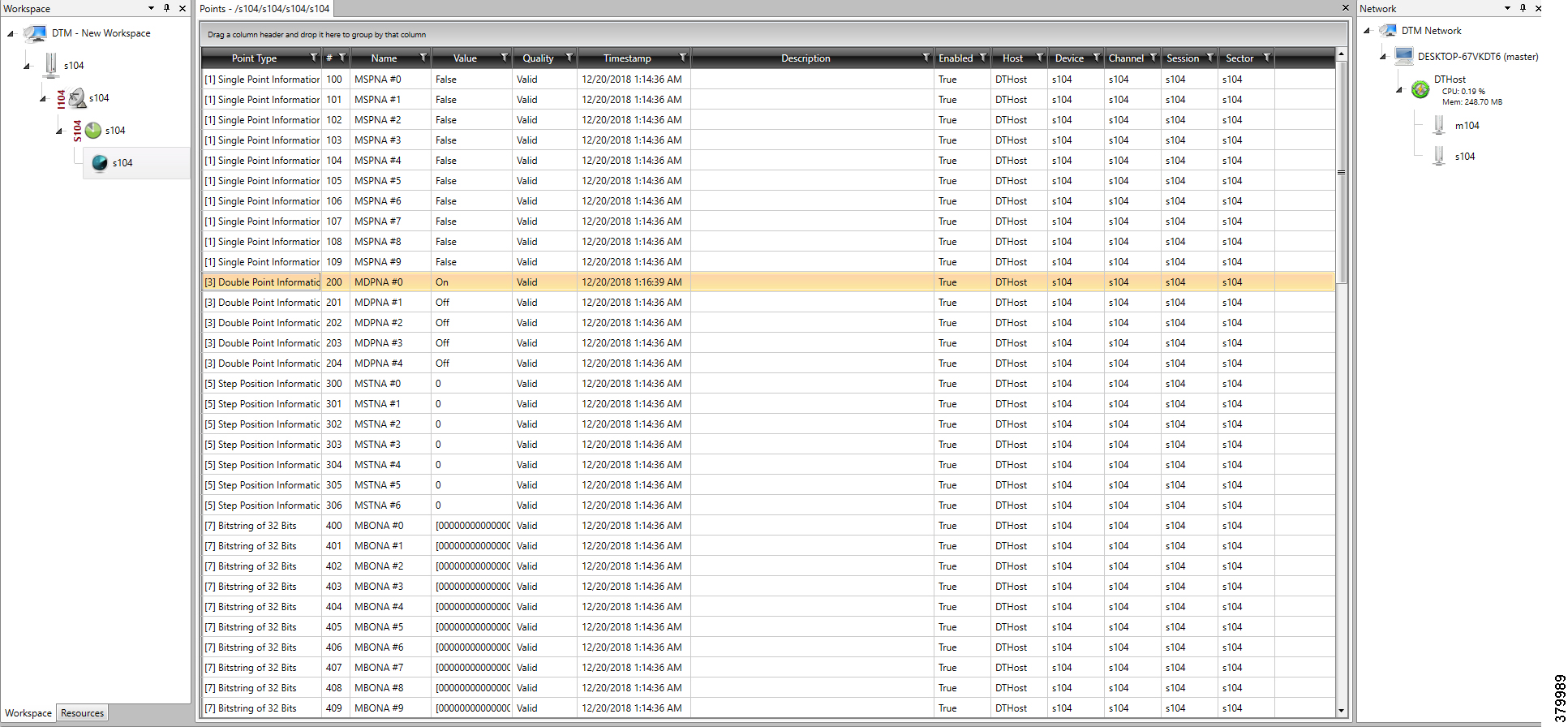

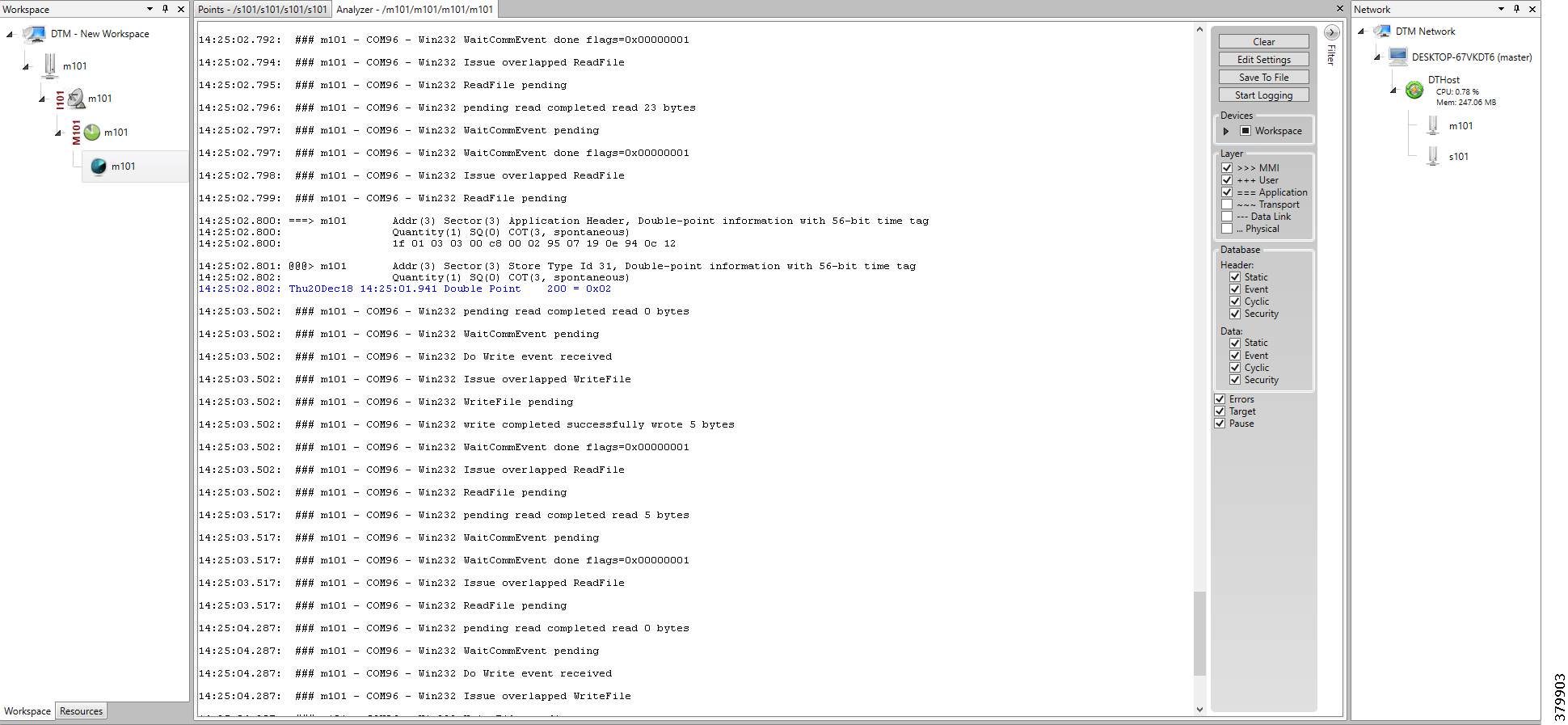

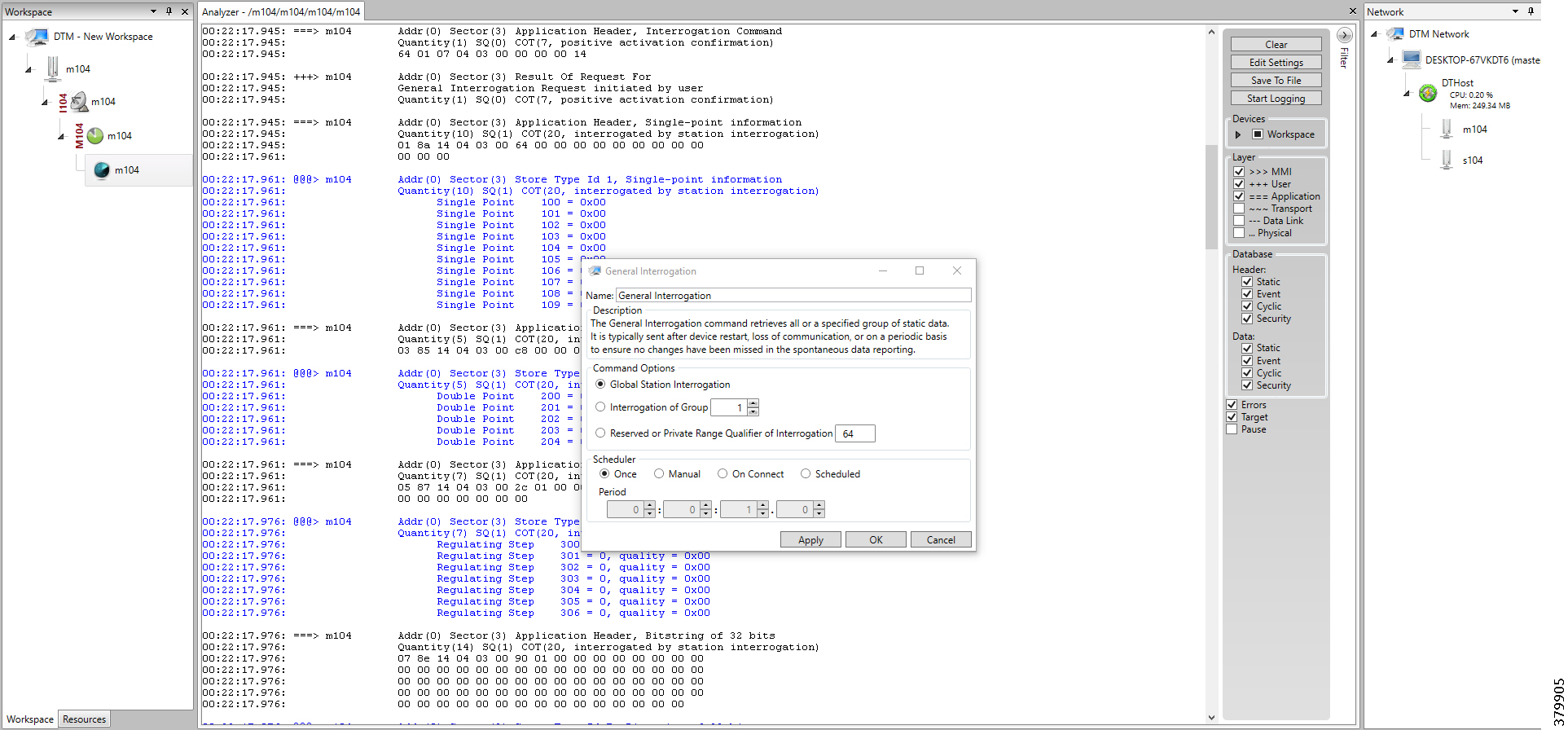

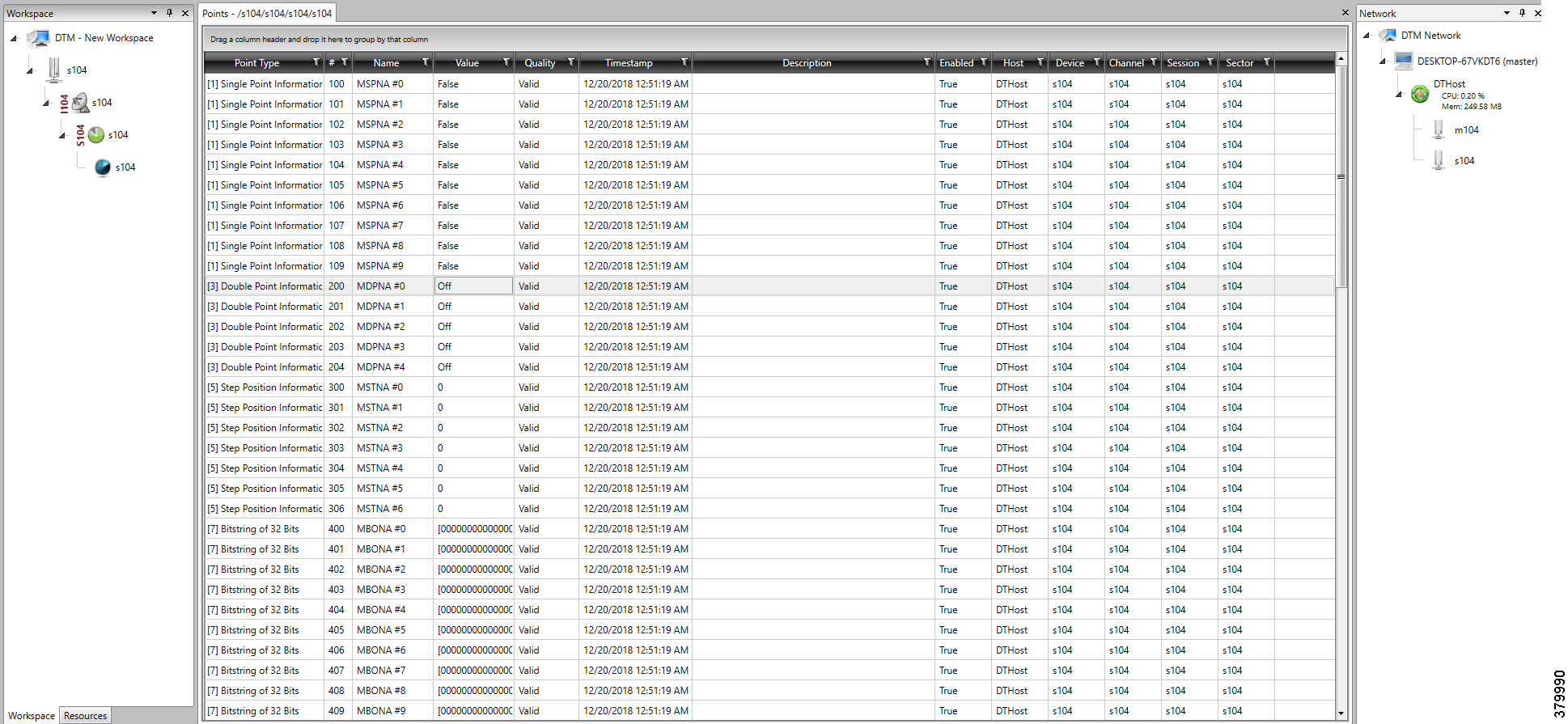

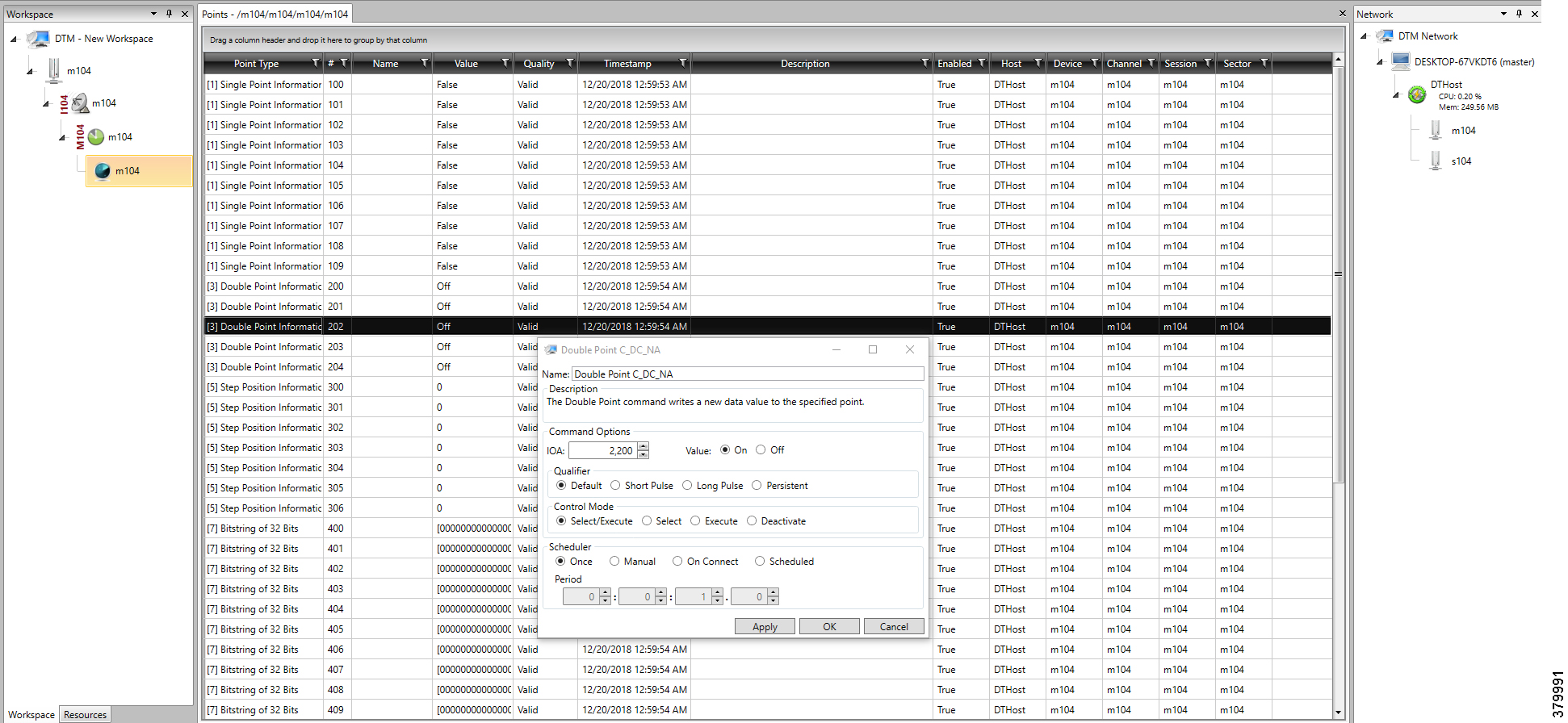

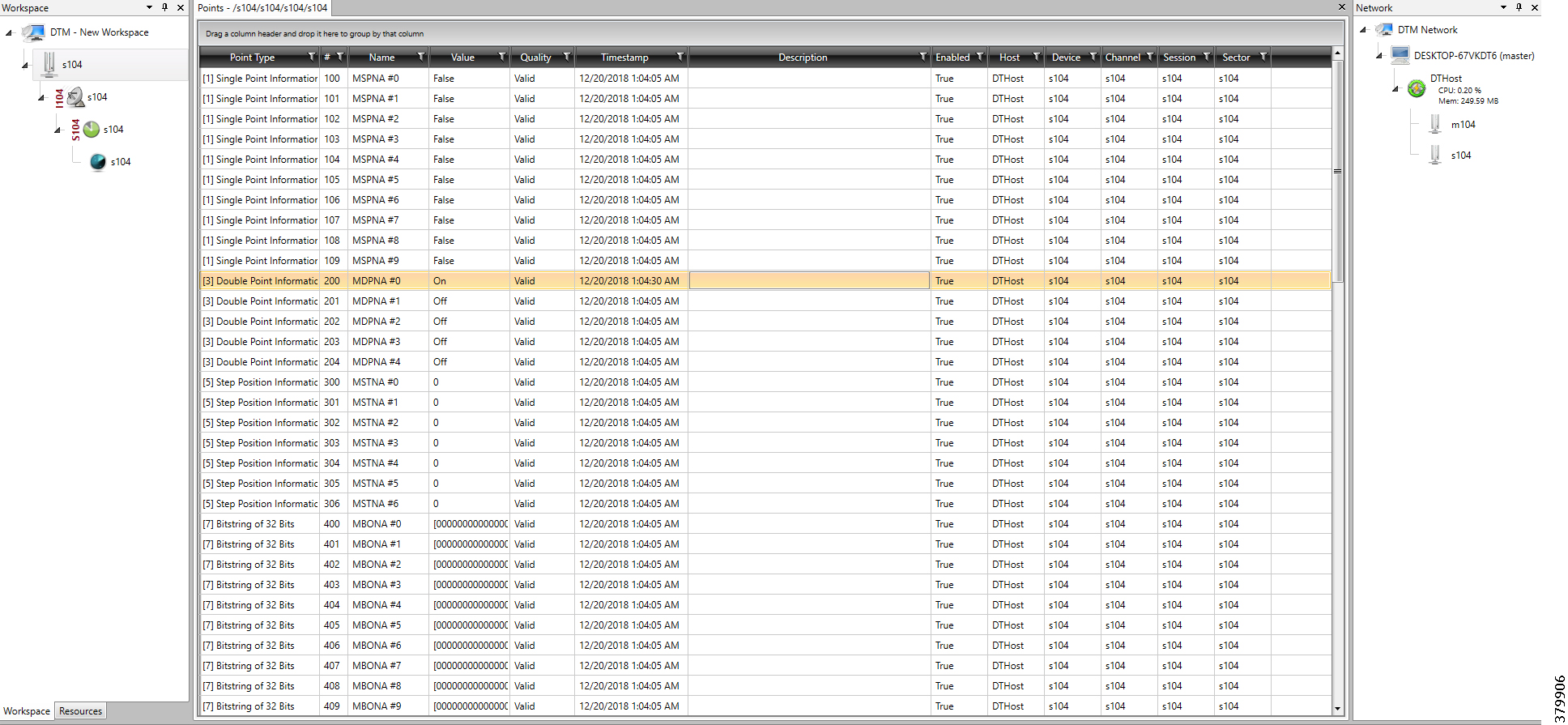

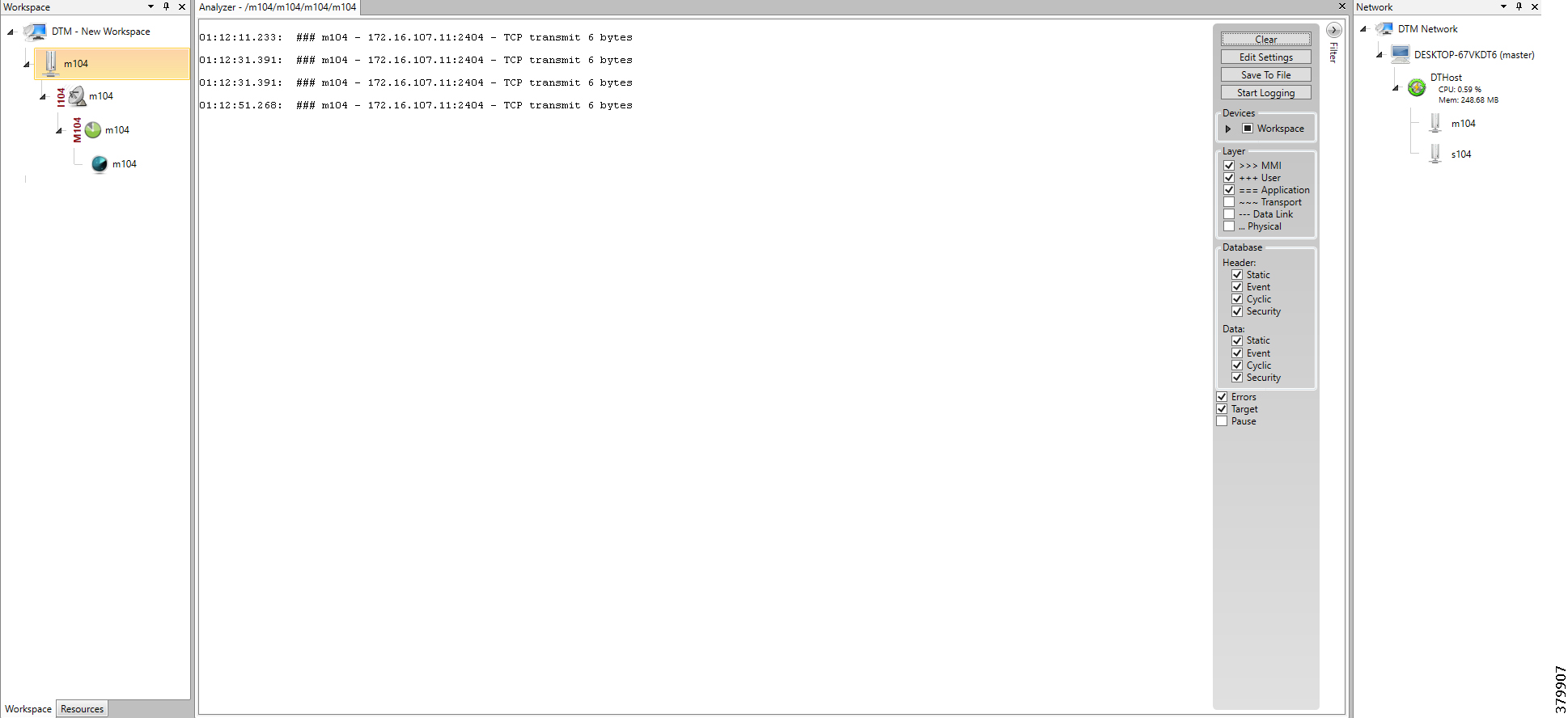

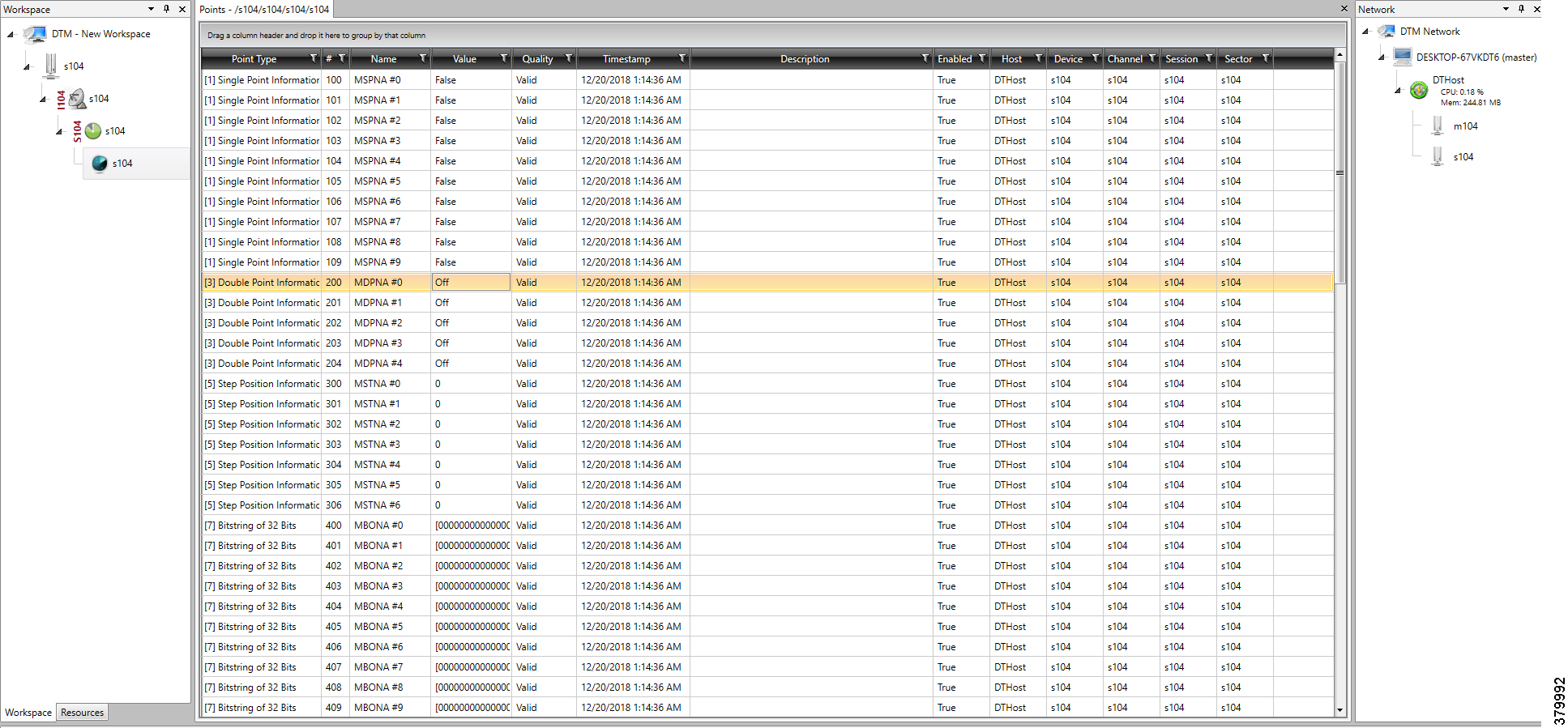

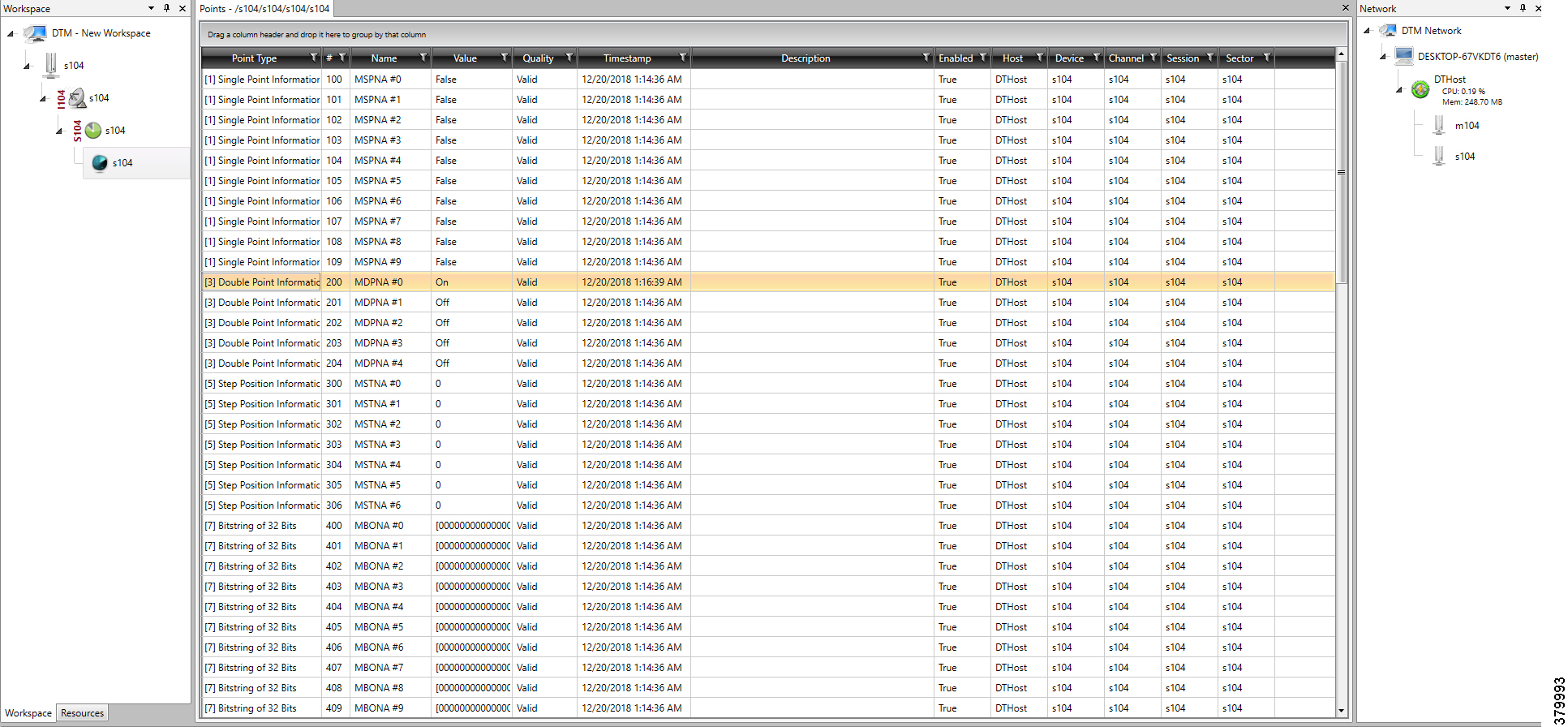

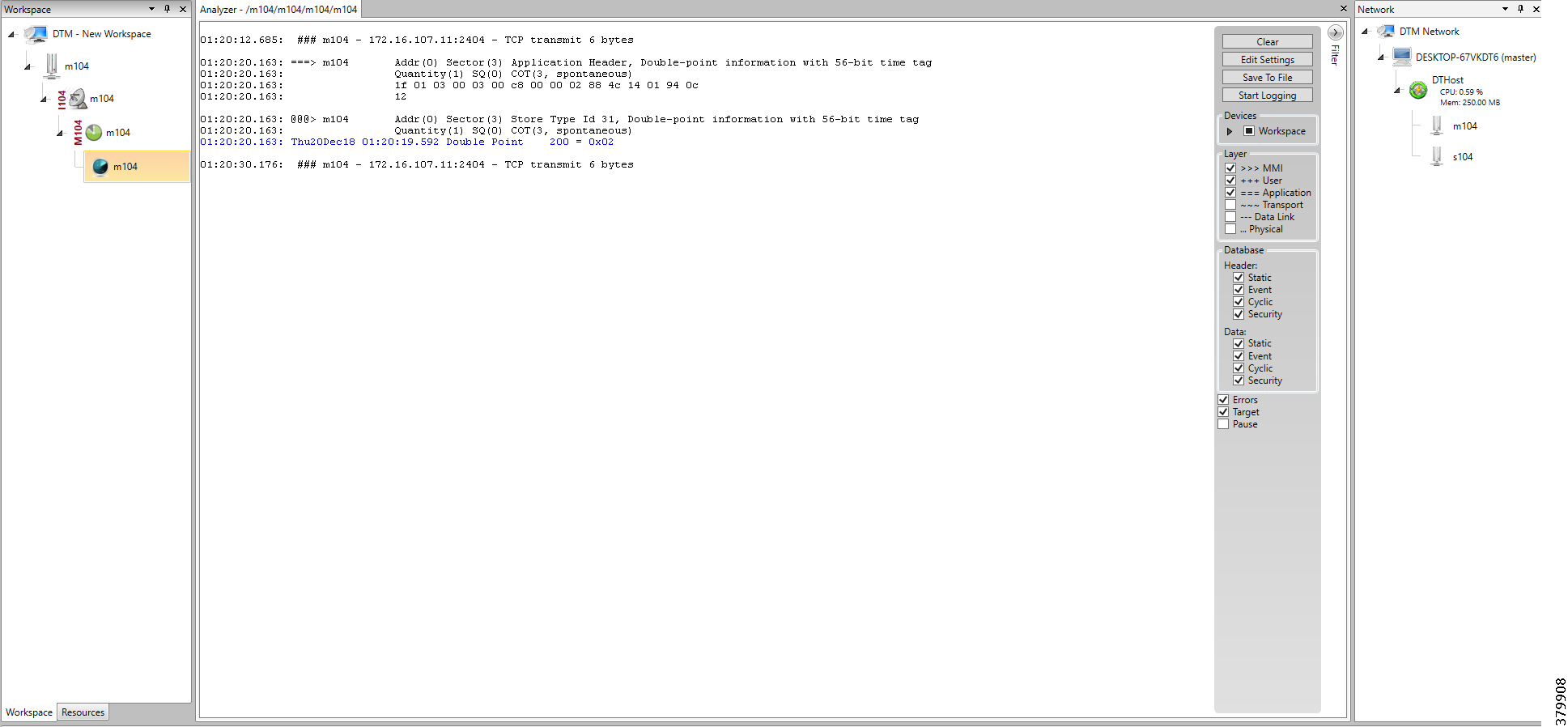

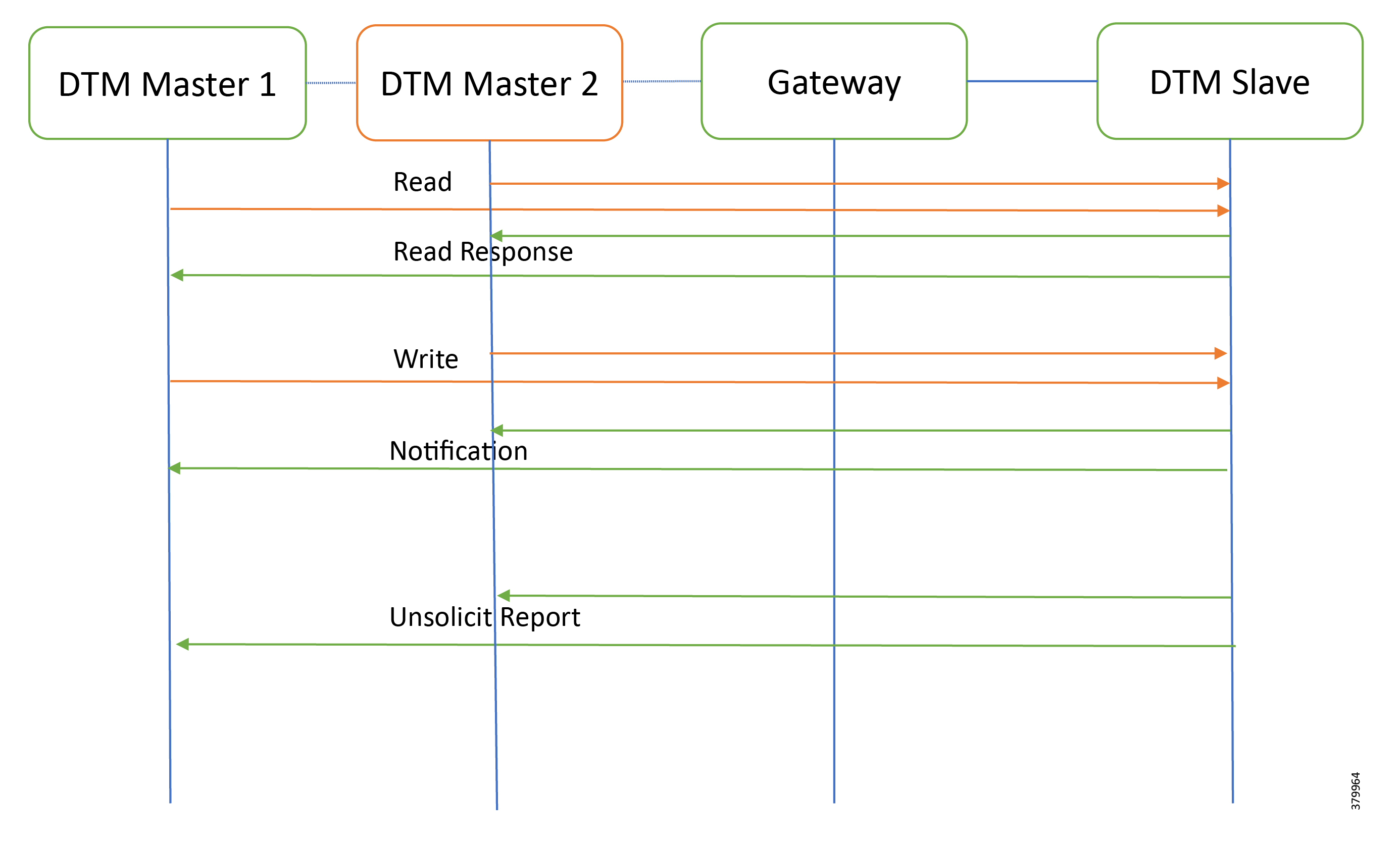

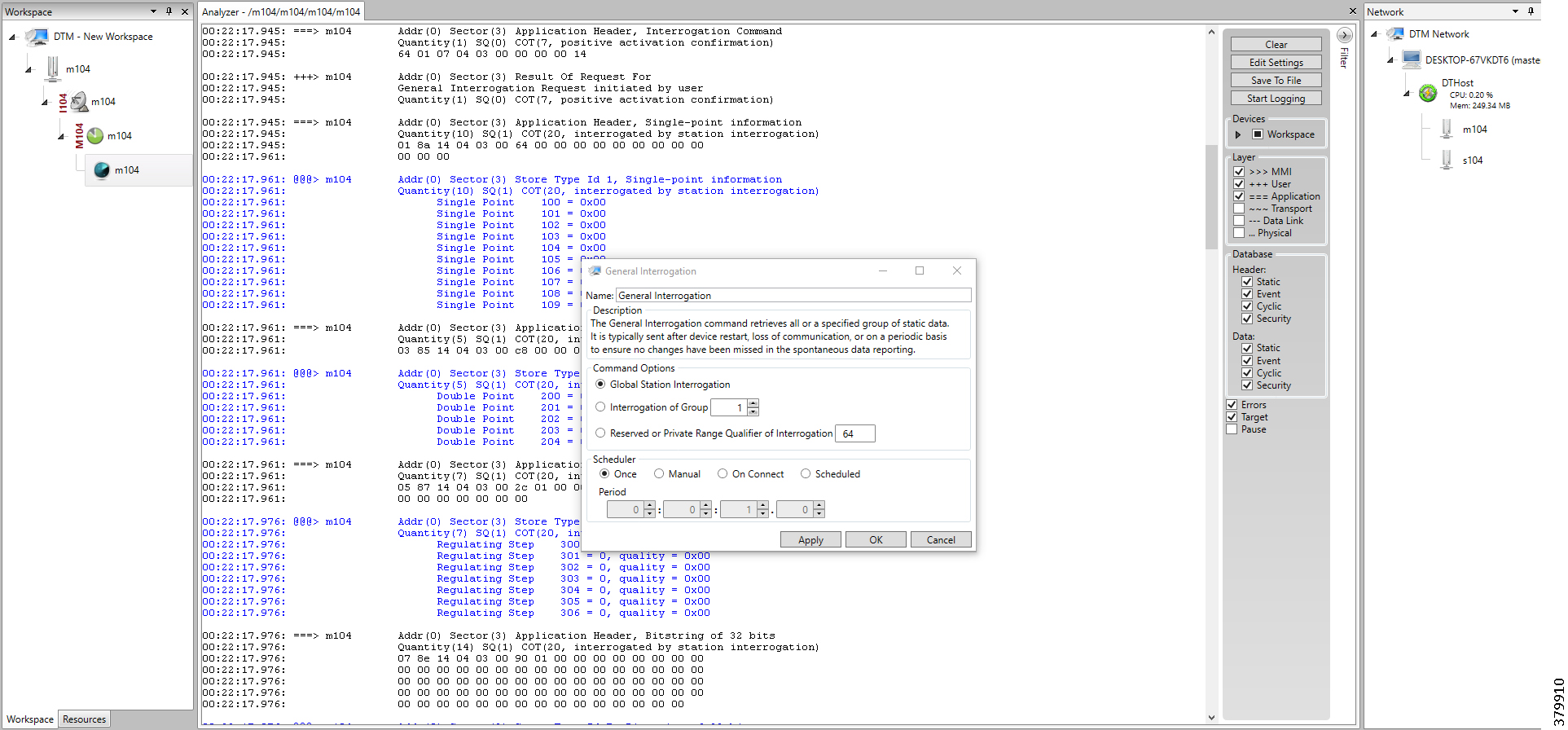

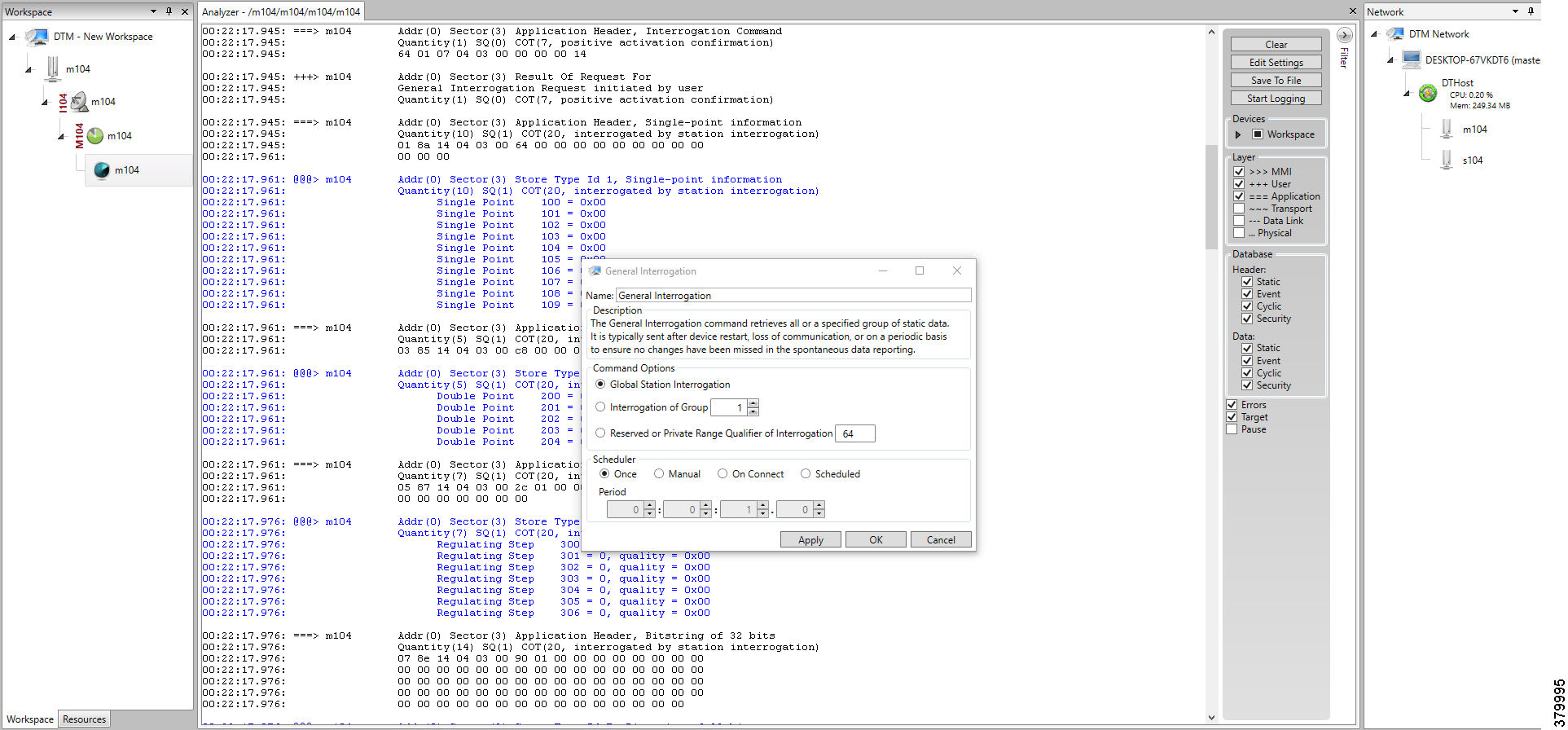

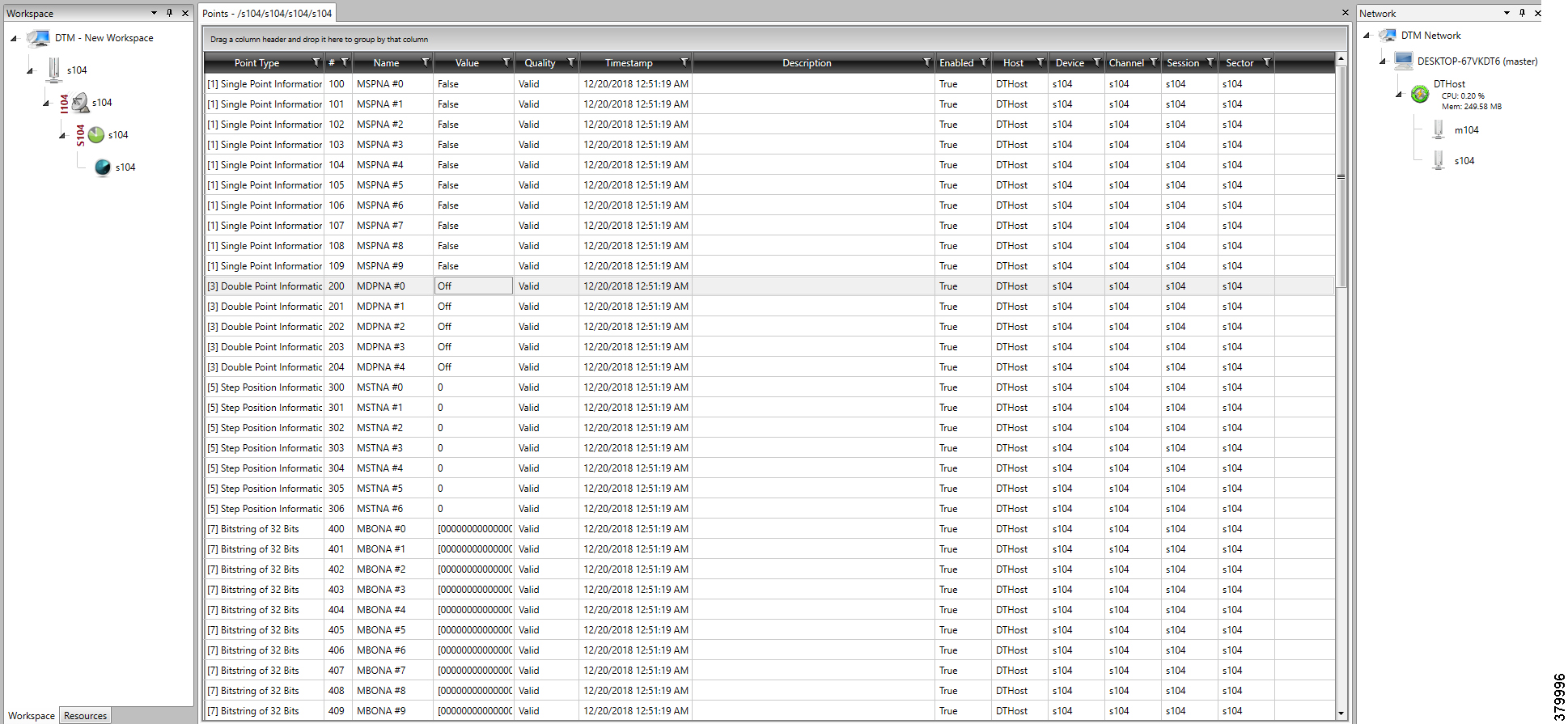

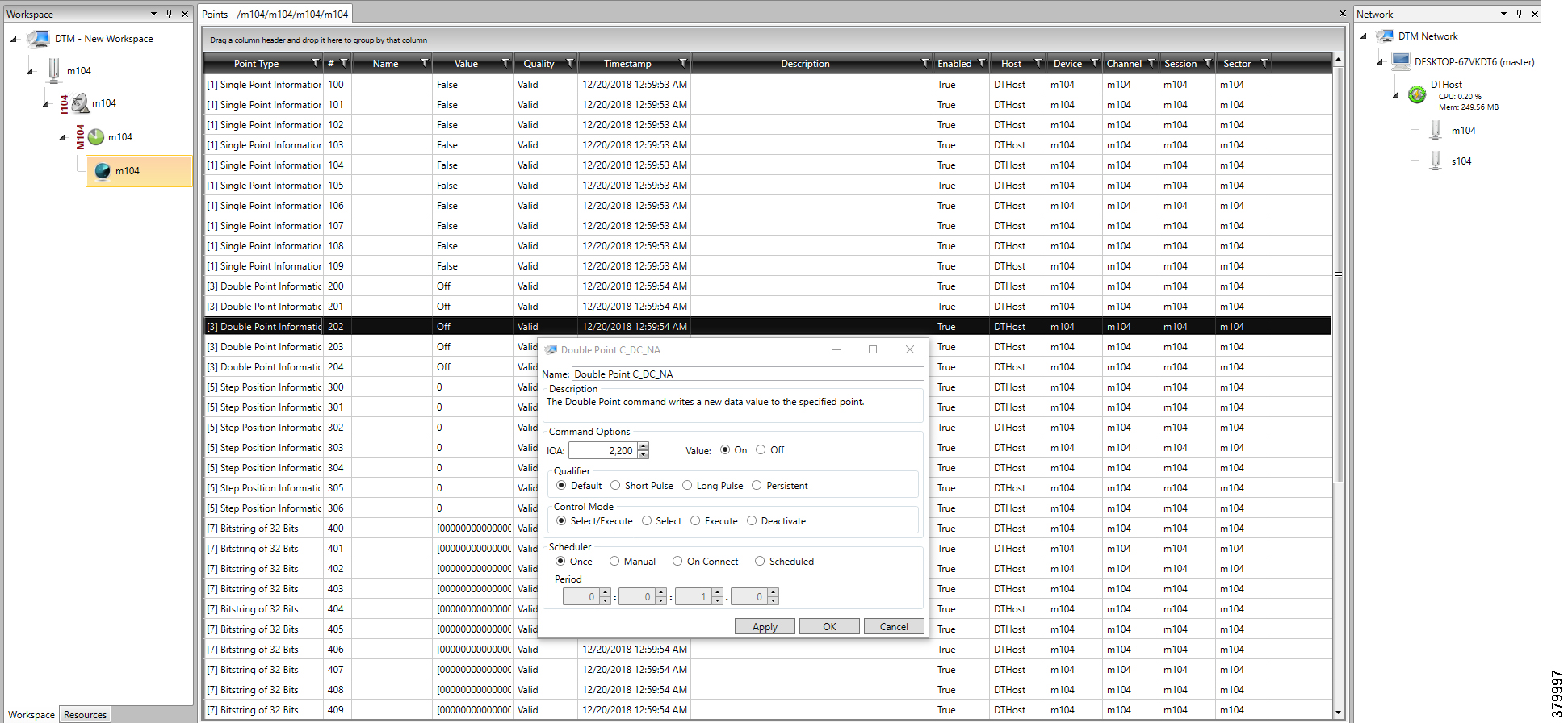

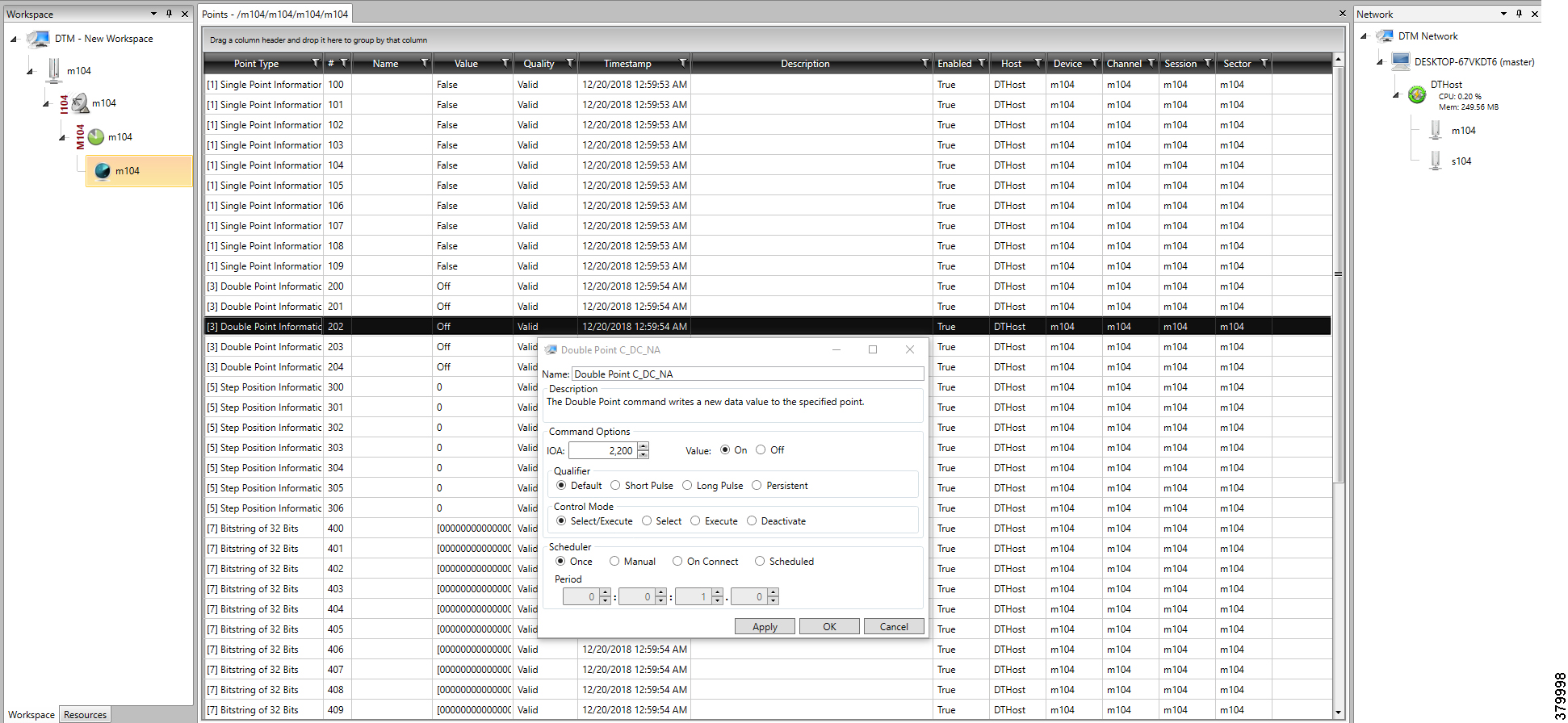

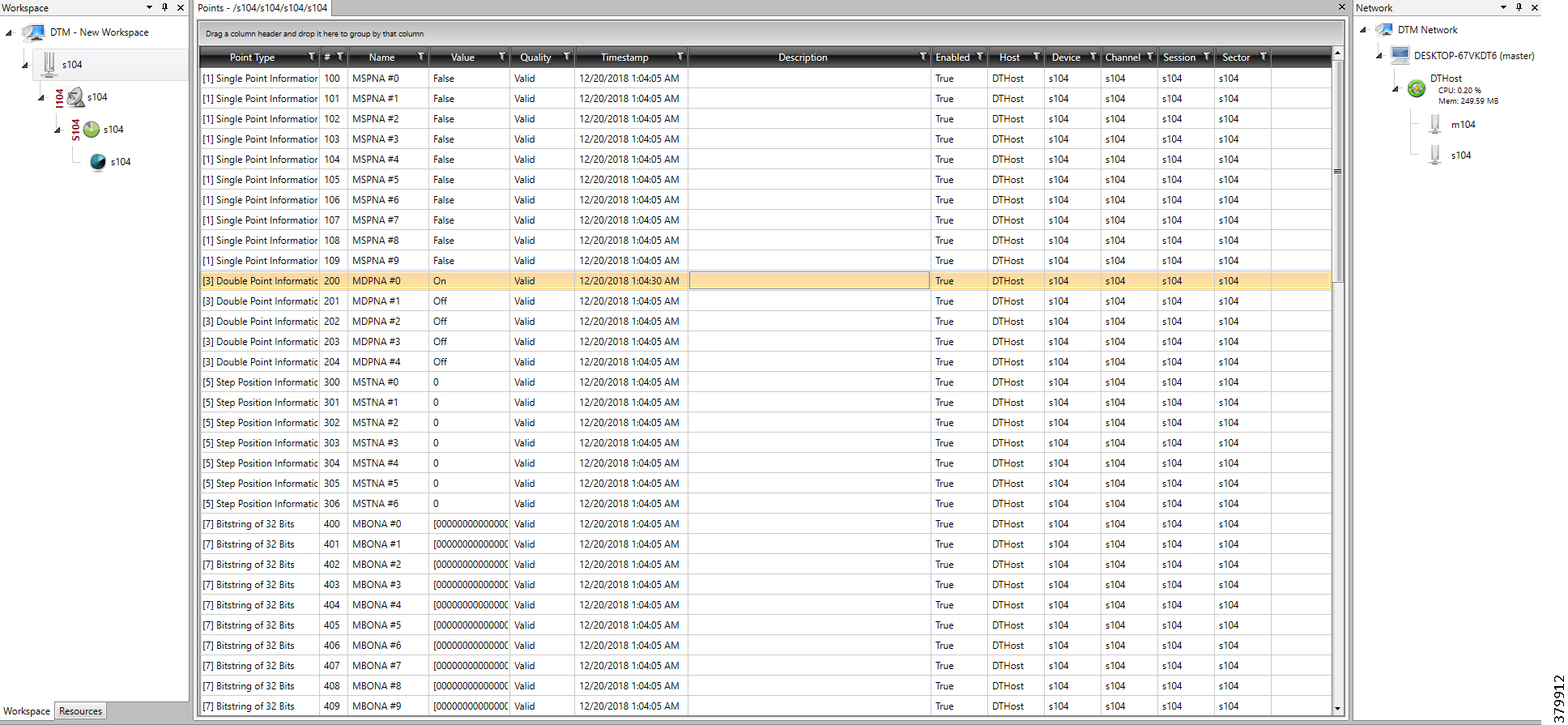

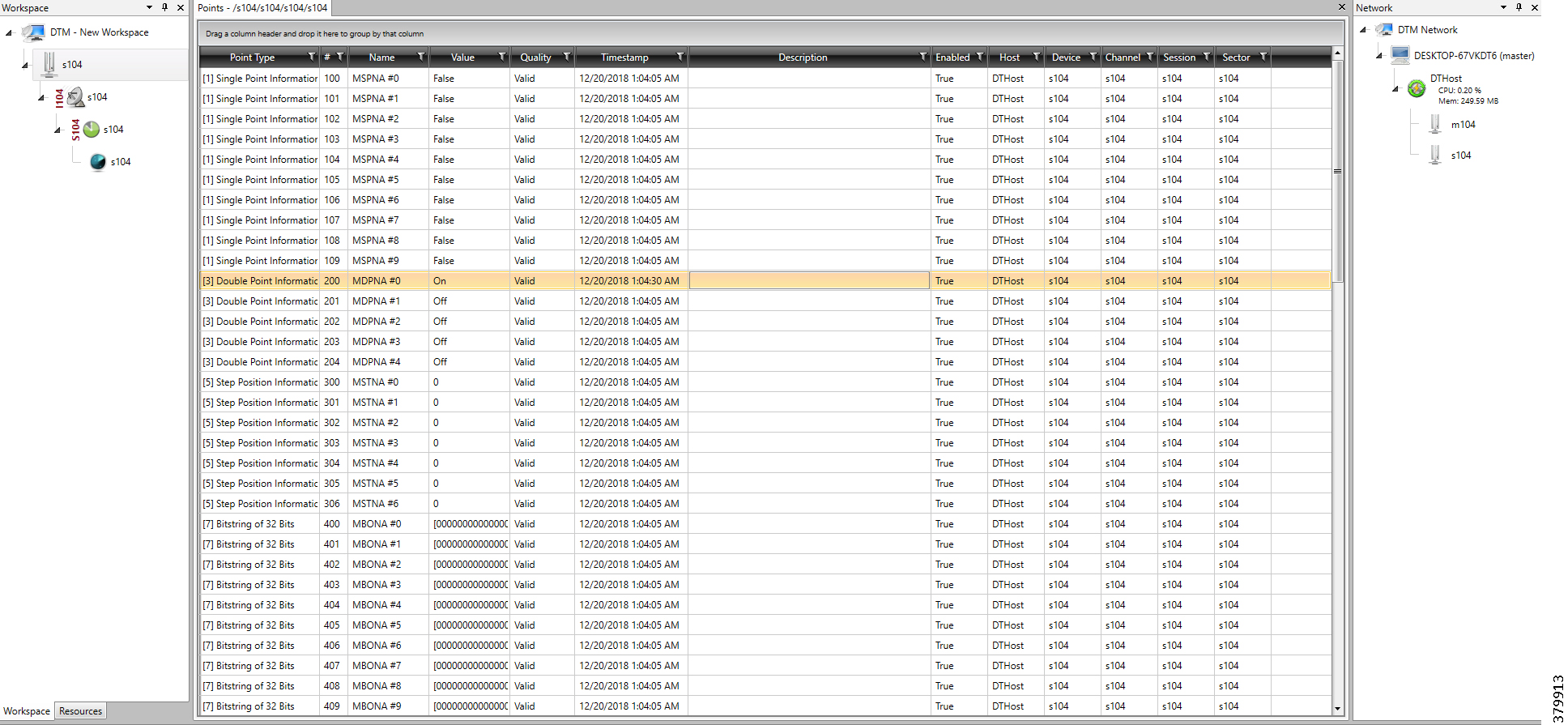

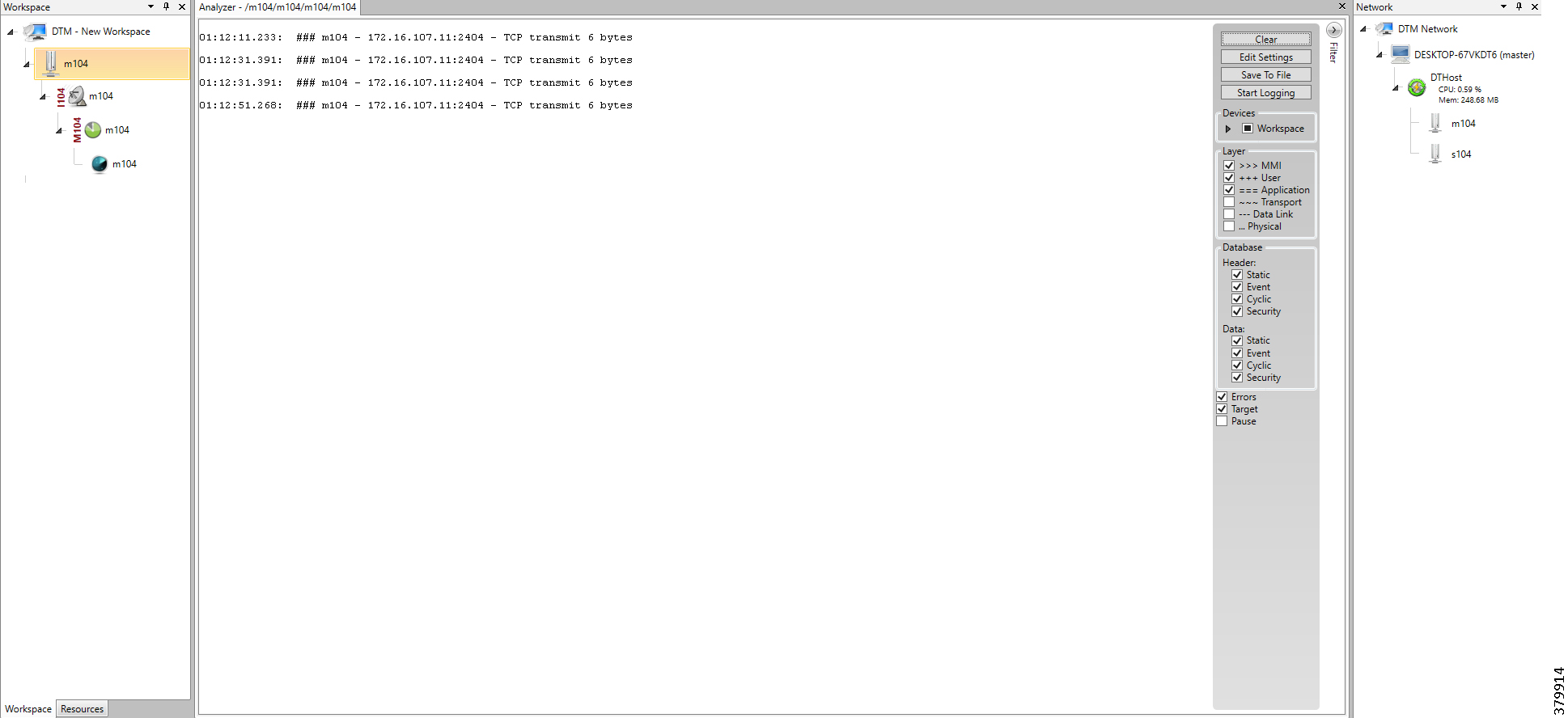

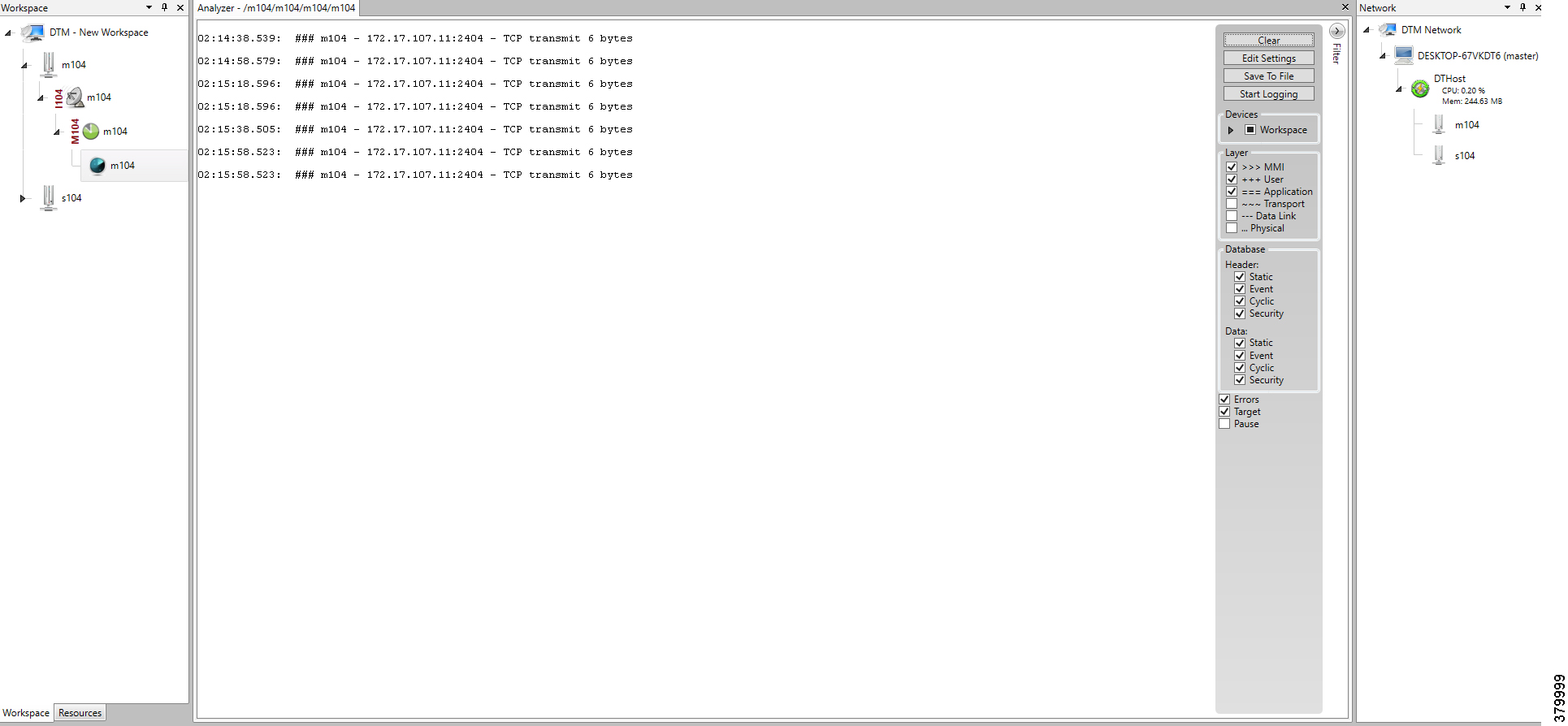

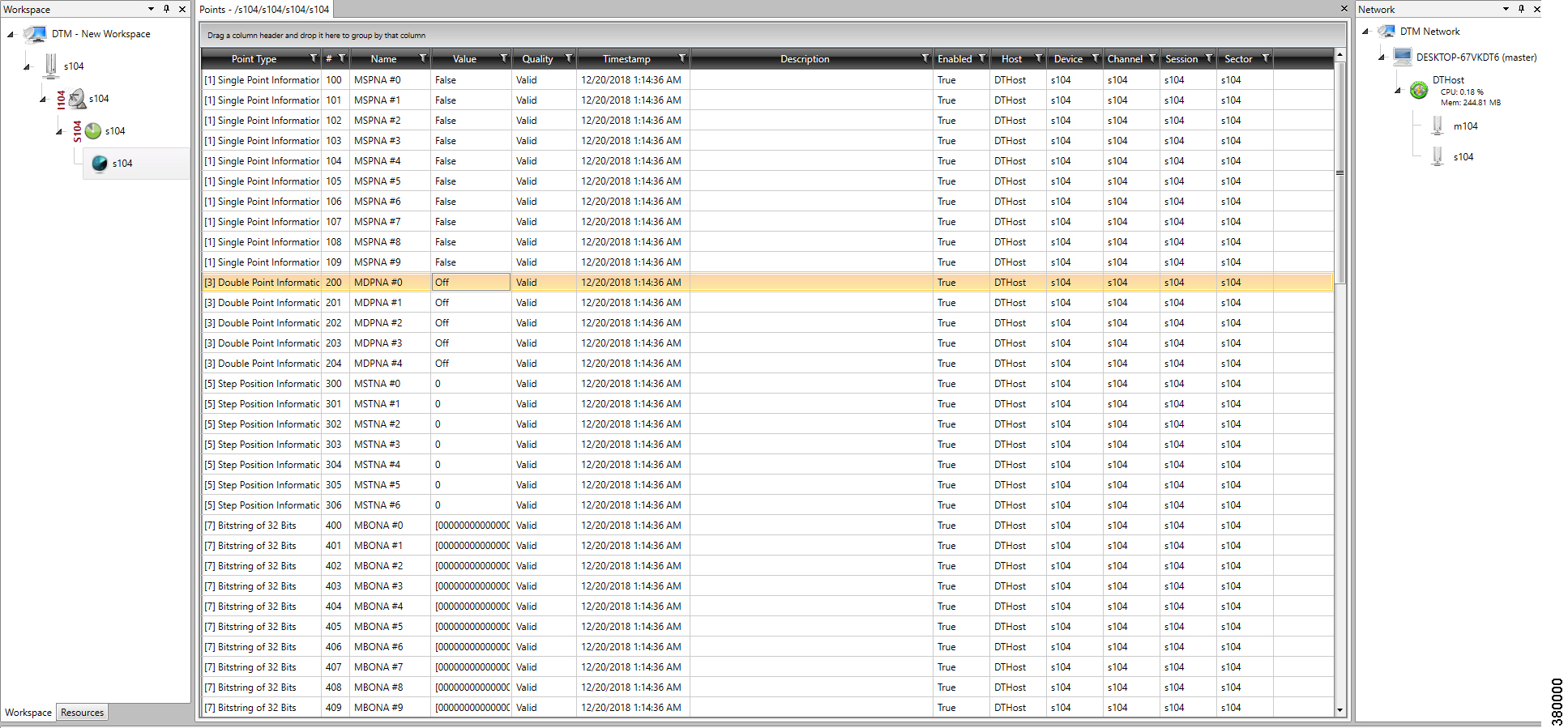

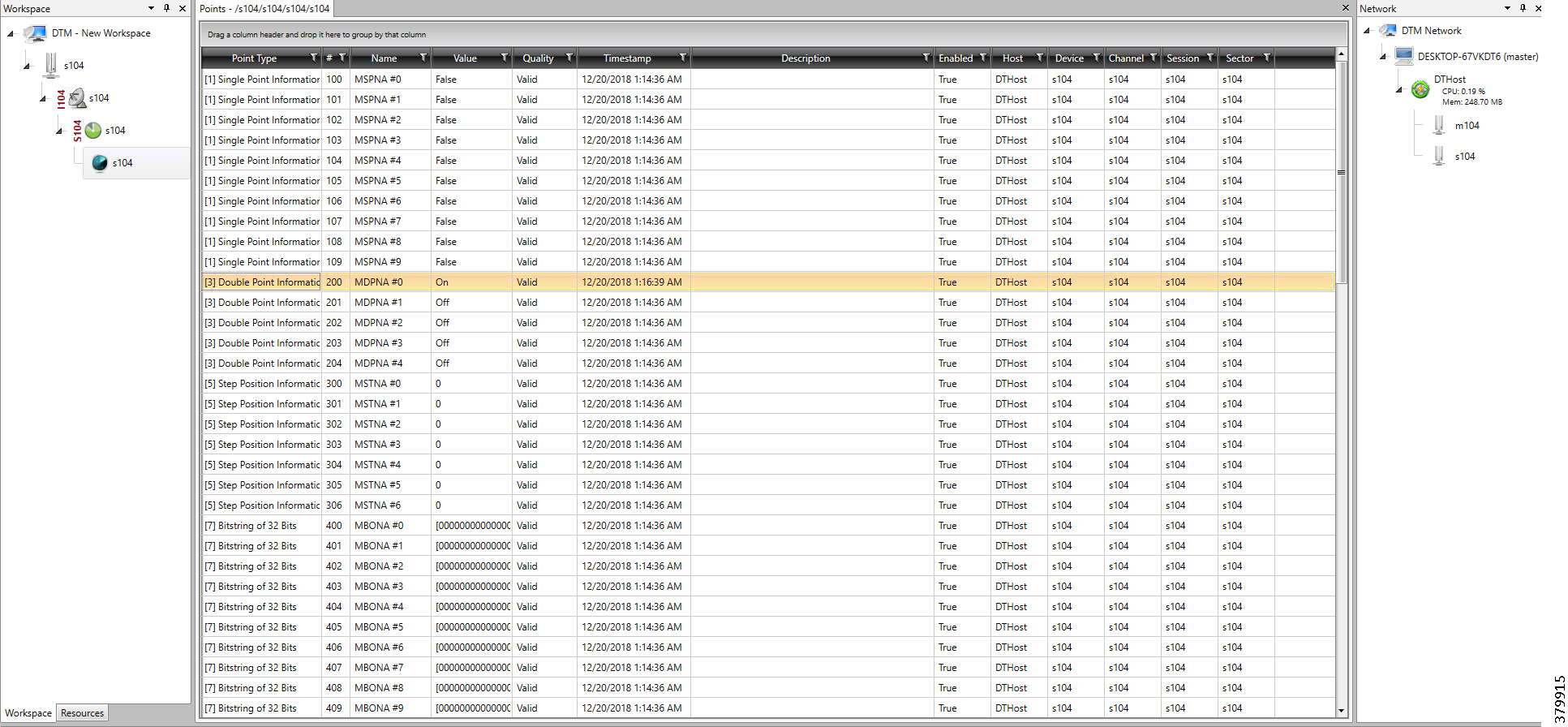

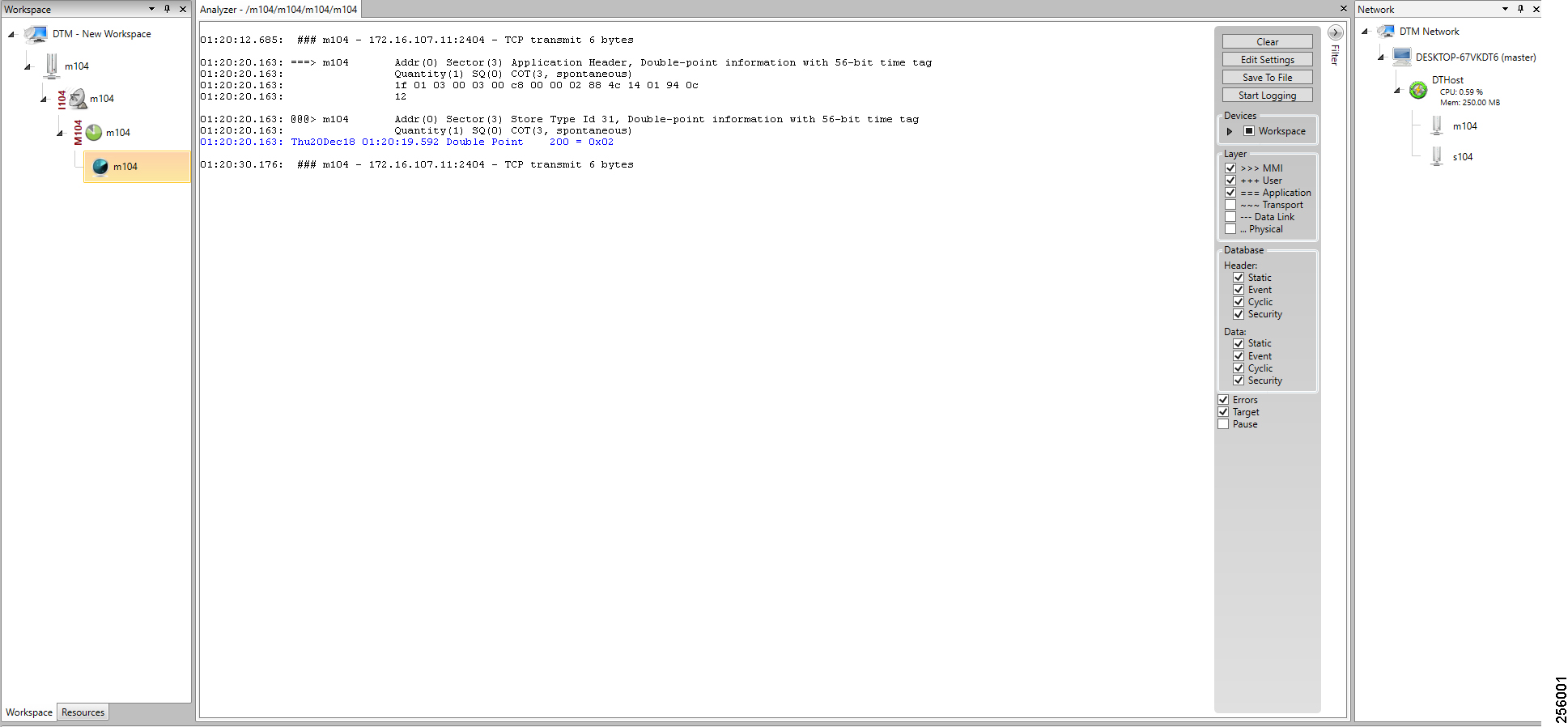

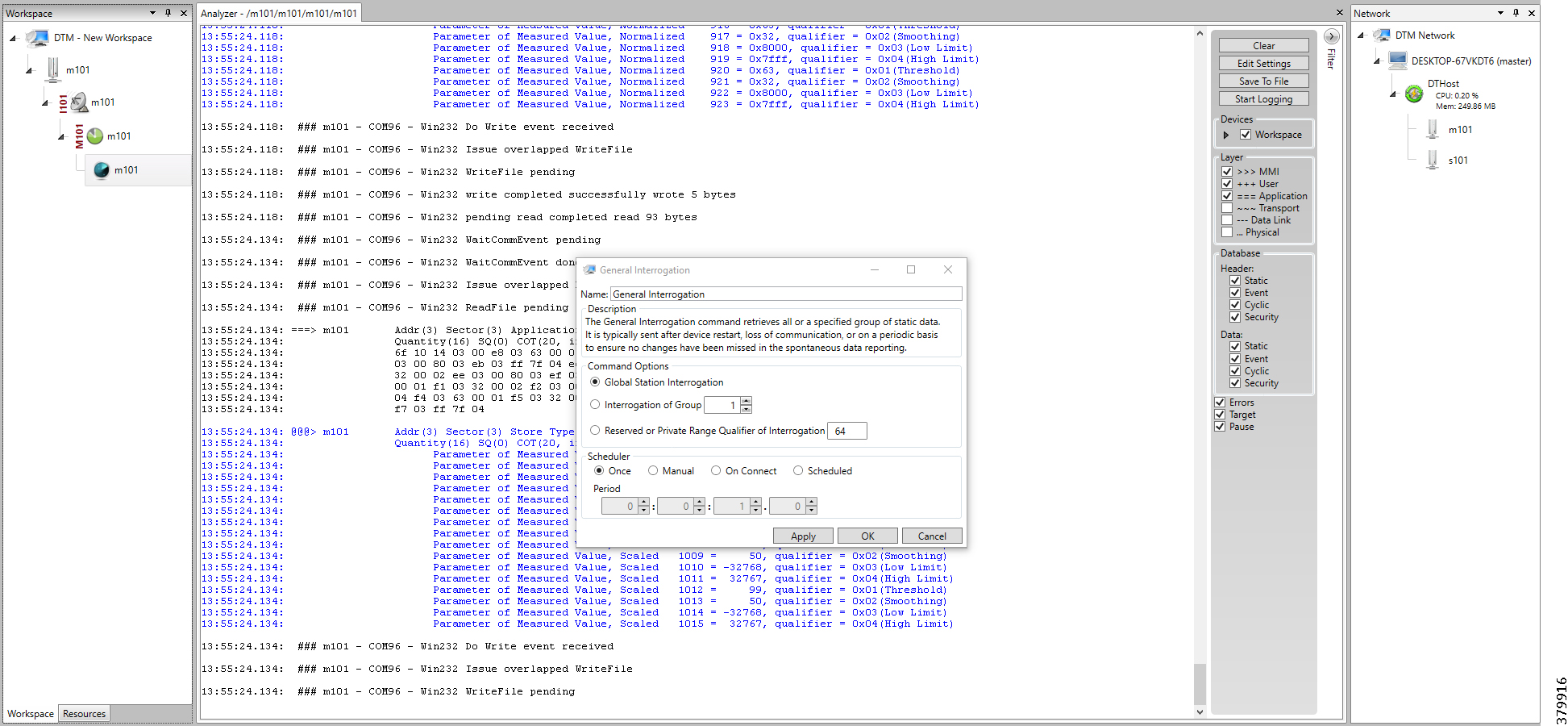

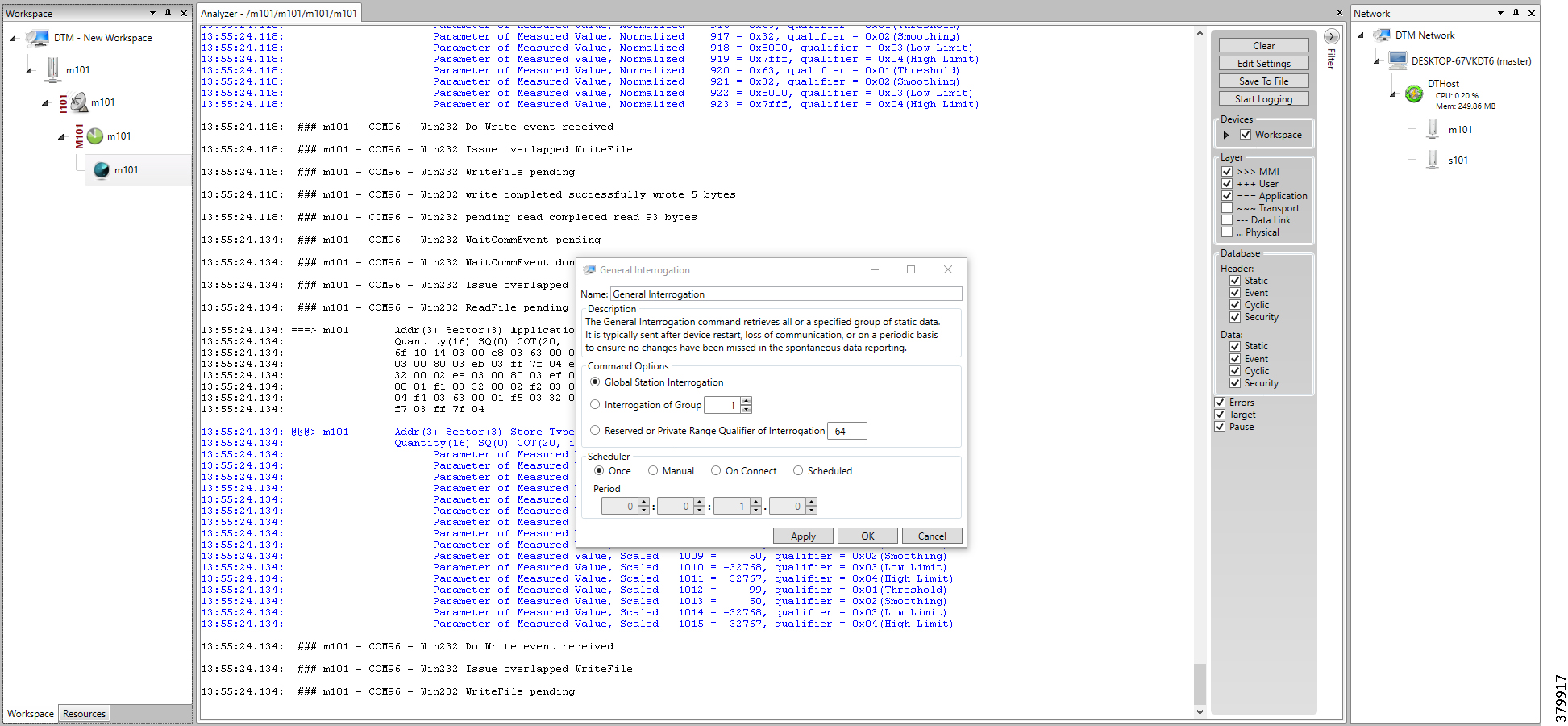

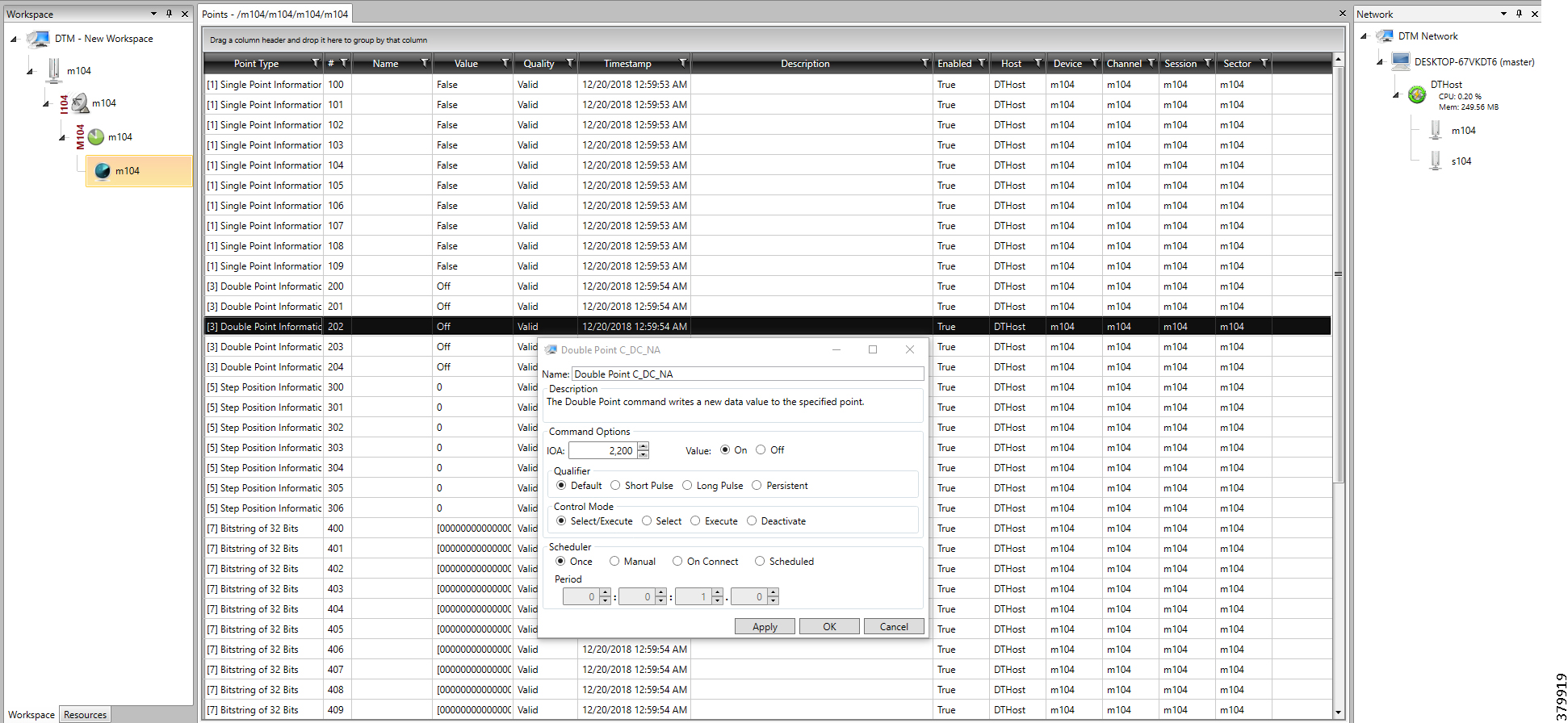

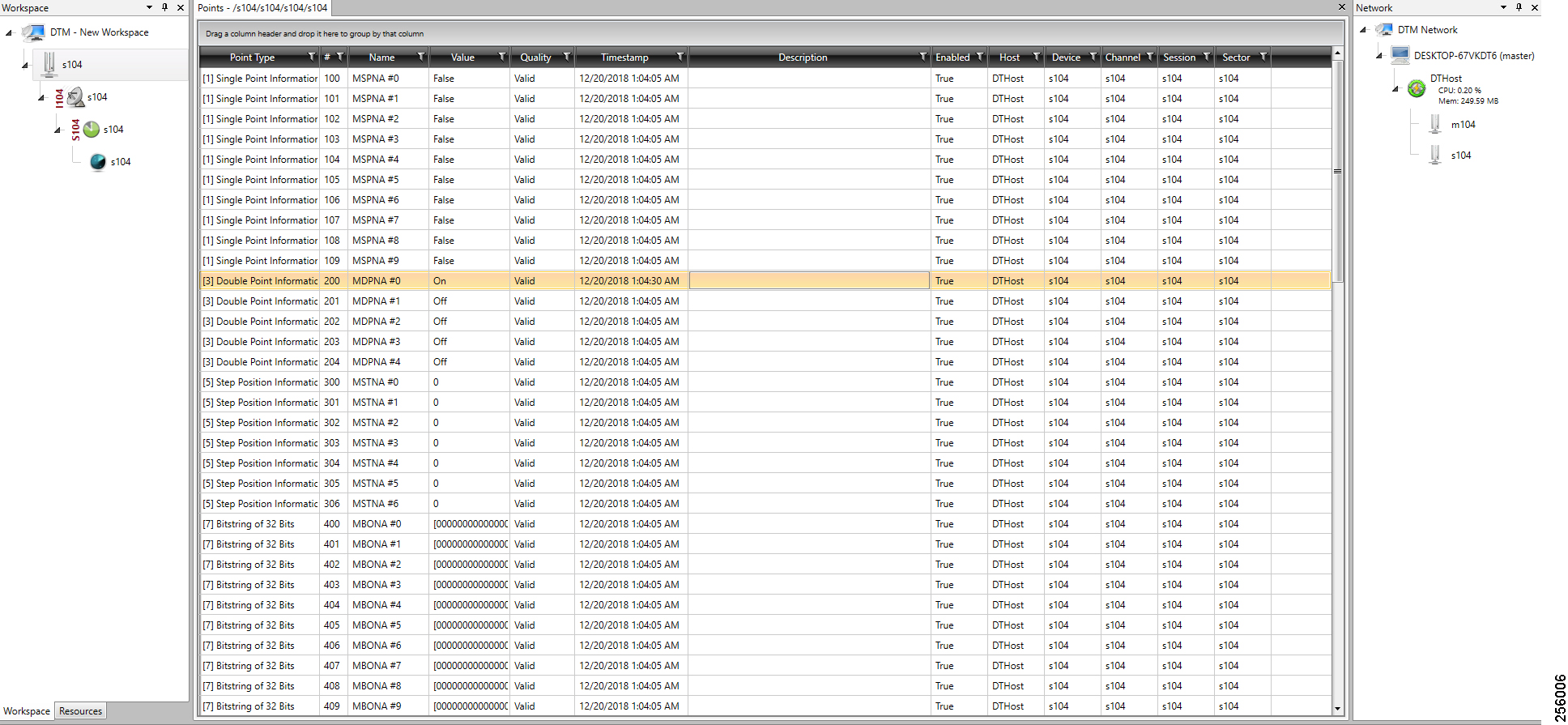

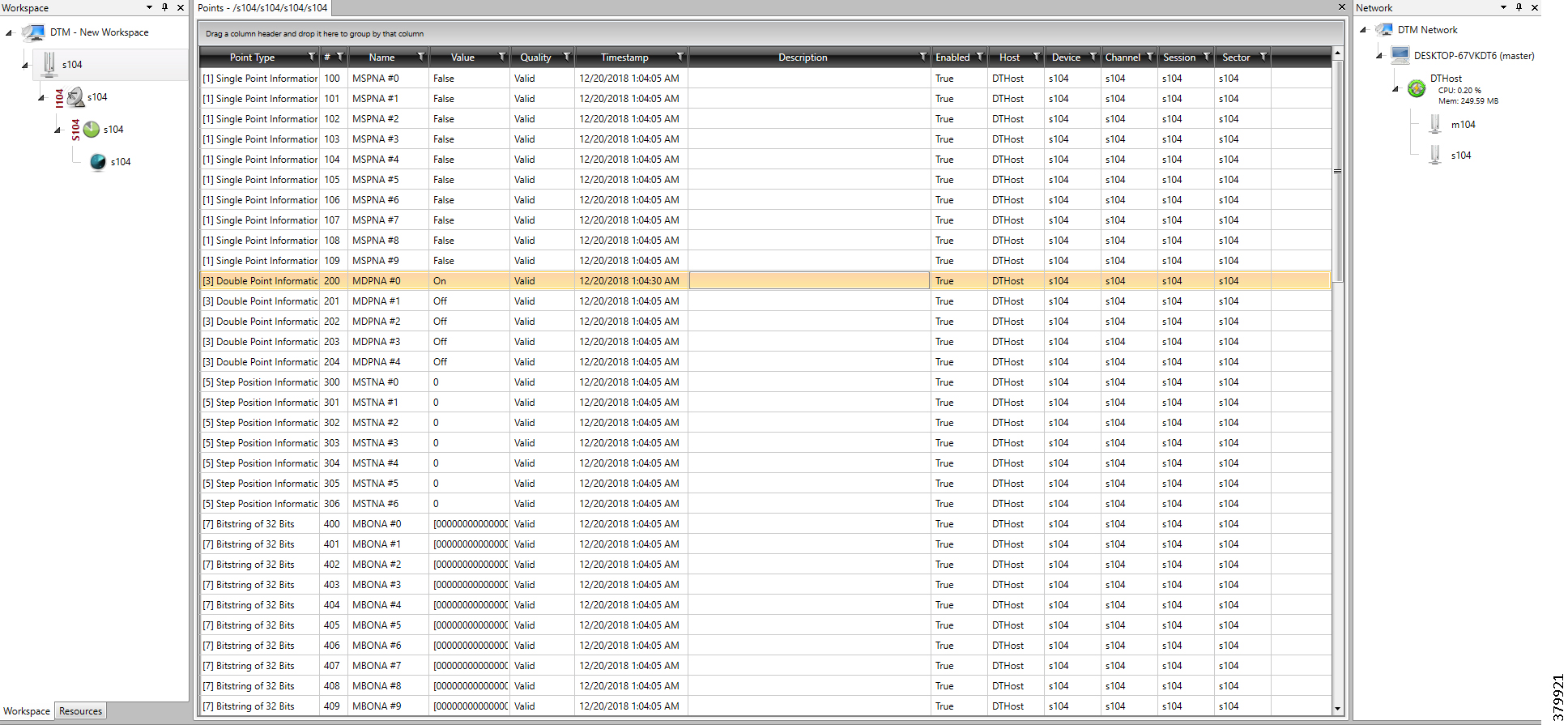

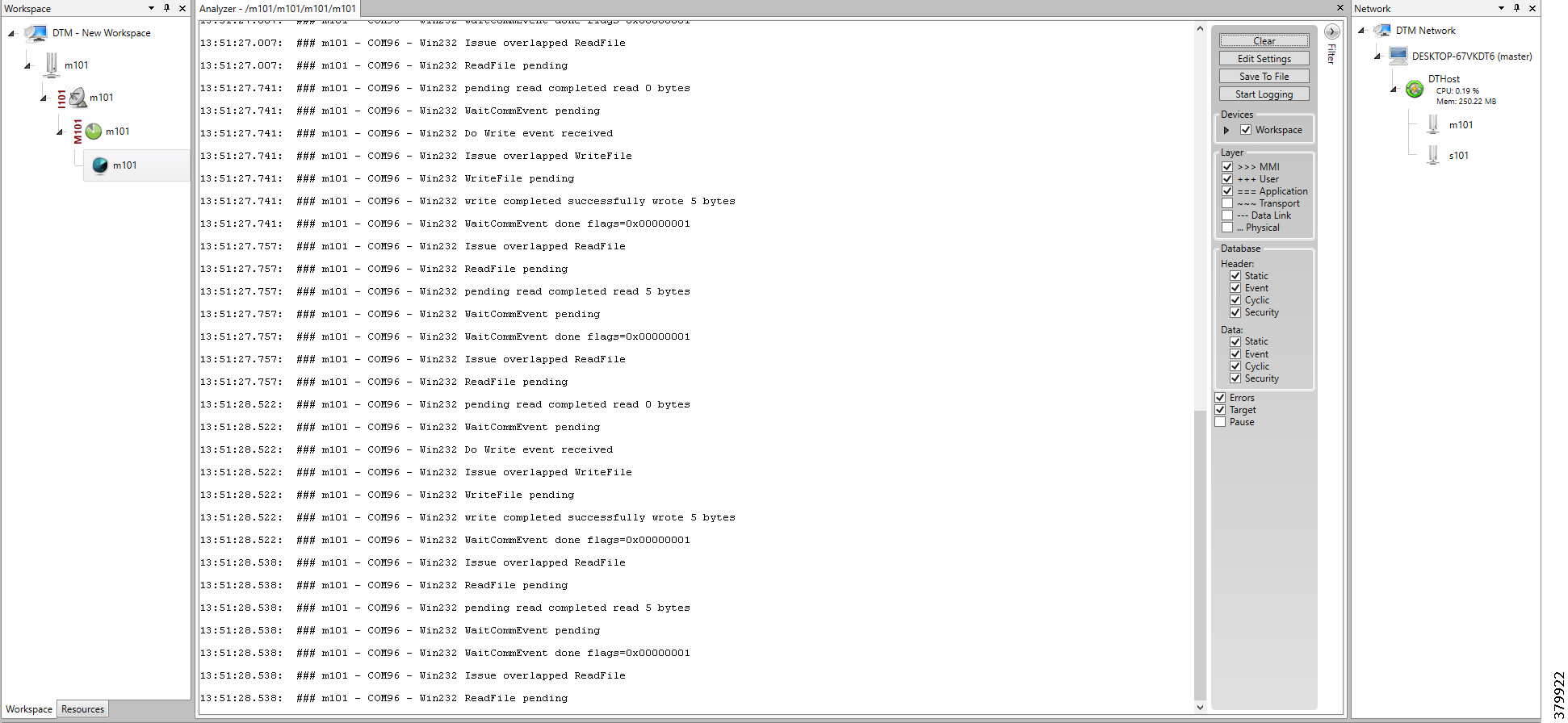

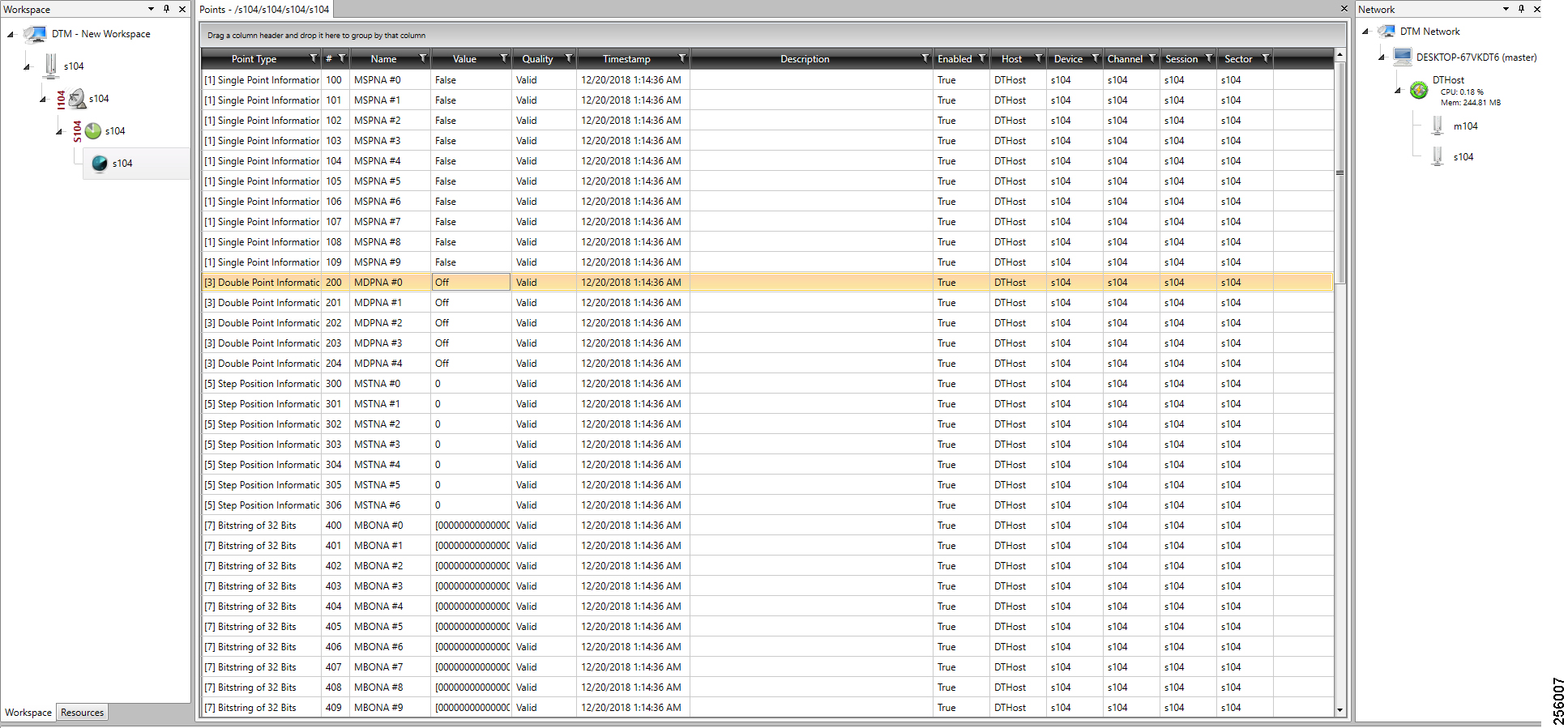

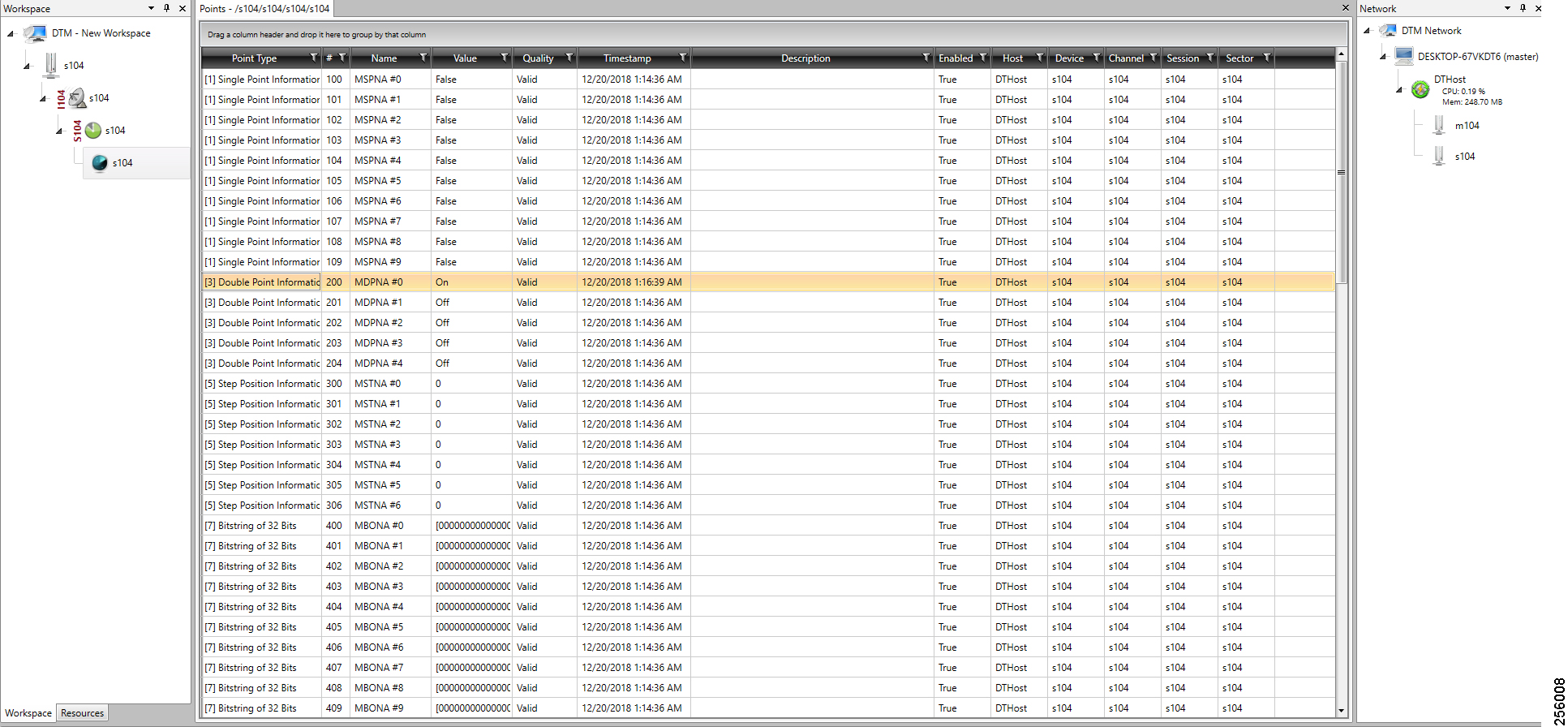

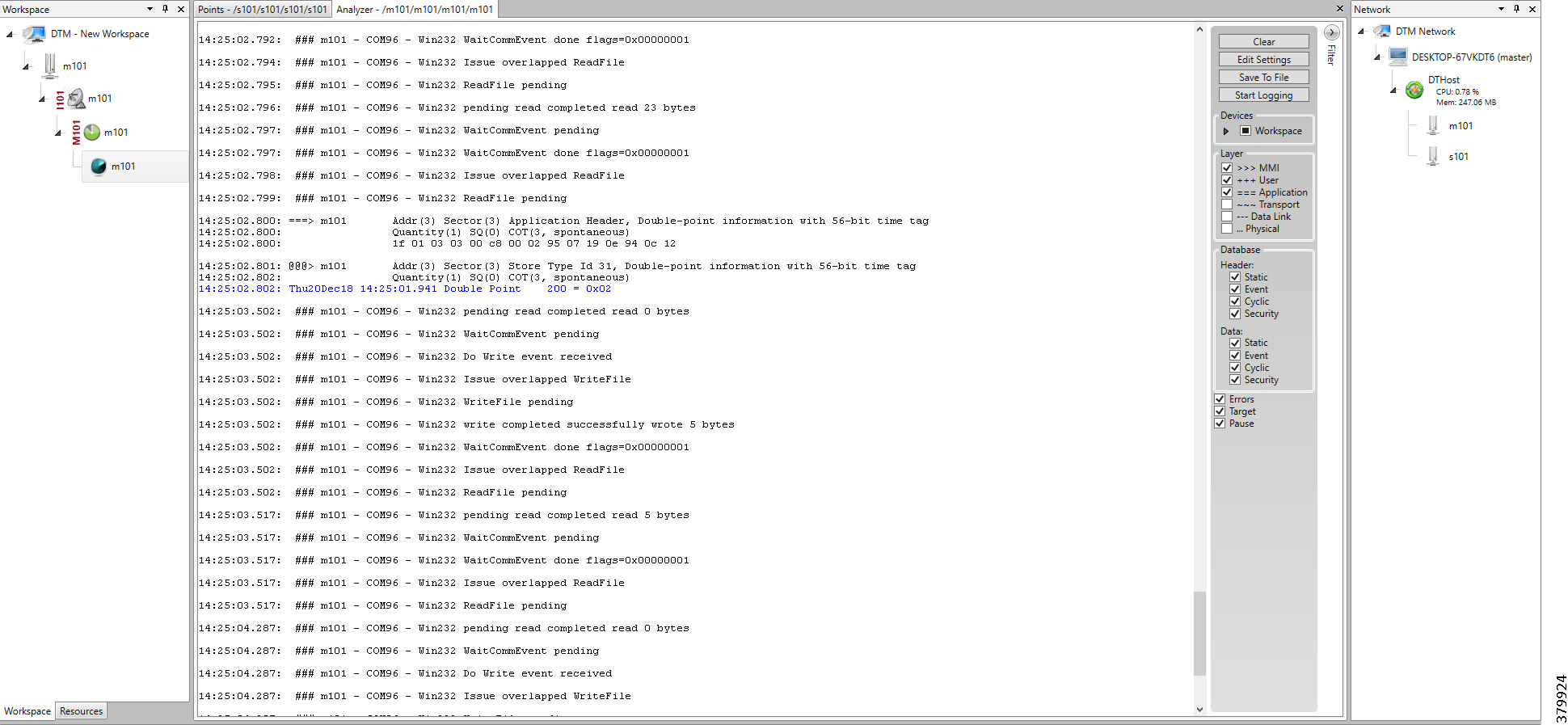

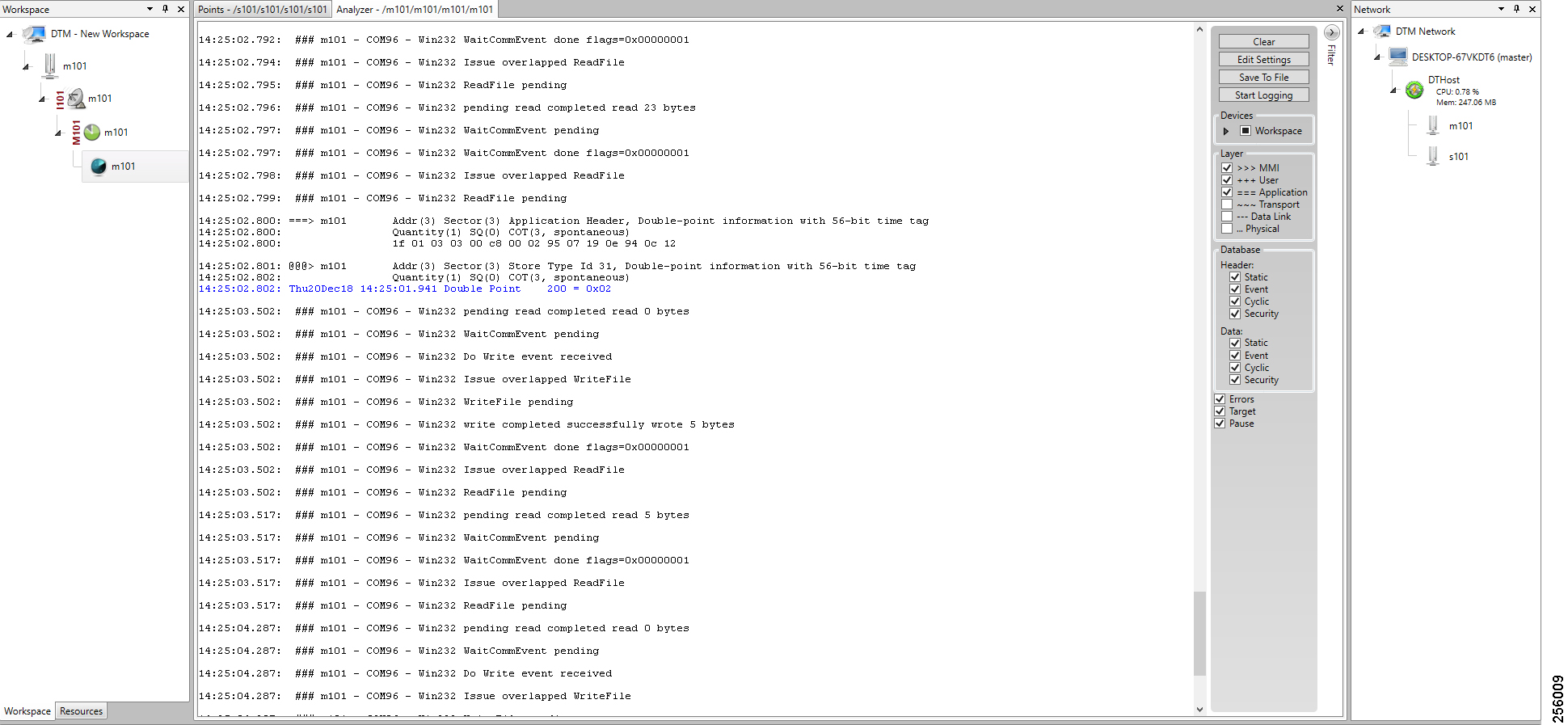

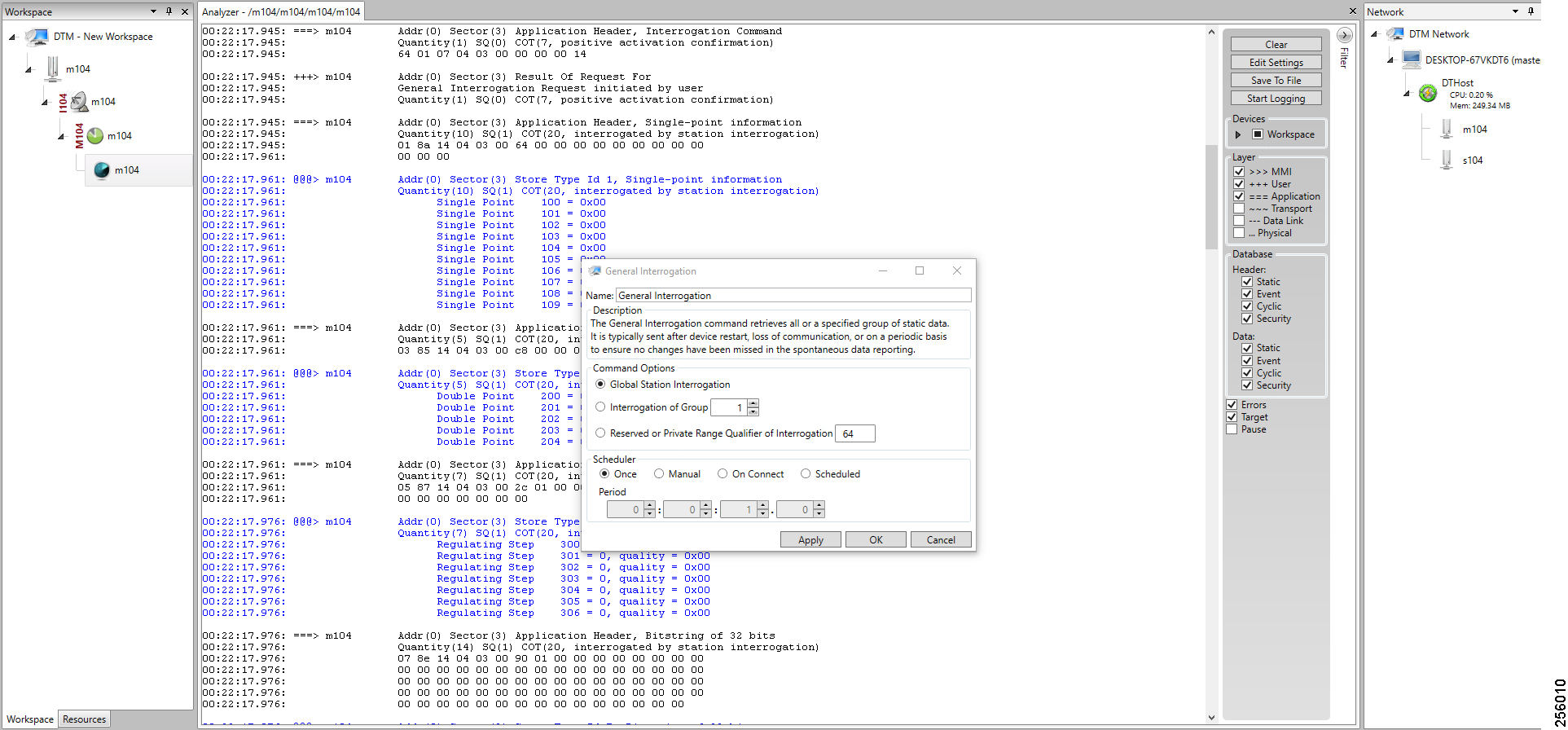

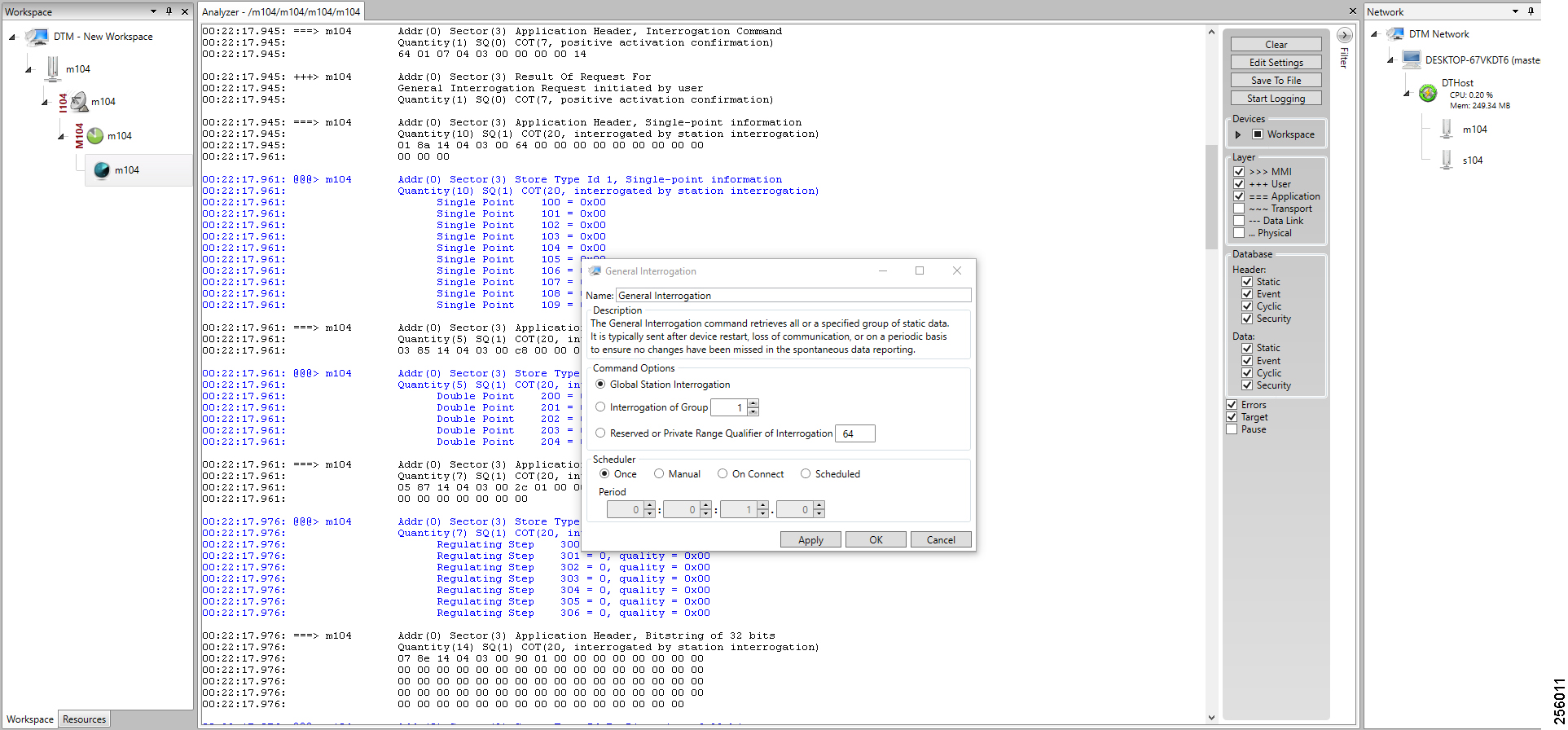

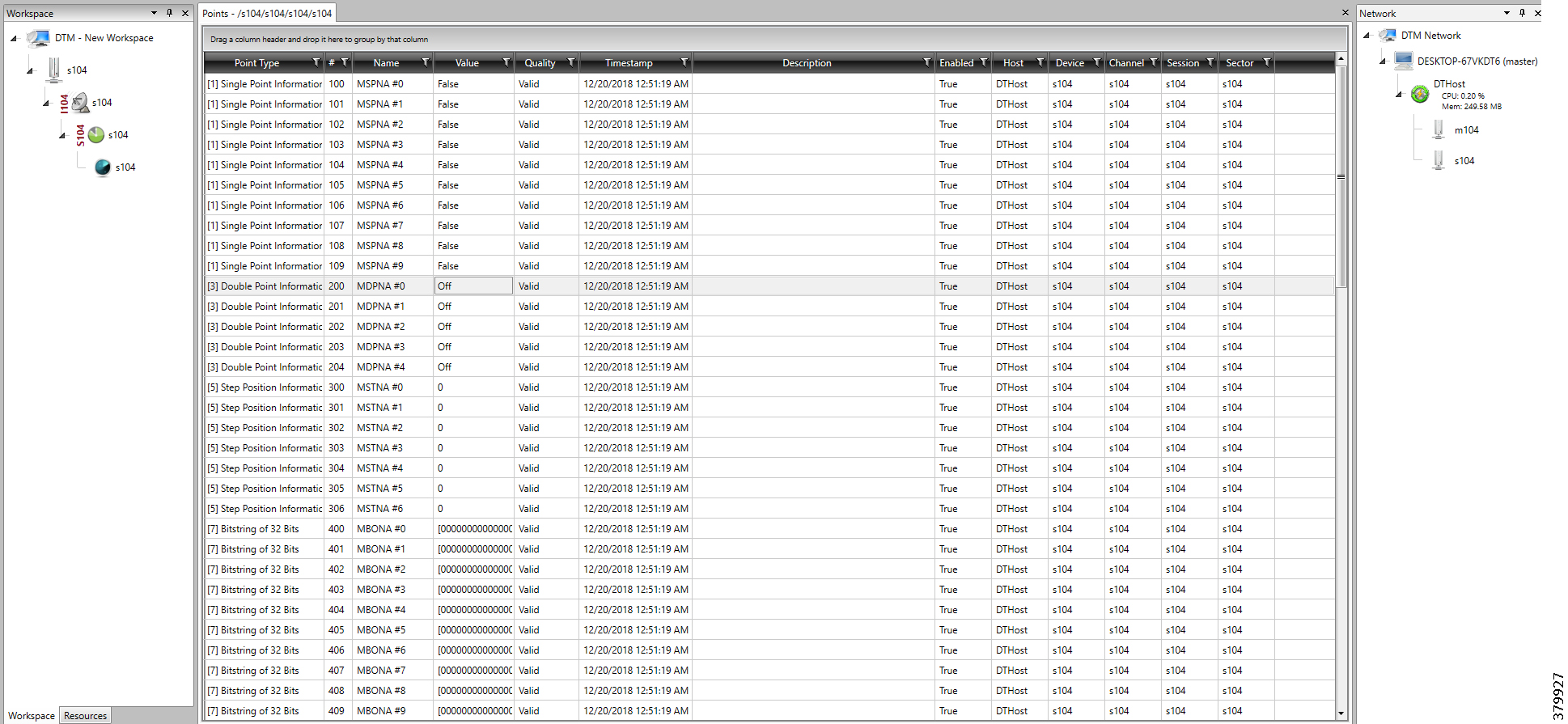

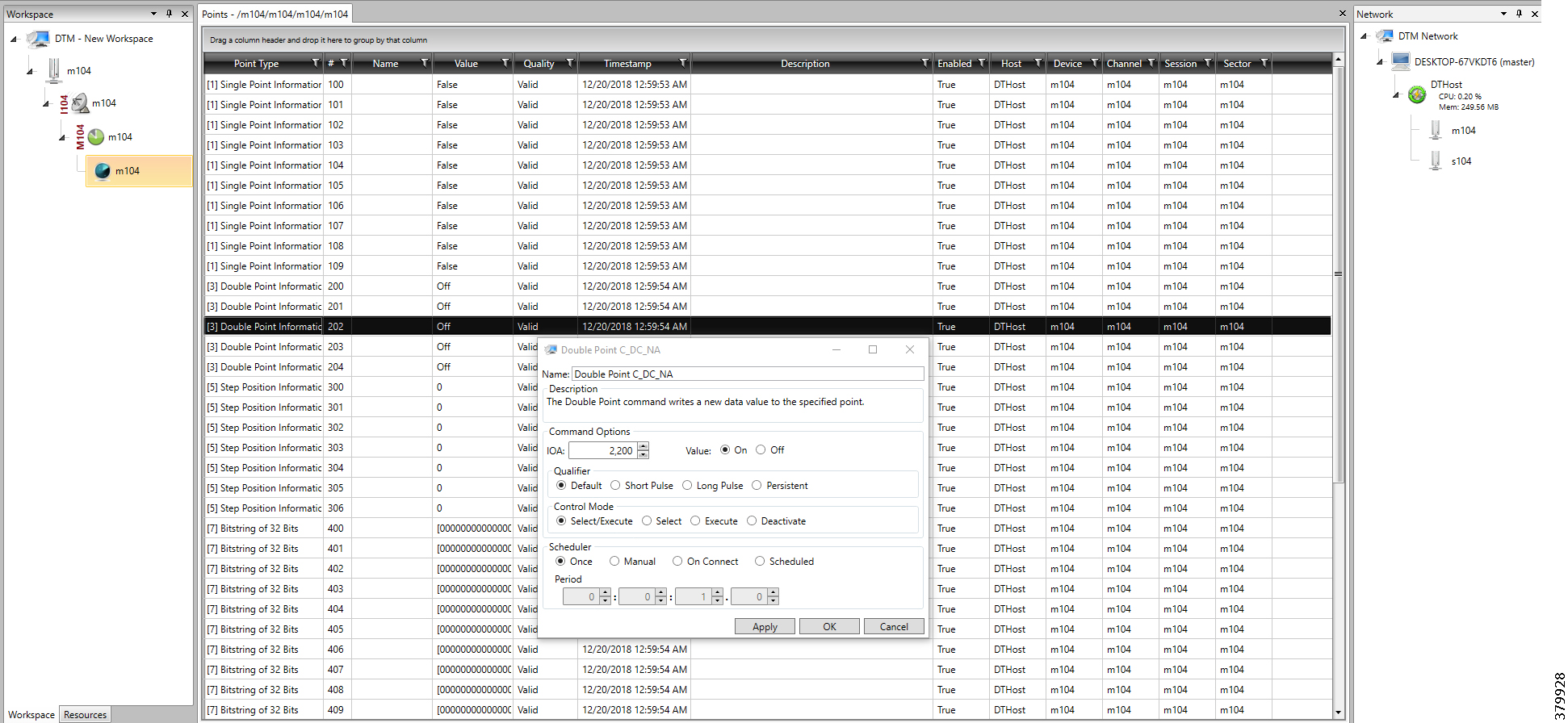

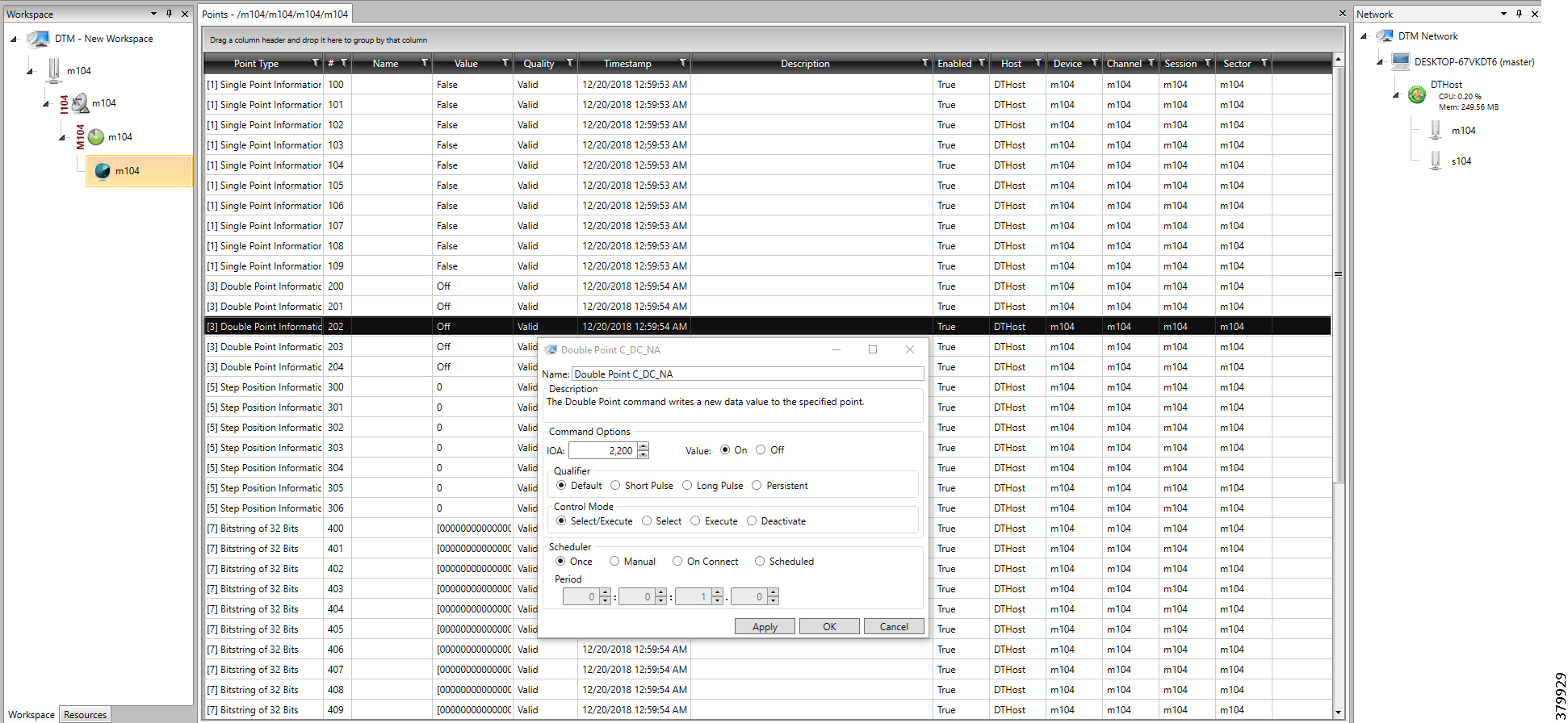

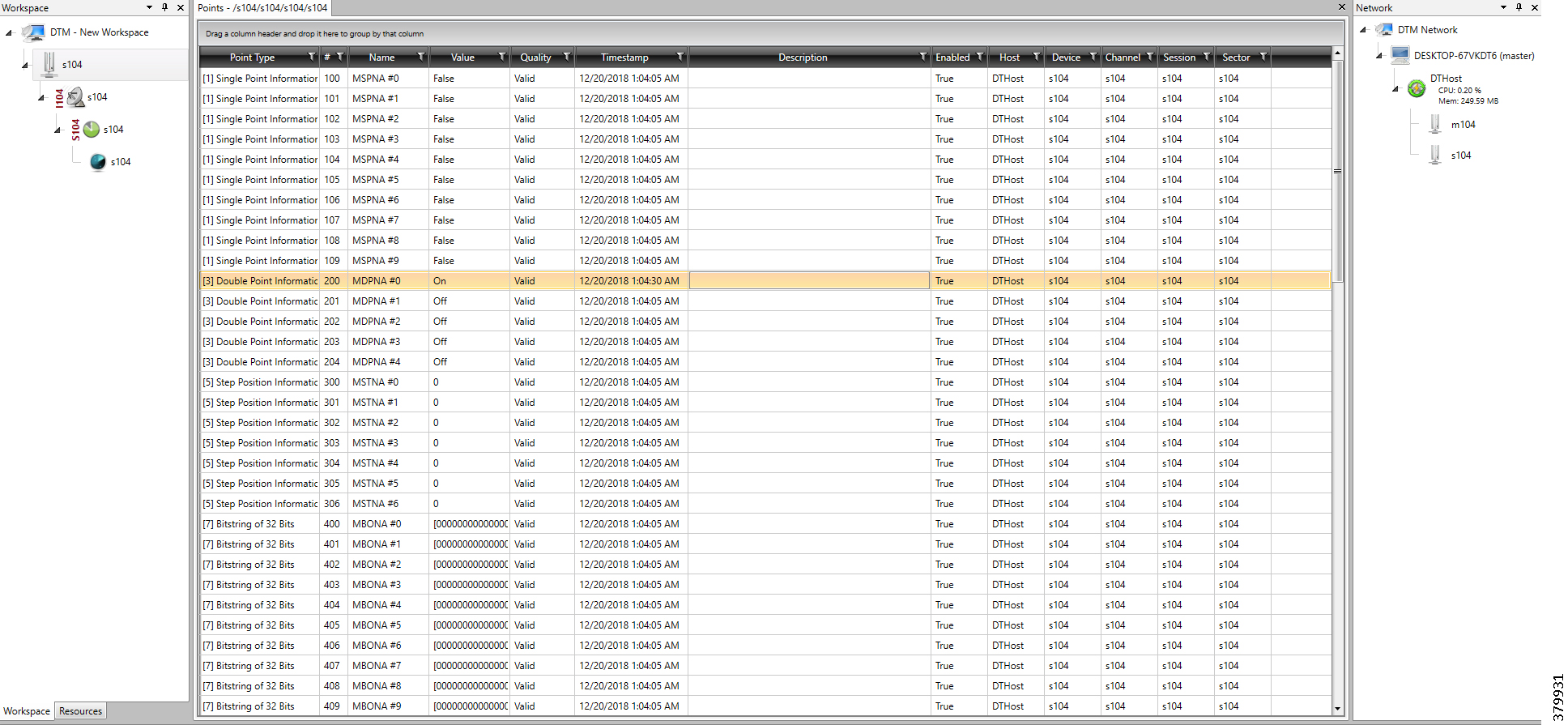

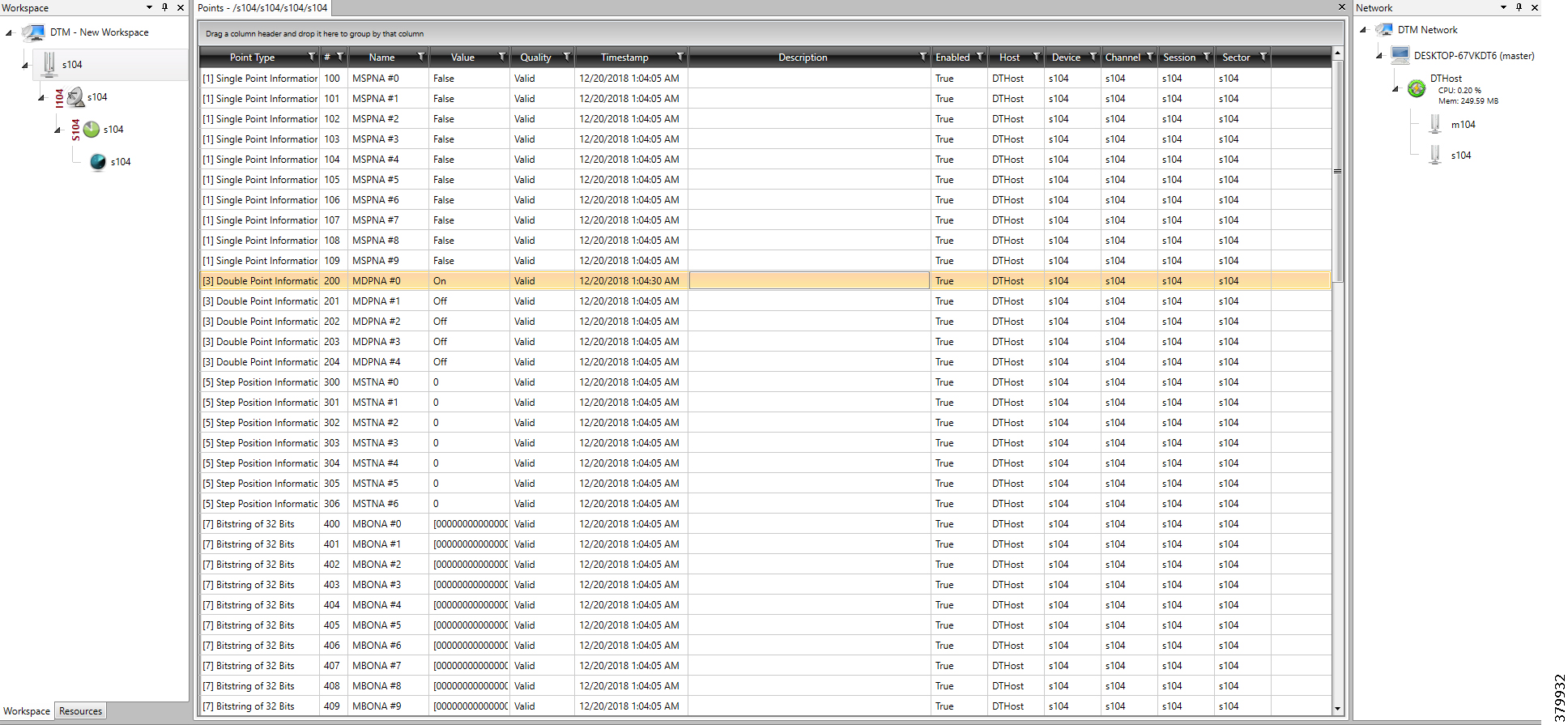

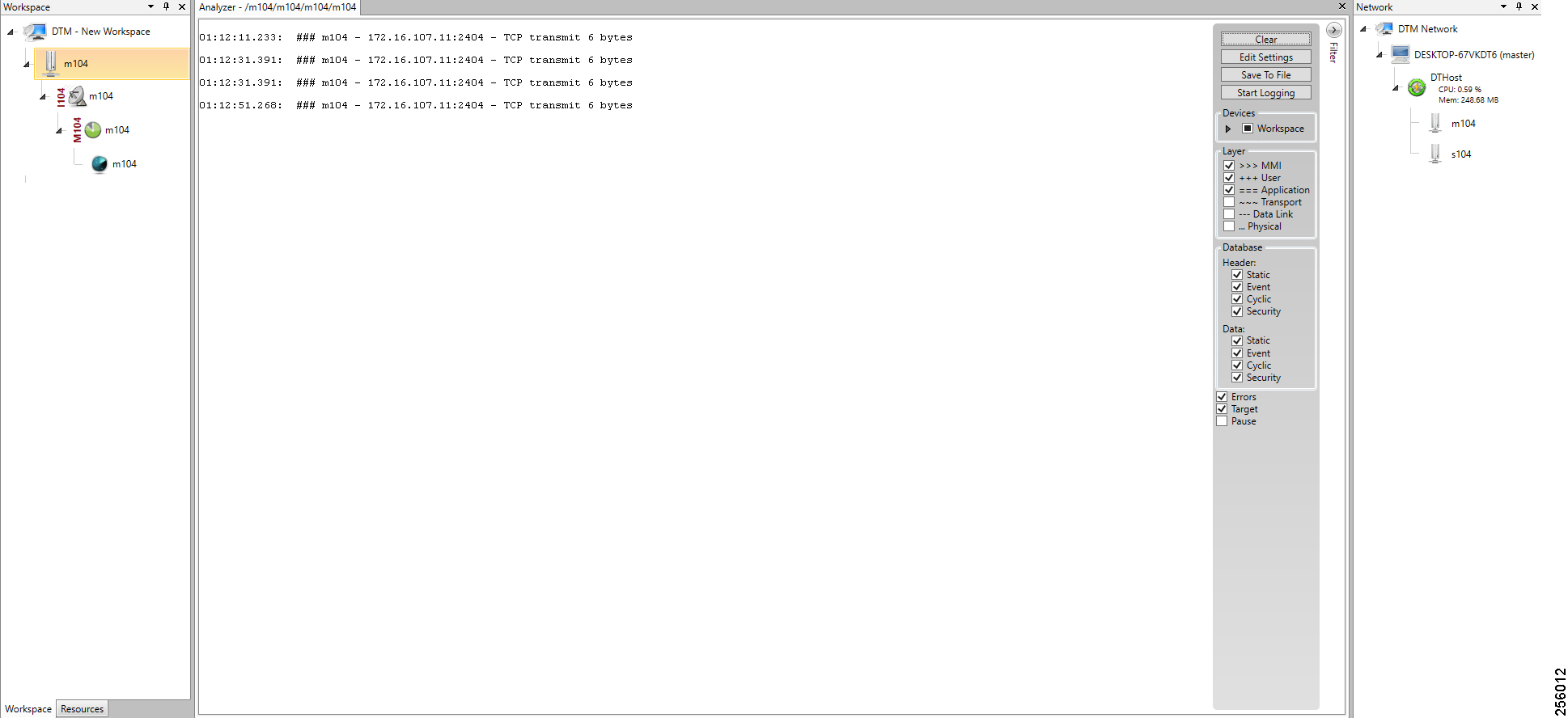

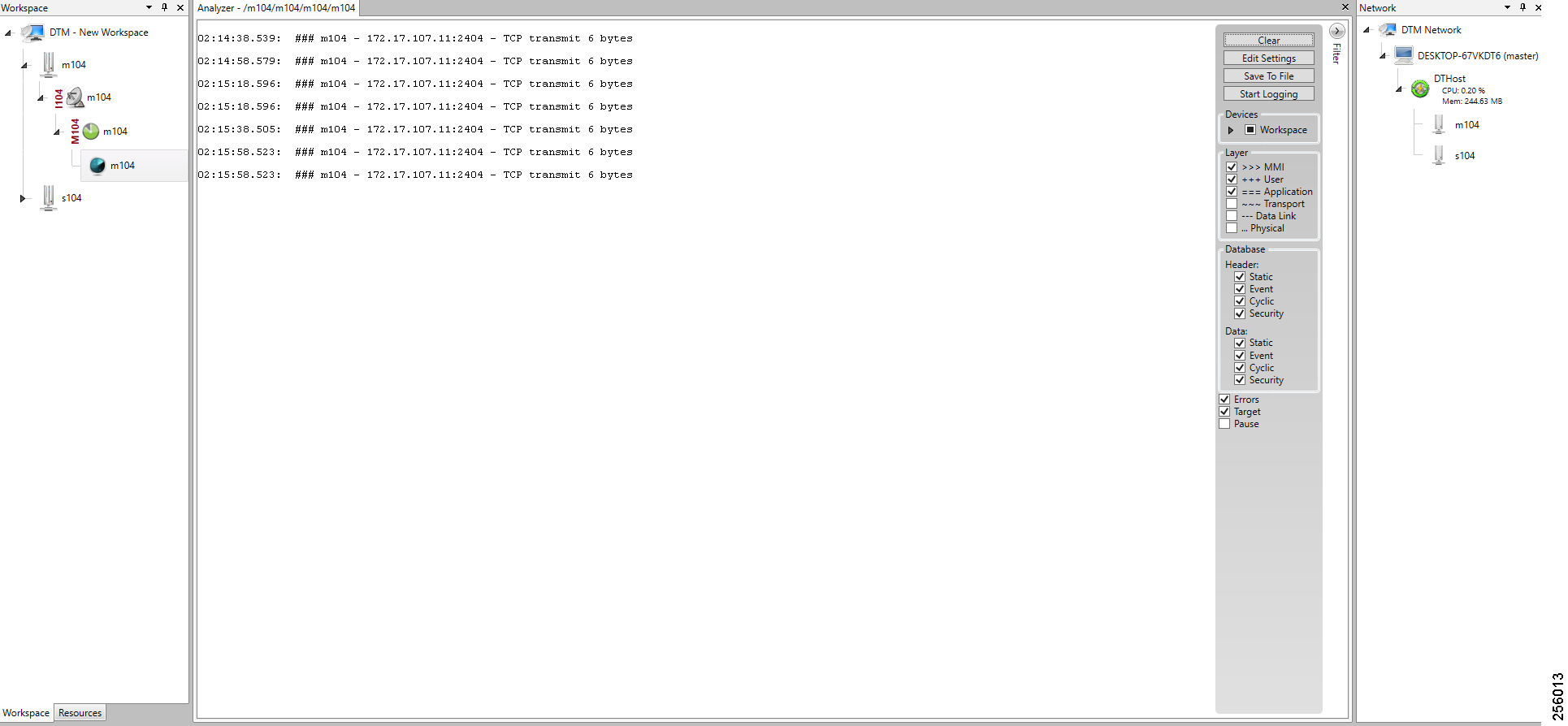

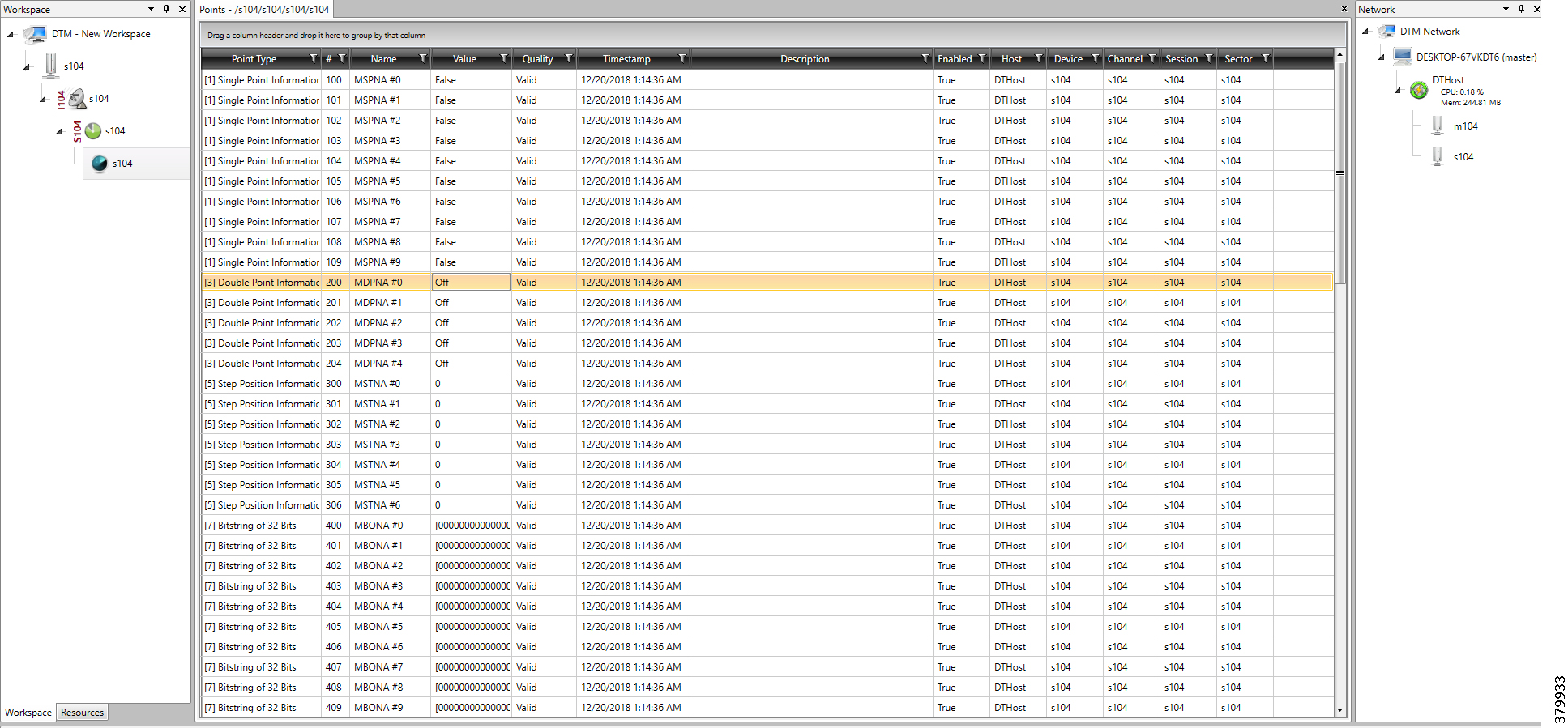

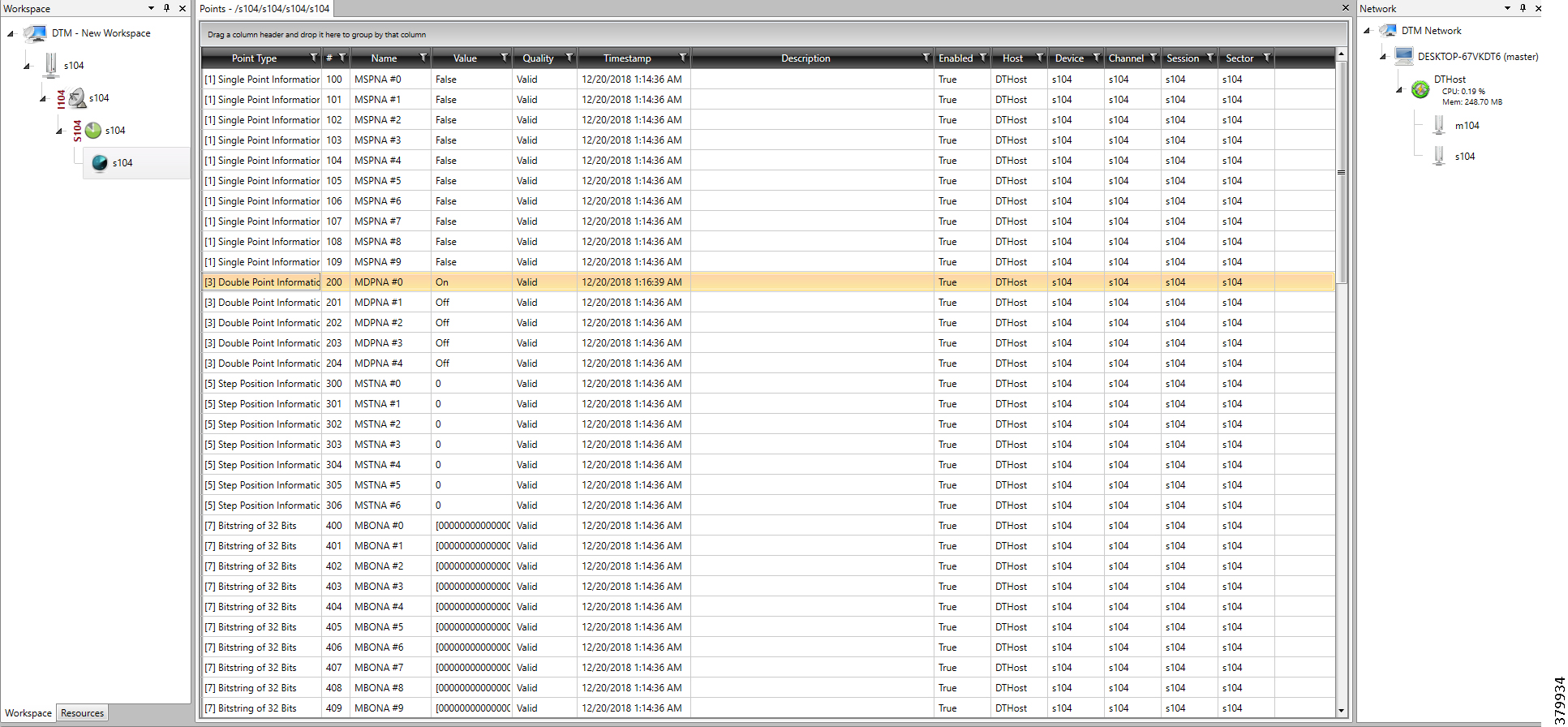

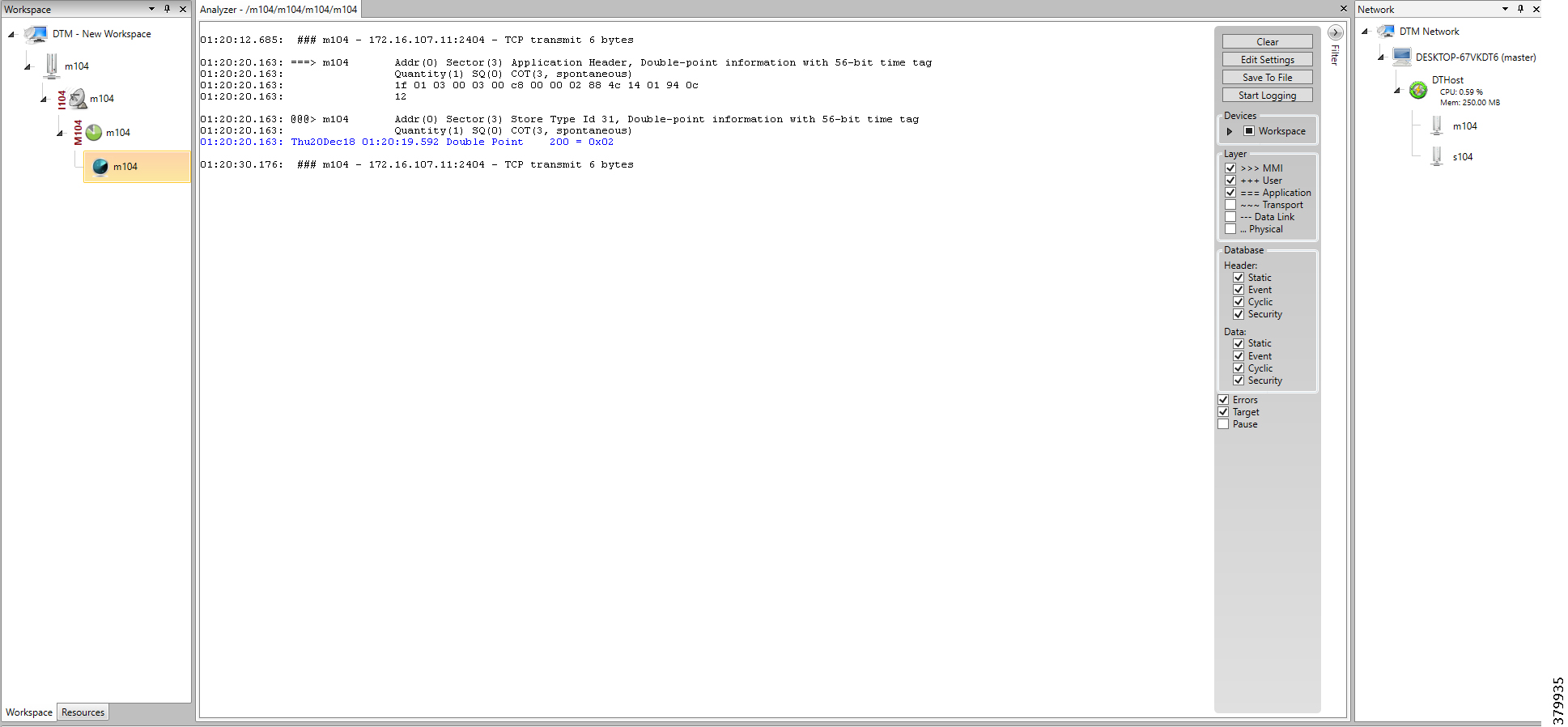

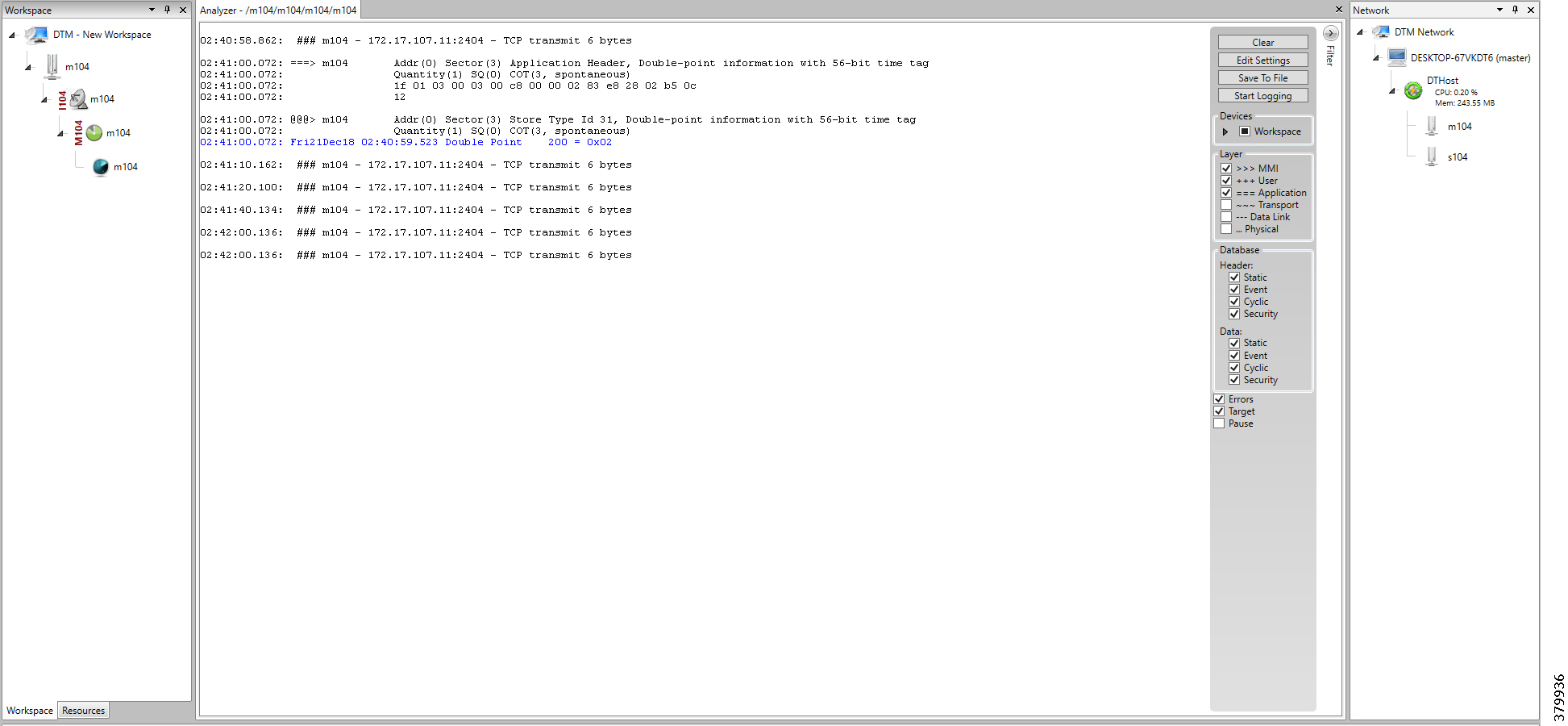

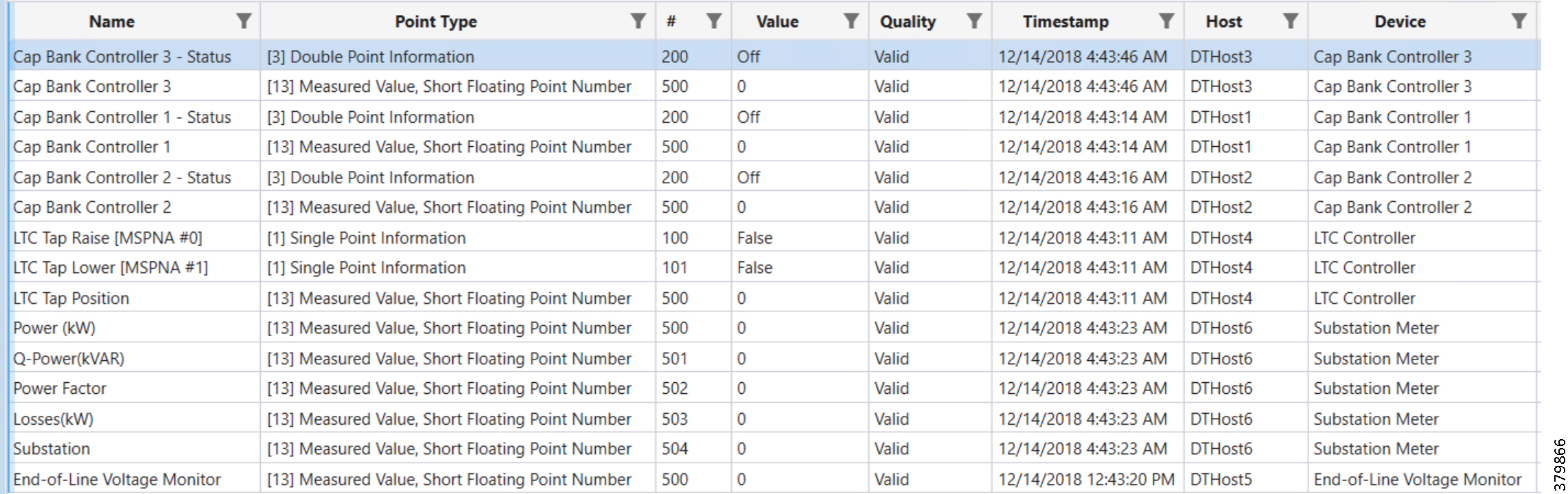

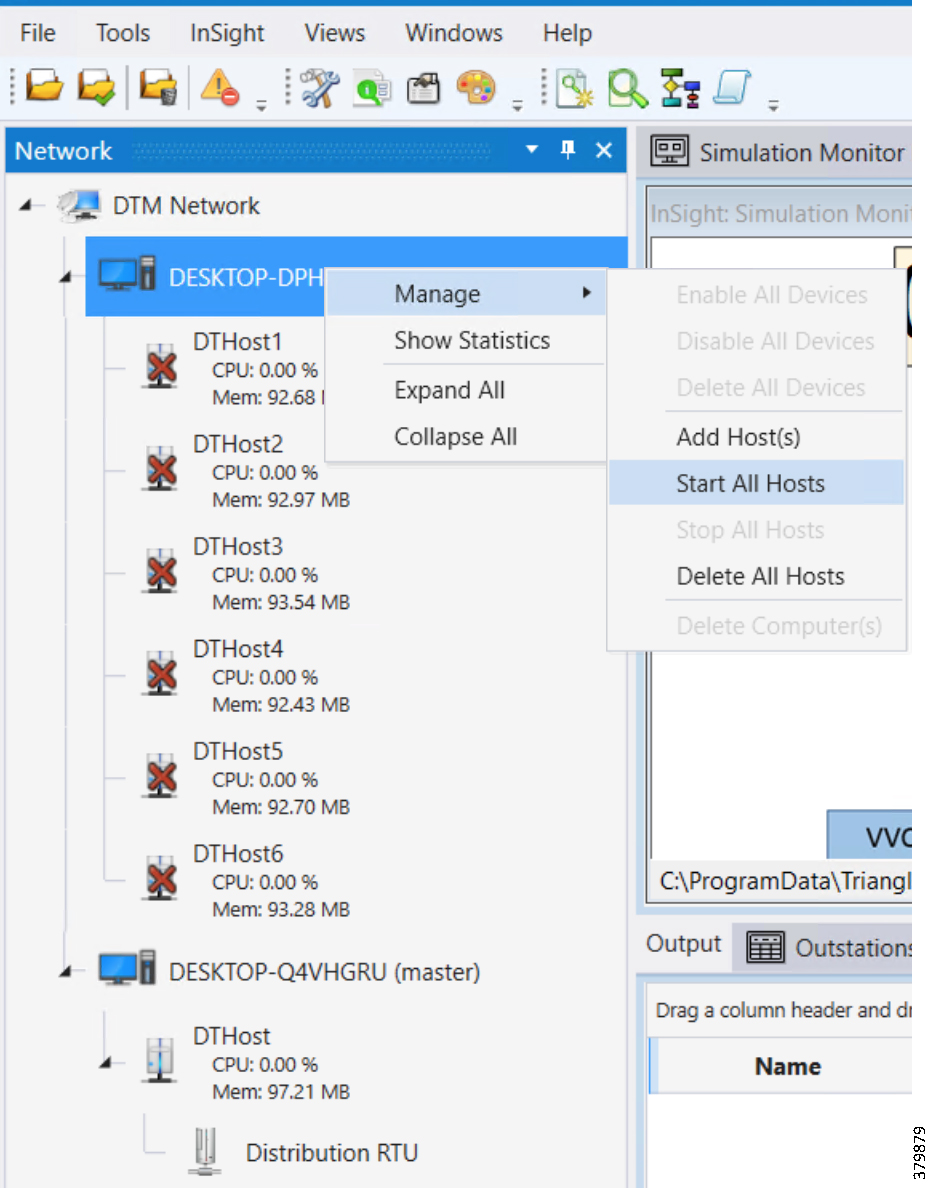

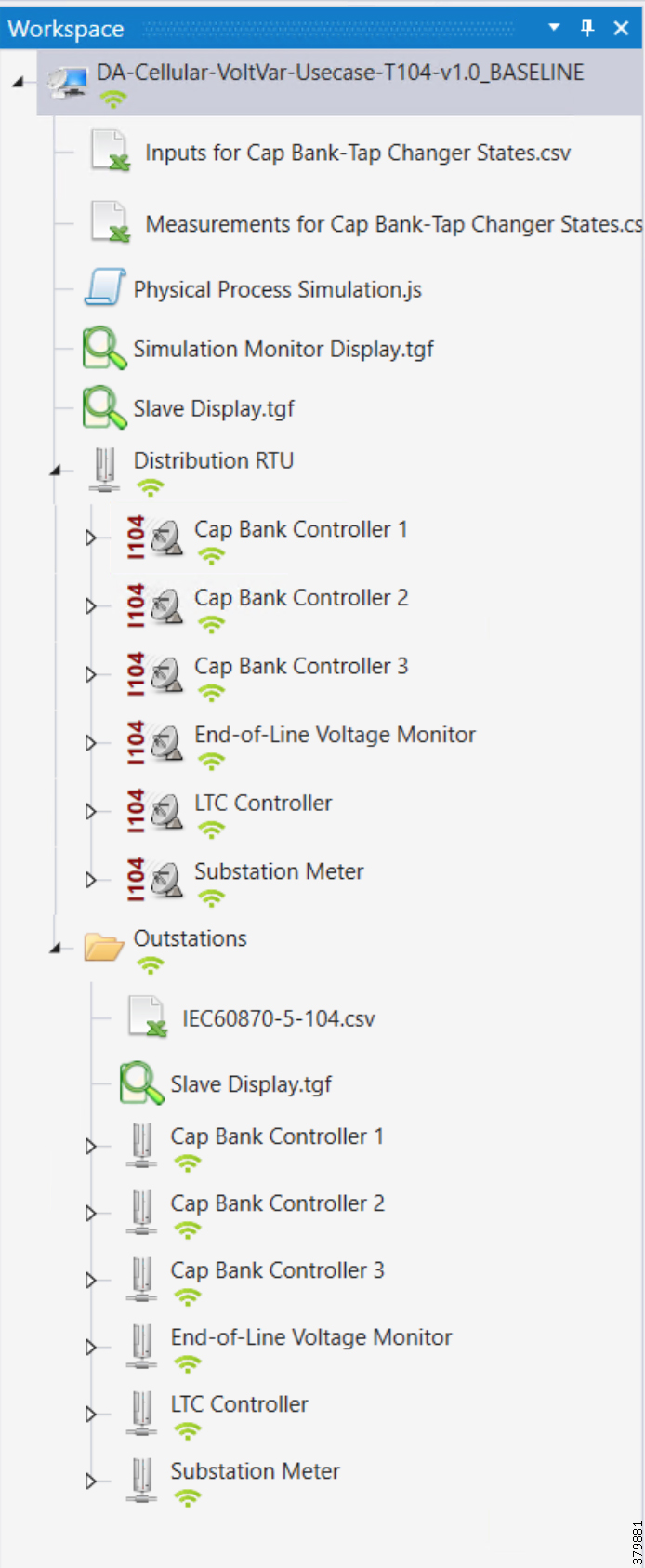

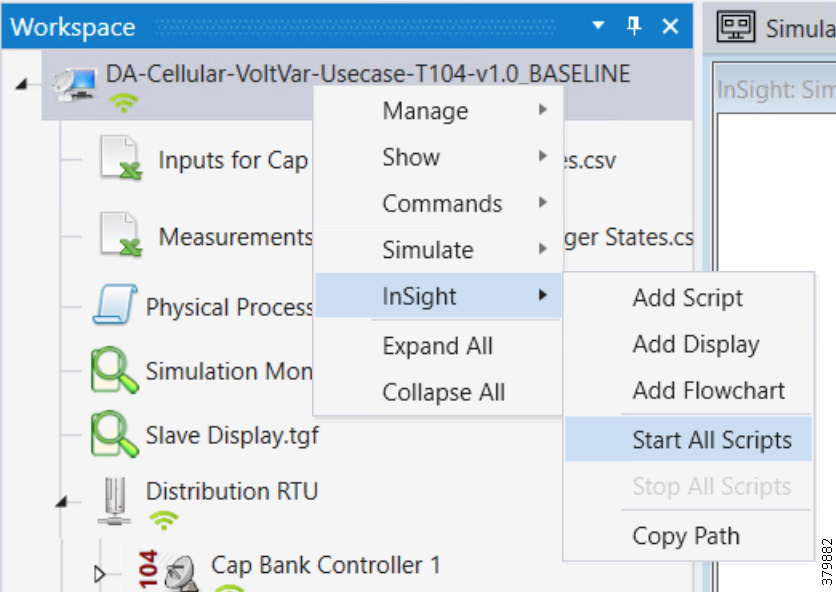

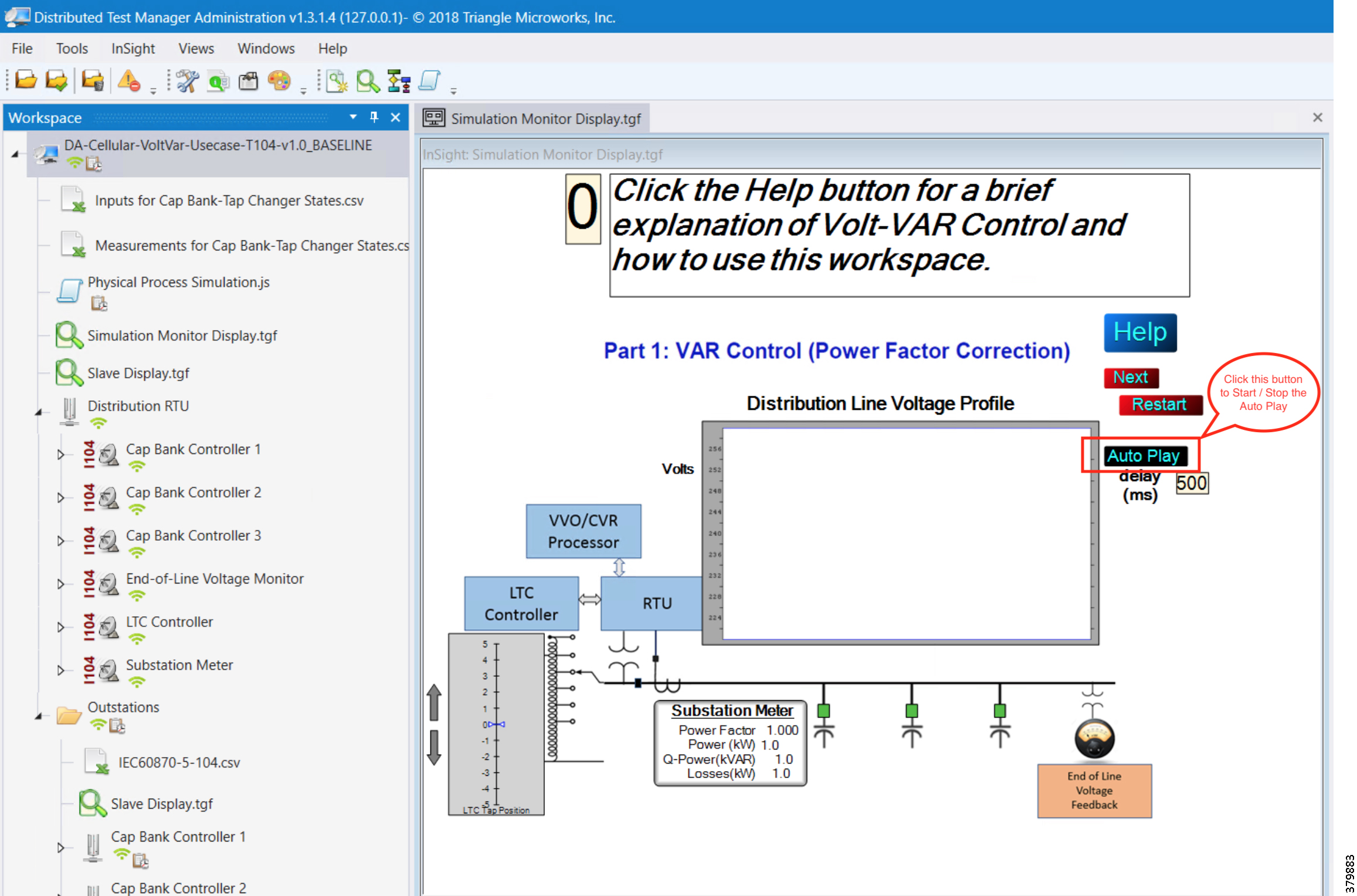

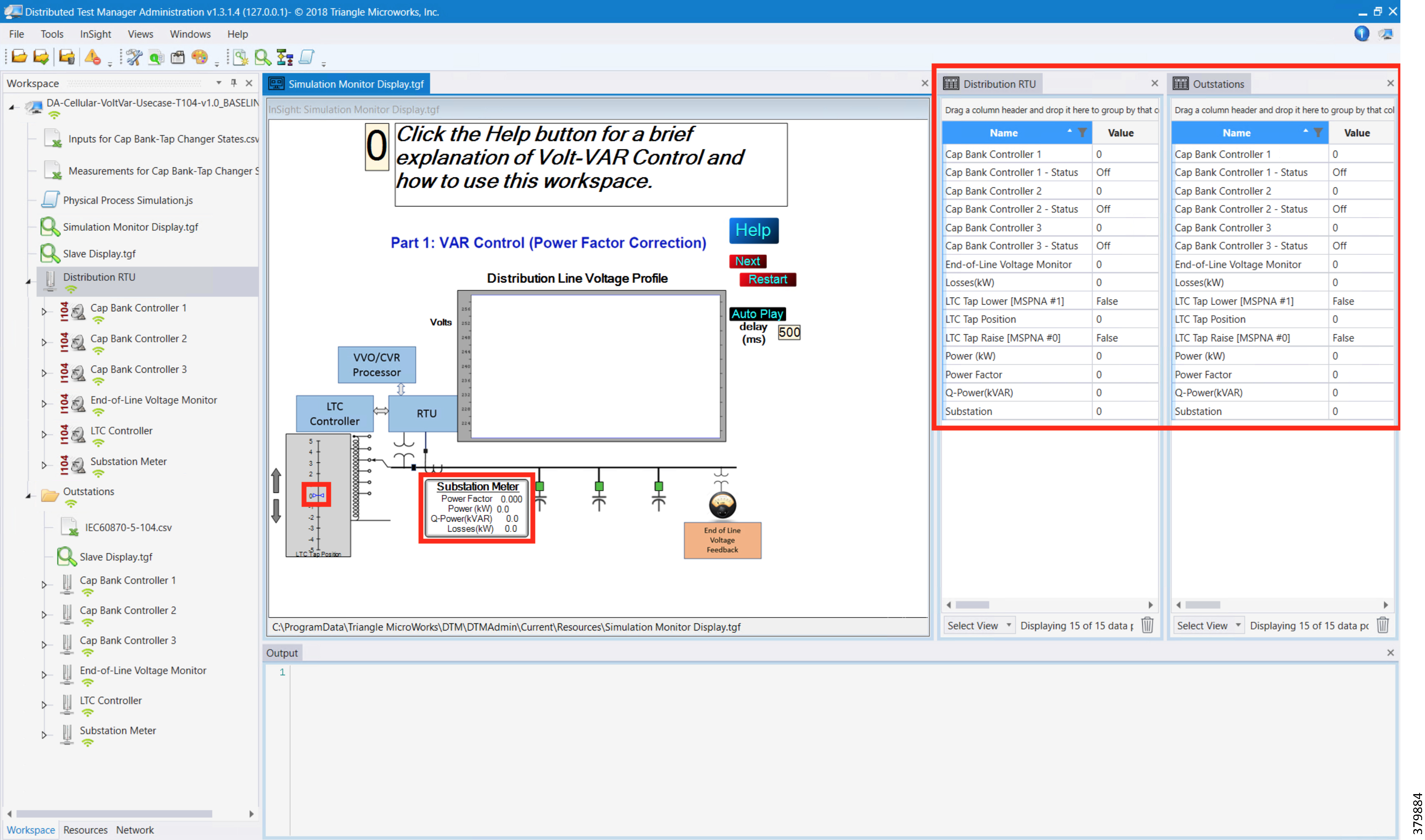

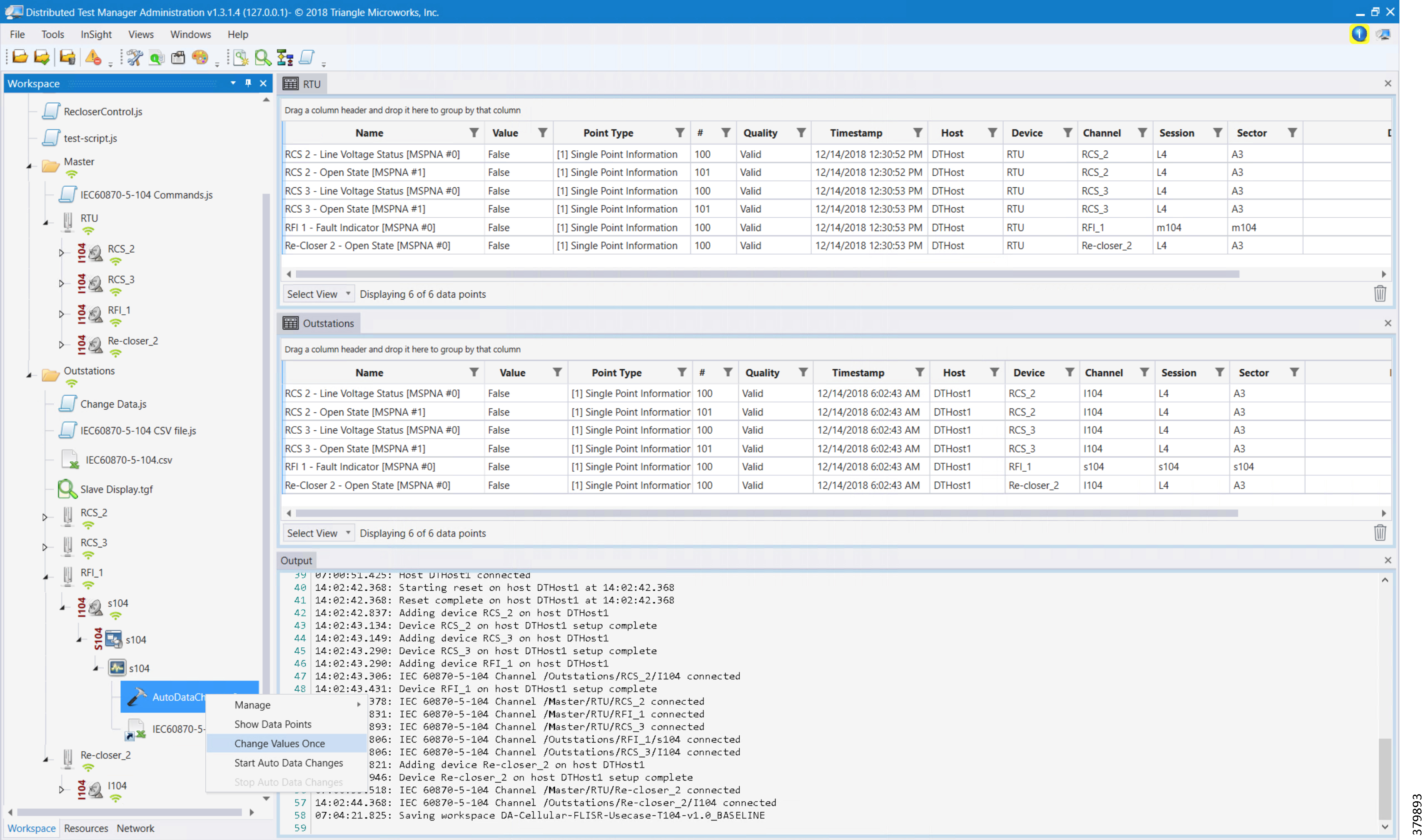

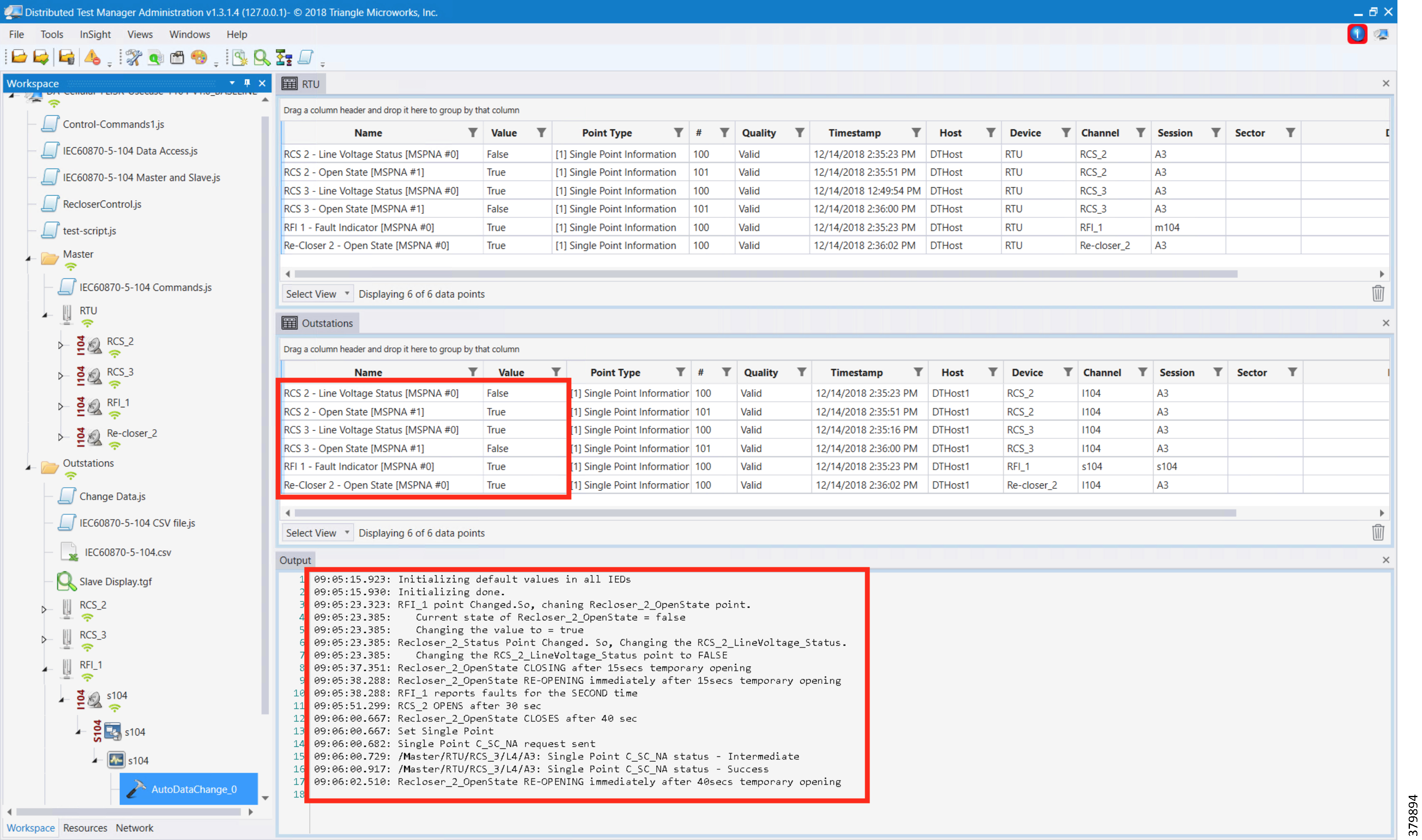

The following components are simulated using the Triangle MicroWorks (Distributed Test Manager or DTM) tool:

1.![]() SCADA Master located in DSO1

SCADA Master located in DSO1

2.![]() SCADA Master located in DSO2

SCADA Master located in DSO2

3.![]() IEDs located in the Utility Controller Devices Block layer

IEDs located in the Utility Controller Devices Block layer

Two Instances of the Solution Validation Topology

Two instances of this topology have been used during this implementation:

1.![]() One instance is located in Cisco Engineering lab premises, with validation done over the Ethernet backhaul:

One instance is located in Cisco Engineering lab premises, with validation done over the Ethernet backhaul:

a.![]() No public internet connectivity

No public internet connectivity

b.![]() WAN Network is simulated inside the engineering lab

WAN Network is simulated inside the engineering lab

c.![]() Is referred to as the Engineering Lab Topology throughout this document

Is referred to as the Engineering Lab Topology throughout this document

2.![]() The second instance is located in the Cisco DMZ premises, with validation done over the cellular backhaul, along with Ethernet WAN:

The second instance is located in the Cisco DMZ premises, with validation done over the cellular backhaul, along with Ethernet WAN:

a.![]() Over public internet connectivity using Cellular SIM Cards, as well as over Ethernet

Over public internet connectivity using Cellular SIM Cards, as well as over Ethernet

b.![]() WAN Network is the service provider's network

WAN Network is the service provider's network

c.![]() Is referred to as Cisco DMZ Headend throughout this document.

Is referred to as Cisco DMZ Headend throughout this document.

Note: The following sections of this guide capture the IP addressing used only in the Engineering Lab topology. For security reasons, Cisco DMZ IP addresses are referred to with abstract names instead of actual IP addresses.

IPv4 and IPv6 Addressing

Addressing in DSO Control Center1

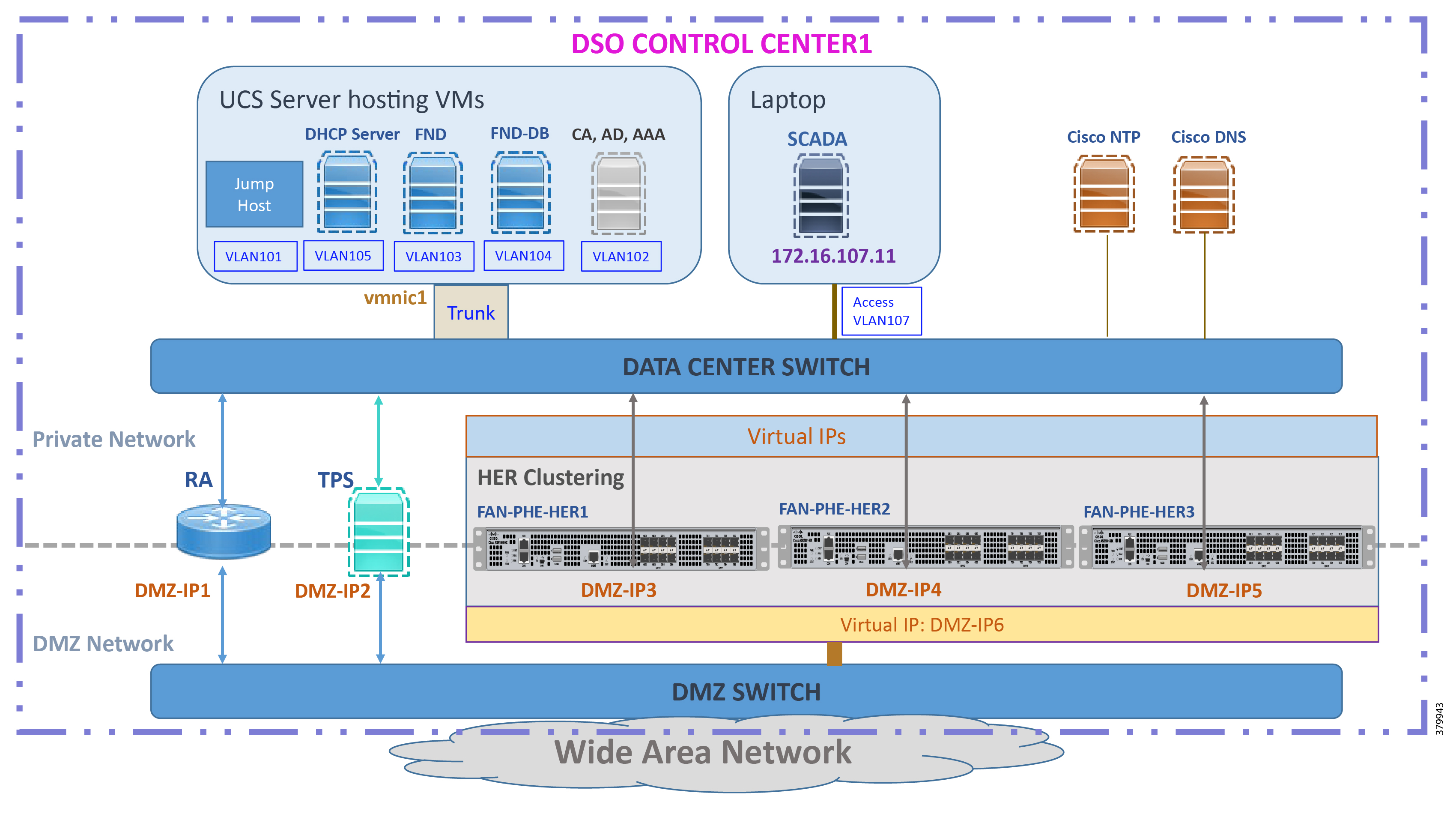

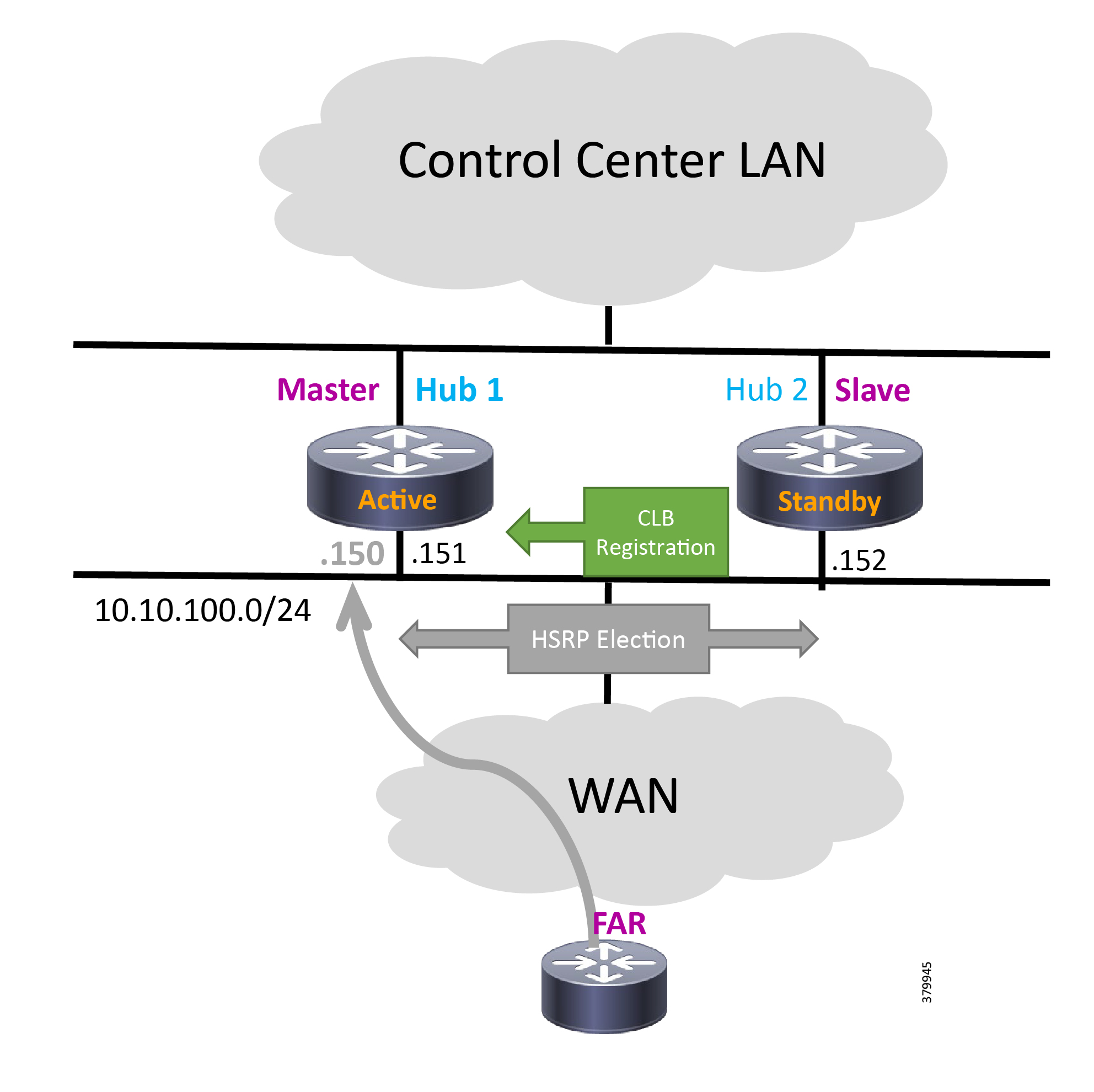

Zooming in on the DSO1 part of the Head End/Control Center block, Figure 4 captures the granular details of the DSO Control Center1:

Figure 4 DSO Control Center 1—Implementation Topology

The DSO Control Center1 is composed of two different networks:

■![]() Addressing in the DMZ Network

Addressing in the DMZ Network

■![]() Addressing in the Private Network

Addressing in the Private Network

Addressing Convention Followed in the Private Network Subnet Selection

Two prefixes are used in the private network of the Control Center:

■![]() 172.16.X.yy in the Engineering Lab Topology

172.16.X.yy in the Engineering Lab Topology

■![]() 192.168.X.yy in the Cisco DMZ Headend

192.168.X.yy in the Cisco DMZ Headend

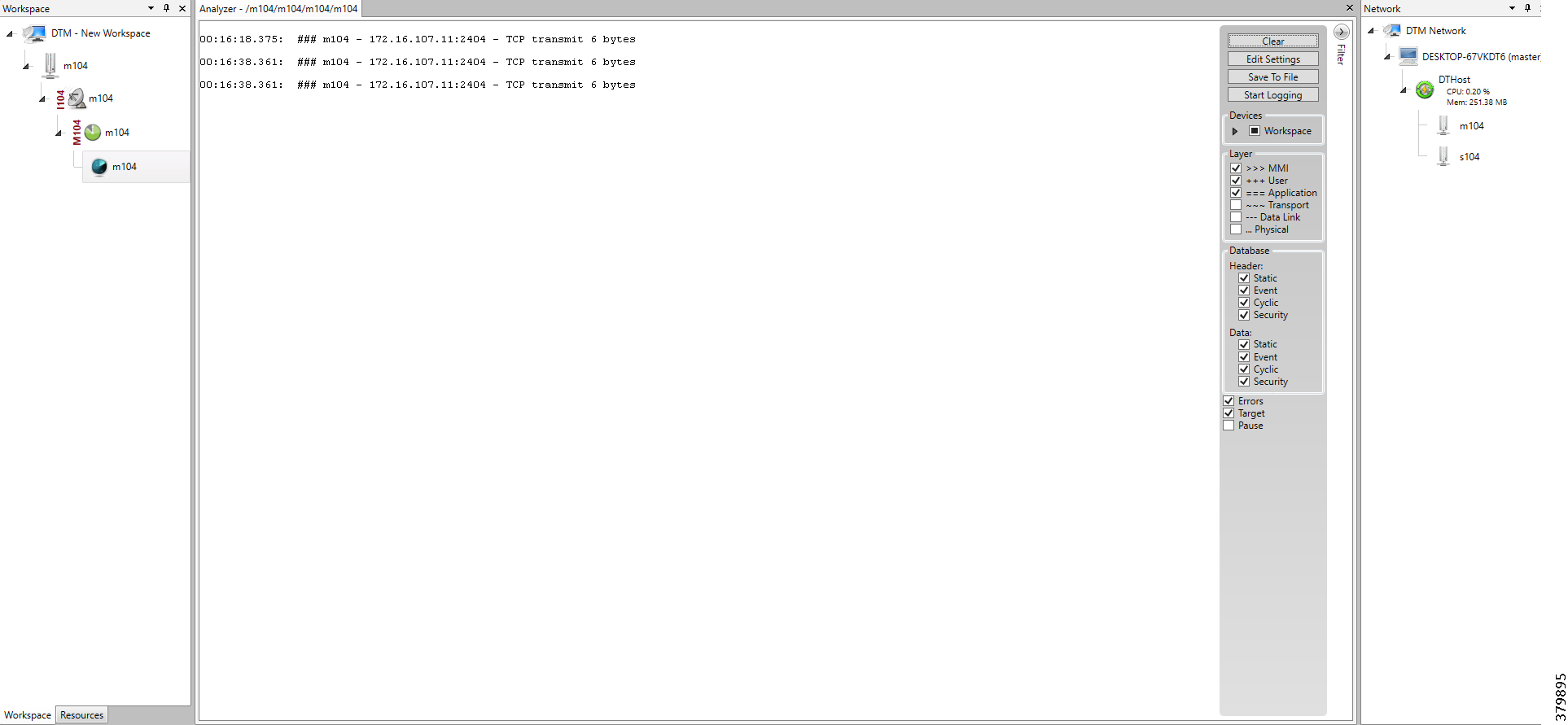

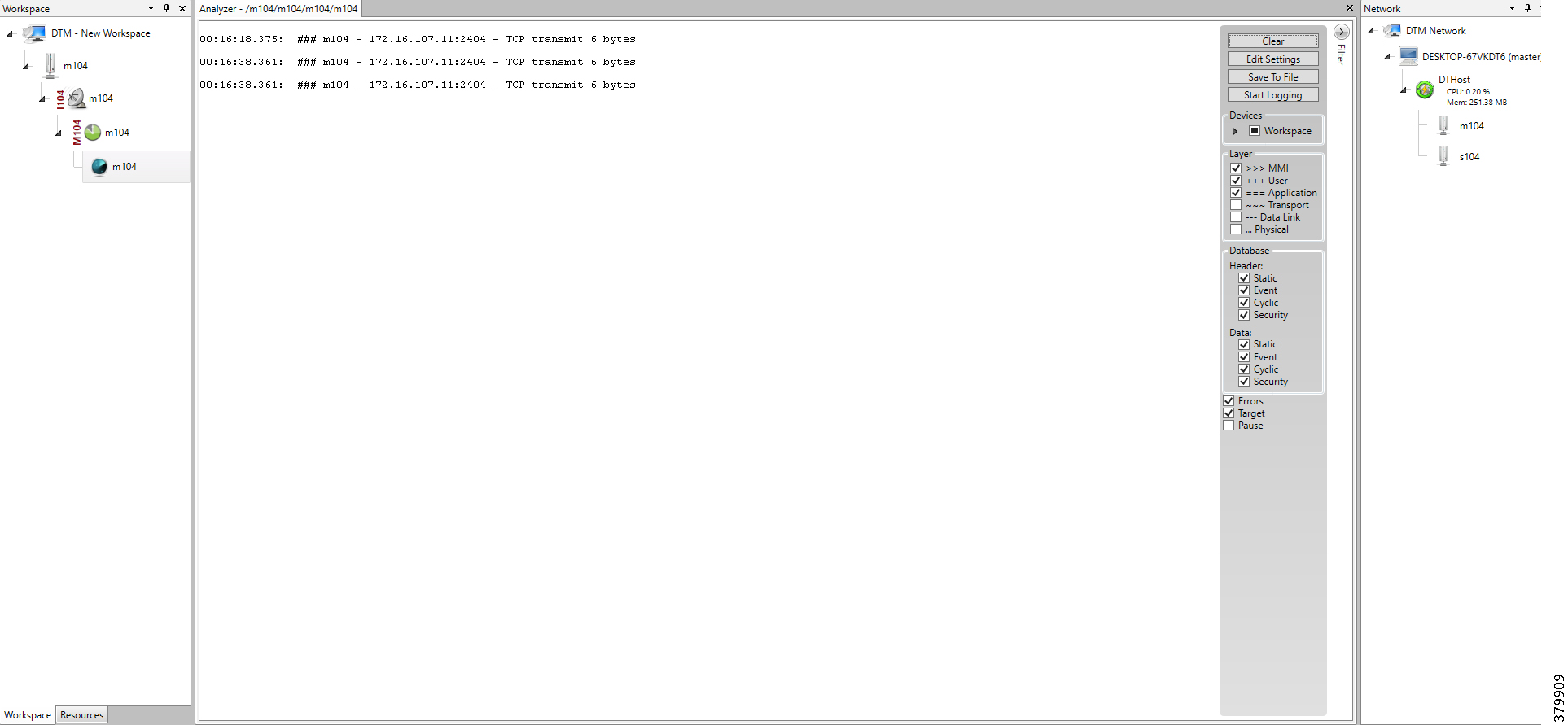

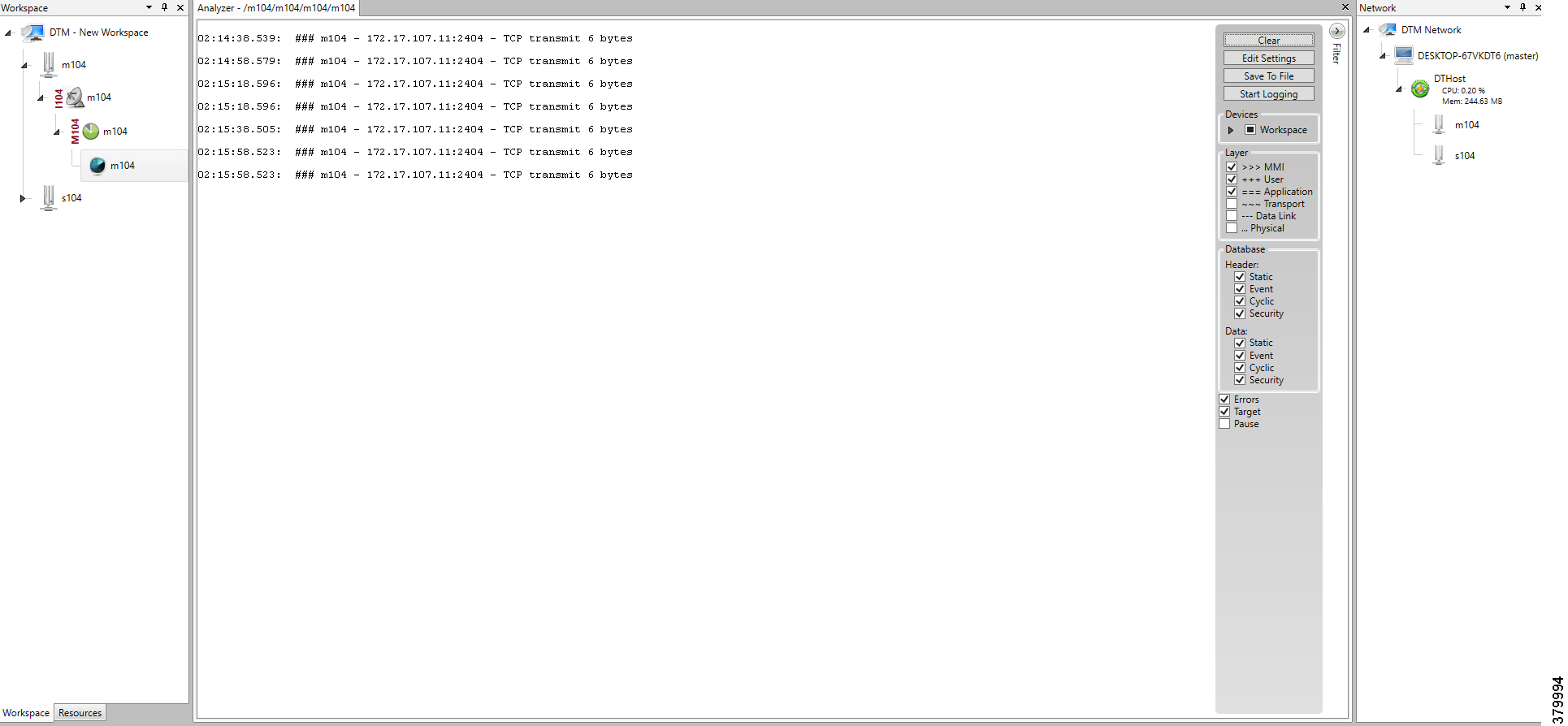

For example, 172.16.103.X represents the network connecting to FND. 172.16.107.X represents the network connecting to the SCADA server.

Note: The third octet also signifies the VLAN used to connect to the corresponding component. For example, VLAN 103 is used for communication with the FND component and VLAN 107 is used for communication with the SCADA server component.

DSO Control Center1: Addressing in the DMZ Network

The topology in Figure 4 on the previous page shows that components that are located in the DMZ Network (reachable over WAN) include the following:

■![]() Tunnel Provisioning Server (TPS)

Tunnel Provisioning Server (TPS)

■![]() HER Cluster—Cluster of ASR 1000 series of routers.

HER Cluster—Cluster of ASR 1000 series of routers.

CC1: Addressing in the Simulated DMZ Network with Engineering Lab Topology

Table 3 and Table 4 capture the IPv4 and IPv6 addresses of the RA, TPS, and HER Cluster (represented in Figure 4) in the “Engineering Lab Topology”:

Note: The Virtual IP for FAN-PHE-HER1, FAN-PHE-HER2, and FAN-PHE-HER3 is 10.10.100.150 in the Engineering Lab Topology.

CC1: Addressing in the Real DMZ Network with Cisco DMZ Headend

This section captures the addressing details of the control center components located in the real DMZ network.

For security reasons, instead of referencing real Cisco DMZ IPv4 and IPv6 addresses, the following representations are used throughout this document:

DSO Control Center1: Addressing in the Private Network

Table 5 captures the addressing details of the components located in the Private Network of Control Center1:

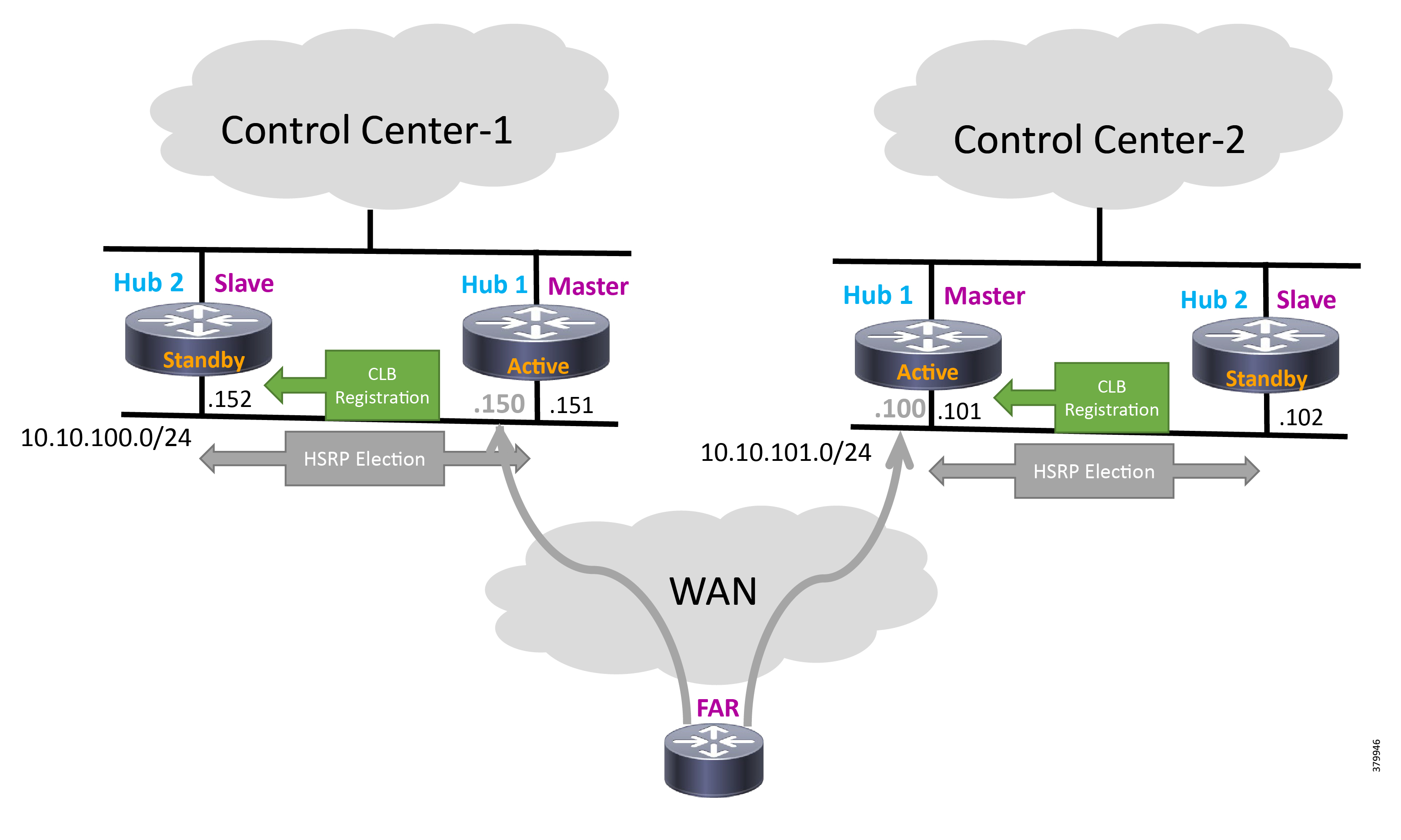

Addressing in DSO Control Center2

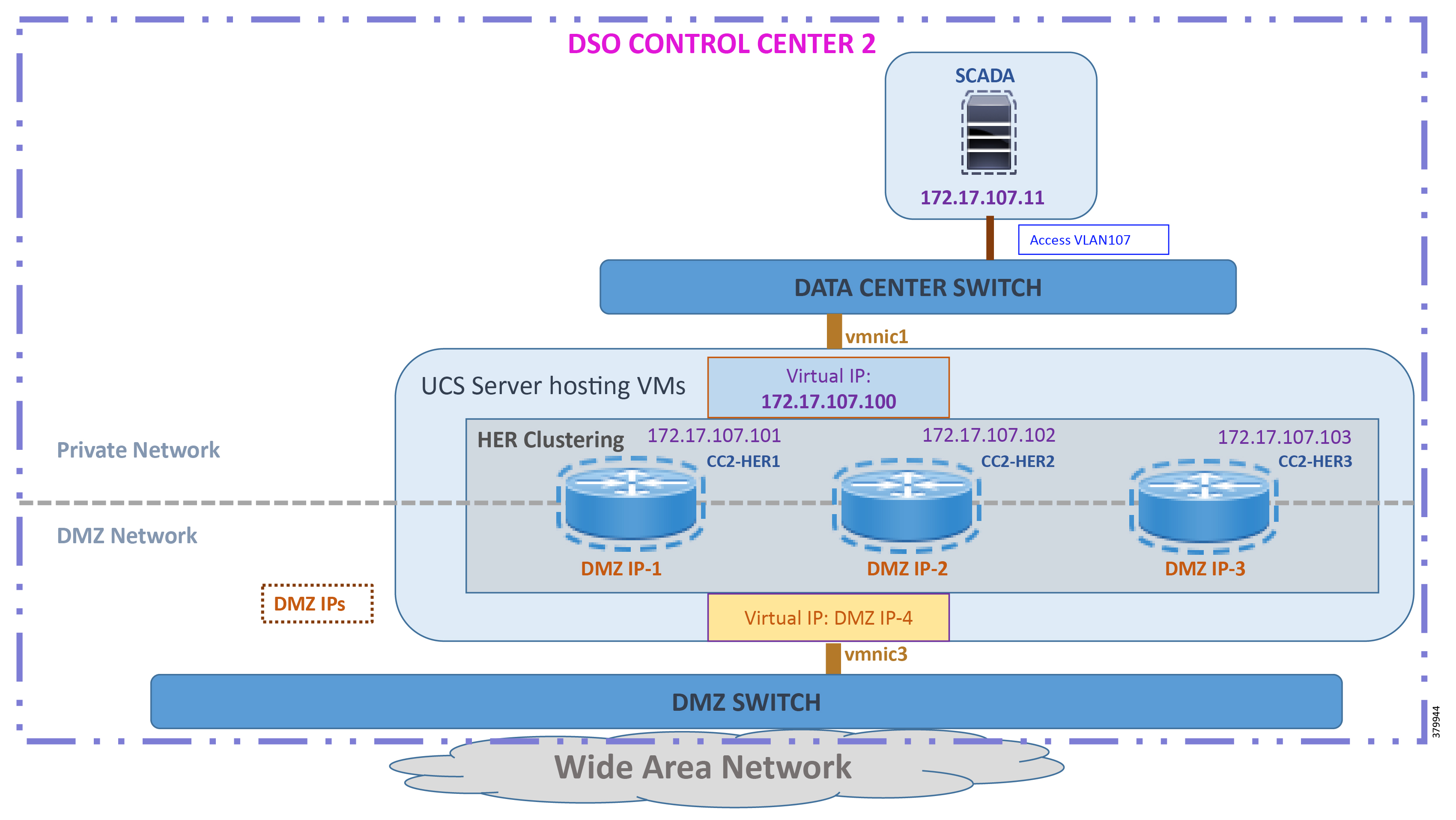

Either the Cisco ASR 1000 series of physical routers or CSR1000v series of virtual routers could be used to serve the role of headend routers (HERs). In high scale deployments, the ASR 1000 is recommended while CSR1000v might be sufficient for low scale deployment. Scale is a metric of the number of SSRs or DA Gateways that needs to be aggregated at the control center.

The ASR 1000 has been validated as part of Control Center1 and CSR1000v has been validated as part of Control Center2.

Figure 5 DSO Control Center 2—Implementation Topology

The DSO Control Center2 is comprised of two types of networks:

–![]() Simulated DMZ in the Engineering Lab Topology

Simulated DMZ in the Engineering Lab Topology

DSO Control Center2: Addressing in the DMZ Network

Similar to the DSO Control Center1, the DMZ Switch is the entry point of the WAN into the DSO Control Center2. The following components are located in the DMZ Network (reachable over WAN):

■![]() HER Cluster—implemented using CSR1000v series of virtual routers on UCS platform:

HER Cluster—implemented using CSR1000v series of virtual routers on UCS platform:

–![]() The HER Cluster performs the role of aggregating the secure tunnels from the DA Gateways and SSRs and provides connectivity to the SCADA server and other application servers.

The HER Cluster performs the role of aggregating the secure tunnels from the DA Gateways and SSRs and provides connectivity to the SCADA server and other application servers.

CC2: Addressing in the Simulated DMZ Network with Engineering Lab Topology

Table 6 and Table 7 capture the IPv4 and IPv6 addresses of the HER Cluster with the instance of the solution validation topology positioned in the Engineering Lab Topology:

Note: The Virtual IP for HER1, HER2, and HER3 is 10.10.101.100 in the Engineering Lab Topology.

CC2: Addressing in the Real DMZ Network with Cisco DMZ Headend

Table 7 captures the addressing details of the Control Center2 components located in the real DMZ network. For security reasons, instead of referencing real Cisco DMZ IPv4 and IPv6 addresses, the following representations are used throughout this document:

DSO Control Center2: Addressing in the Private Network

Table 8 captures the addressing details of the components located in the Private Network of the Control Center2:

IoT Gateway Onboarding and Management

This chapter includes the following major topics:

■![]() Two Logical Categories of Tunnel Provisioning Server/Field Network Director

Two Logical Categories of Tunnel Provisioning Server/Field Network Director

■![]() Bootstrapping of the IoT Gateway

Bootstrapping of the IoT Gateway

■![]() Deployment of the Cisco IoT Gateway

Deployment of the Cisco IoT Gateway

■![]() Bootstrapping and ZTD of the Cisco IoT Gateway at the Deployment Location

Bootstrapping and ZTD of the Cisco IoT Gateway at the Deployment Location

■![]() IoT Gateway Validation Matrix

IoT Gateway Validation Matrix

This chapter corresponds to the “Zero Touch Onboarding of Cisco IOS Routers” chapter in the Distribution Automation - Secondary Substation Design Guide. Field Network Director (FND) is used as the NMS in this solution.

IoT Gateway Onboarding has been made very simple:

1.![]() The brand new IoT Gateway could be unpacked from the box.

The brand new IoT Gateway could be unpacked from the box.

2.![]() It could be subjected to bootstrapping using plug-and-play (PnP) infrastructure.

It could be subjected to bootstrapping using plug-and-play (PnP) infrastructure.

3.![]() After bootstrapping, the IoT Gateway could be powered off and deployed at the desired deployment location. In some cases, bootstrapping could occur directly out of the deployment location itself.

After bootstrapping, the IoT Gateway could be powered off and deployed at the desired deployment location. In some cases, bootstrapping could occur directly out of the deployment location itself.

4.![]() When powered on, ZTD then happens with the IoT Gateway.

When powered on, ZTD then happens with the IoT Gateway.

5.![]() As a result, the device could be made fully operational with zero manual configuration.

As a result, the device could be made fully operational with zero manual configuration.

As part of IoT Gateway onboarding with ZTD, the IoT Gateways are registered with the FND. From that point onwards, the FND located in the Control Center could be used to remotely monitor/manage/troubleshoot the IoT Gateways (which are spread across the entire Distribution Automation Network) and the Secondary Substations.

This process has three phases:

1.![]() Bootstrapping of the IoT Gateway

Bootstrapping of the IoT Gateway

2.![]() Deployment of the IoT Gateway

Deployment of the IoT Gateway

3.![]() Remote Monitoring/Management/Troubleshooting of the IoT Gateway.

Remote Monitoring/Management/Troubleshooting of the IoT Gateway.

The design guide talks about the following two different approaches for bootstrapping versus deployment of the IoT Gateway:

■![]() Approach 1—IoT Gateway Bootstrapped in staging location, deployed in a different location

Approach 1—IoT Gateway Bootstrapped in staging location, deployed in a different location

■![]() Approach 2—IoT Gateway Bootstrapped straight out of deployed location

Approach 2—IoT Gateway Bootstrapped straight out of deployed location

Both approaches are now supported by Cisco IoT Gateways and this guide supports both the approaches.

With Approach 1, bootstrapping of the IoT Gateways is done at the dedicated staging location. Once the devices are bootstrapped successfully, they are powered off and transported to the final deployment locations, where the devices are deployed and powered on.

With Approach 2, bootstrapping of the IOT Gateways is done at the deployment location. Once the devices are bootstrapped successfully, the ZTD process begins and no manual intervention is required,

Two Logical Categories of Tunnel Provisioning Server/Field Network Director

Bootstrapping TPS/FND

The TPS/FND located in the staging/bootstrapping environment that helps with PnP bootstrapping of the IoT Gateways is referred to as bootstrapping TPS and bootstrapping FND.

Network Operating Center TPS/FND

The TPS/FND located in the NOC/Control Center environment that helps with ZTD of IoT Gateways is referred to as the NOC or Control Center TPS/FND. This TPS/FND located in the DSO Control Center helps with management of the IoT Gateways.

Note: The bootstrapping TPS/FND could be the same as or different from the NOC TPS/FND depending upon the chosen approach. With Approach 1, two different pairs of TPS/FND have been implemented. They are referred to as:

With Approach 2, the same pair of TPS/FND serves the purpose of bootstrapping TPS/FND and NOC TPS/FND.

For general implementation of TPS/FND, please refer to the detailed steps covered in the following sections of the Cisco FAN-Headend Deep Dive Implementation and FAN Use Cases guide:

■![]() Implementing Tunnel Provisioning Server

Implementing Tunnel Provisioning Server

■![]() Implementing Field Network Director

Implementing Field Network Director

The Cisco IoT Field Network Director Installation Guide could also be referred to for implementation of TPS/FND.

Note: This guide focuses on the implementation details for enhancing the TPS/FND servers to also serve the functionality of Bootstrapping TPS and Bootstrapping FND.

Note: Please refer to the “Certificate/Considerations for PnP and ZTD ” section in the Distribution Automation - Secondary Substation Design Guide for Common Name and Subject Alternate Name requirements while creating certificates for the Bootstrapping TPS/FND and NOC TPS/FND.

Bootstrapping of the IoT Gateway

Bootstrapping can also be referred to with the following terminology:

■![]() Application of manufacturing configuration onto IoT Gateway

Application of manufacturing configuration onto IoT Gateway

■![]() Generation of Express Configuration

Generation of Express Configuration

On the bootstrapping FND, import the bootstrapping csv file and then assign the IoT Gateways to the correct bootstrapping group. Bootstrapping will occur automatically when the IoT gateway is powered on.

Note: To bootstrap the IoT Gateway, in the case of Approach 1, just connect the IoT Gateway to the Ethernet PnP Staging switch, and then power it on. In the case of Approach 2, just insert the LTE SIM cards (or connect the Ethernet link) with internet access on the IoT Gateway and power it on.

Bootstrapping is achieved with the help of the Cisco Network PnP solution. This section focuses on building the infrastructure required for bootstrapping to happen. The “Cisco Network PnP - Available Methods” section of the Design Guide discusses multiple methods for PnP server discovery. Three PnP server discovery methods, which have been implemented as part of this guide, are:

■![]() PnP server discovery through Cisco PnP Connect—validated with Approach 2

PnP server discovery through Cisco PnP Connect—validated with Approach 2

■![]() PnP server discovery through DHCP server—validated with Approach 1

PnP server discovery through DHCP server—validated with Approach 1

■![]() PnP server discovery through manual PnP profile—validated with Approach 1

PnP server discovery through manual PnP profile—validated with Approach 1

Preparing the Bootstrapping Infrastructure

The bootstrapping infrastructure, which involves multiple actors, is captured in Table 9:

This section is discussed in the following phases:

■![]() Certificate Creation and Installation

Certificate Creation and Installation

■![]() Installation of Bootstrapping TPS

Installation of Bootstrapping TPS

■![]() Installation of Bootstrapping FND

Installation of Bootstrapping FND

Prerequisites

Prerequisites include the following:

■![]() TPS and FND server must be up and running.

TPS and FND server must be up and running.

■![]() This section focuses only on the incremental portions to make the regular TPS/FND as bootstrapping TPS/FND.

This section focuses only on the incremental portions to make the regular TPS/FND as bootstrapping TPS/FND.

■![]() Routing reachability over IPv4 and/or IPv6 networks from IoT Gateways to TPS.

Routing reachability over IPv4 and/or IPv6 networks from IoT Gateways to TPS.

Certificate Creation and Installation

This section captures the parameters that need to be considered while creating the certificate for the TPS (PnP Proxy) and FND (PnP server).

Note: For detailed instructions about certificate creation, please refer to the section “Creation of Certificate Templates and Certificates” of the Cisco FAN-Headend Deep Dive Guide at the following URL:

■![]() https://salesconnect.cisco.com/#/content-detail/da249429-ec79-49fc-9471-0ec859e83872

https://salesconnect.cisco.com/#/content-detail/da249429-ec79-49fc-9471-0ec859e83872

Implementation and FAN Use Cases are available under Cisco SalesConnect.

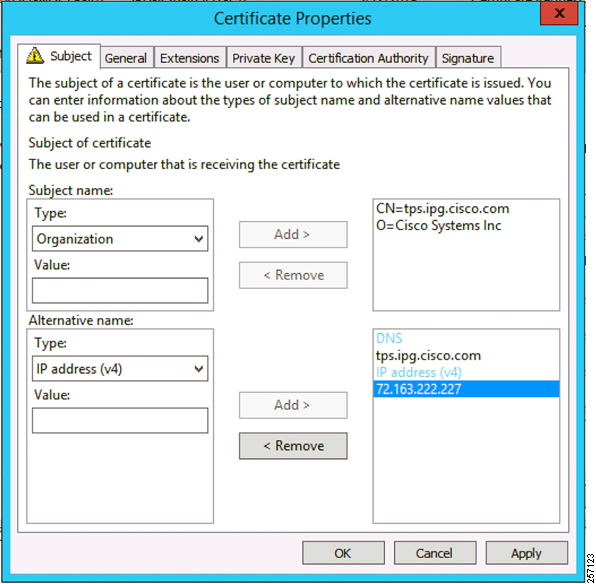

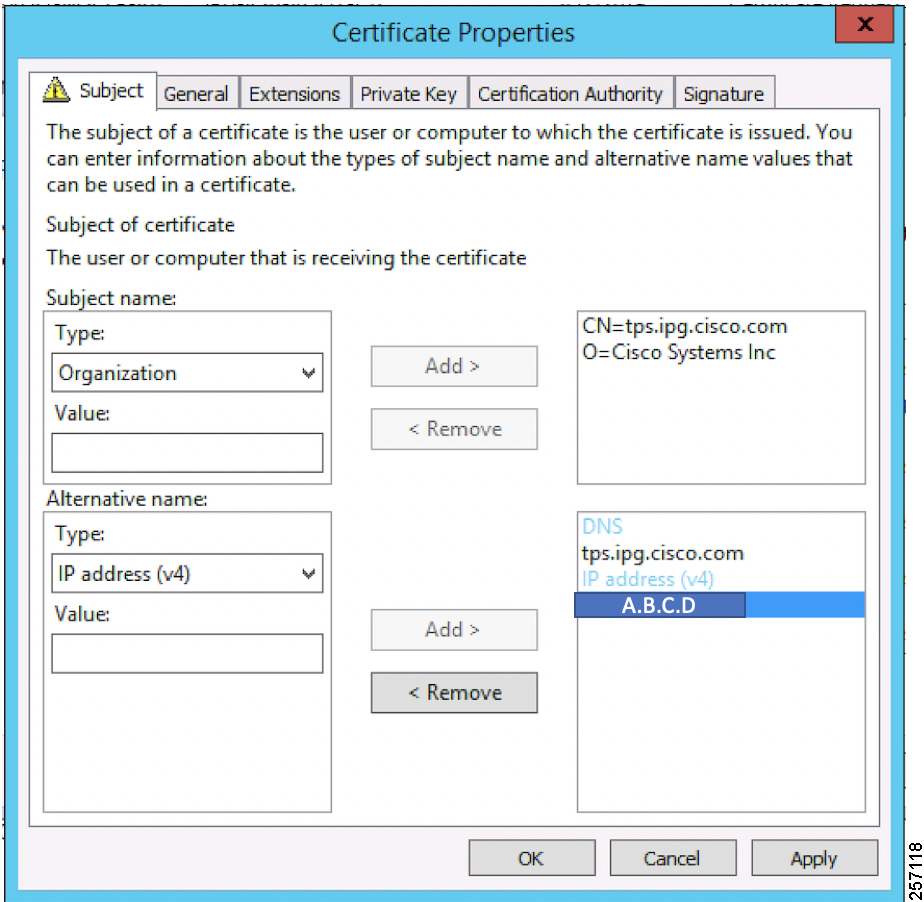

Certificate Creation for Bootstrapping TPS

The certificate for the TPS must be created with both the Subject Name and the Subject Alternative Name fields populated.

Figure 6 TPS Certificate Parameters for PnP Bootstrapping

The Subject Name is the Common Name that must be set to the FQDN of the PnP Proxy.

The Subject Alternative Name must be set to the FQDN of the PnP Proxy, along with the optional IP address. The Subject Alternative Name is required for PnP to work.

The enrolled certificate is exported as PnP-TPS.pfx and is protected with a password.

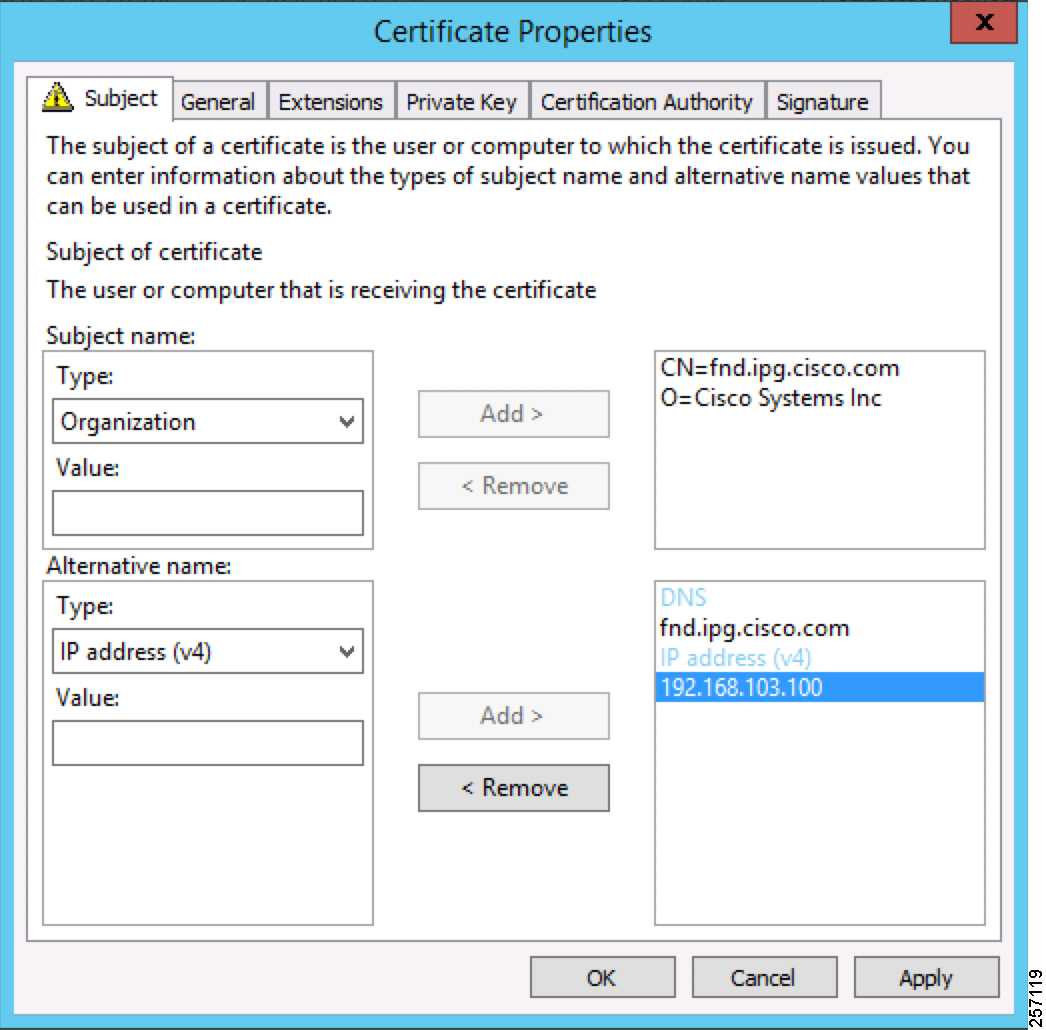

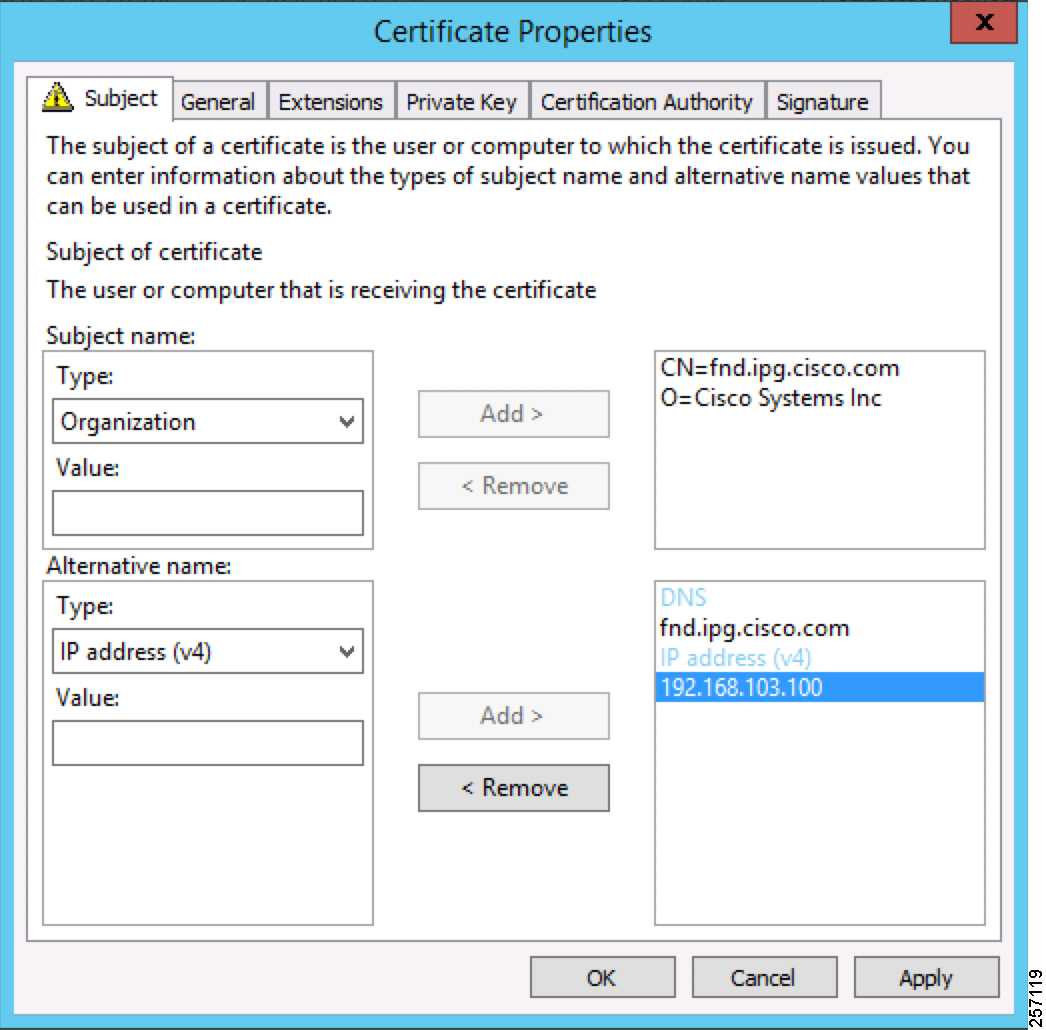

Certificate Creation for Bootstrapping FND

The FND certificate must be created with both the Subject Name and Subject Alternative Name fields populated.

Figure 7 FND Certificate Parameters for FND Bootstrapping

The Subject Name is the Common Name that must be set to the FQDN of the PnP Server.

The Subject Alternative Name must be set to the FQDN of the PnP Server, along with the optional IP address. The Subject Alternative Name is required for PnP to work.

The enrolled certificate is exported as PnP-FND.pfx and is protected with a password.

Installation of Bootstrapping TPS

The bootstrapping procedure in this implementation considers the use of TPS as PnP Proxy.

Note: As TPS is used in this implementation, TPS would represent itself as the PnP server for the IoT Gateways. Therefore, TPS is referred to as the PnP Proxy.

For installation of TPS, please refer to the detailed steps covered under the section “Implementing Tunnel Provisioning Server” of the Cisco FAN-Headend Deep Dive Implementation and FAN Use Cases guide at the following URL:

■![]() https://salesconnect.cisco.com/#/content-detail/da249429-ec79-49fc-9471-0ec859e83872

https://salesconnect.cisco.com/#/content-detail/da249429-ec79-49fc-9471-0ec859e83872

TPS Certificate Installation on the Bootstrapping TPS

For installation of the certificate on the Bootstrapping TPS, please refer to the detailed steps covered under the section

“Certificate Enrollment Phase for TPS Proxy Server” of the Cisco FAN - Headend Deep Dive Implementation and FAN Use Cases Guide.

Note: Please use PnP-TPS.pfx instead of TPS.pfx while enrolling the certificate on the TPS.

Following are the crisp steps:

# To view the content of the “Pnp-TPS.pfx” certificate:

Cisco SUDI Certificate Installation on the Bootstrapping TPS

Cisco SUDI CA can be installed into the cgms_keystore of TPS using the following command:

The Cisco SUDI CA file “cisco-sudi-ca.pem” can be fetched from the FND.

Installation of Bootstrapping FND

For installation of FND, please refer to the detailed steps covered under the section “Implementing Field Network Director” of the Cisco FAN-Headend Deep Dive Implementation and FAN Use Cases Guide at the following URL:

■![]() https://salesconnect.cisco.com/#/content-detail/da249429-ec79-49fc-9471-0ec859e83872

https://salesconnect.cisco.com/#/content-detail/da249429-ec79-49fc-9471-0ec859e83872

FND Certificate Installation on the Bootstrapping FND

For installation of certificate on the Bootstrapping FND, please refer to the detailed steps covered under the section “Certificate Enrollment onto FND's Keystore” of the Cisco FAN Headend Deep Dive Implementation and FAN Use Cases Guide.

Note: Please use PnP-FND.pfx instead of FND.pfx while enrolling the certificate on the FND.

Cisco SUDI Certificate Installation on the Bootstrapping FND

Cisco SUDI CA can be installed into the cgms_keystore of FND using the following command:

Configuration of Bootstrapping TPS

This section covers the configuration steps and the final verification steps on the TPS.

TPS Proxy Properties Configuration

TPS Proxy Properties file needs to be configured with the following details:

■![]() inbound-bsproxy-destination: Address to which the bootstrapping requests be forwarded.

inbound-bsproxy-destination: Address to which the bootstrapping requests be forwarded.

■![]() enable-bootstrap-service: Is bootstrapping service enabled/disabled?

enable-bootstrap-service: Is bootstrapping service enabled/disabled?

■![]() bootstrap-proxy-listen-port: Port on which the PnP Proxy must be listening for processing bootstrapping requests (default port is 9125).

bootstrap-proxy-listen-port: Port on which the PnP Proxy must be listening for processing bootstrapping requests (default port is 9125).

Name resolution entries have to be present for FND FQDN in the /etc/hosts file.

Mandatory Verification Checks on TPS Proxy

The verification checks include the following:

■![]() FND FQDN entry in /etc/hosts.

FND FQDN entry in /etc/hosts.

■![]() TPS must have three certificates installed into the cgms_keystore:

TPS must have three certificates installed into the cgms_keystore:

–![]() Certificate signed by Utility PKI for TPS (with private key)

Certificate signed by Utility PKI for TPS (with private key)

–![]() Public Certificate of the Utility PKI CA server

Public Certificate of the Utility PKI CA server

–![]() Public Certificate of the Cisco SUDI CA

Public Certificate of the Cisco SUDI CA

■![]() Hostname consistency with the certificate.

Hostname consistency with the certificate.

■![]() There shouldn't be any unreachable name servers in /etc/resolv.conf.

There shouldn't be any unreachable name servers in /etc/resolv.conf.

■![]() NTP daemon should be running. Time should be synchronized.

NTP daemon should be running. Time should be synchronized.

■![]() Necessary firewall ports must have been opened up, if the firewall/iptables/ip6tables are enabled:

Necessary firewall ports must have been opened up, if the firewall/iptables/ip6tables are enabled:

–![]() TCP Port 9125 to process http communication

TCP Port 9125 to process http communication

–![]() TCP port 9120 to process https communication

TCP port 9120 to process https communication

TPS must have three certificates installed into the cgms_keystore:

■![]() The certificate entry 'root' represents the Utility PKI CA certificate.

The certificate entry 'root' represents the Utility PKI CA certificate.

■![]() The certificate entry 'sudi' represents the Cisco SUDI CA certificate.

The certificate entry 'sudi' represents the Cisco SUDI CA certificate.

■![]() The certificate entry 'cgms' represents the private certificate of the TPS server signed by the (custom) Utility PKI CA server.

The certificate entry 'cgms' represents the private certificate of the TPS server signed by the (custom) Utility PKI CA server.

keytool -list -keystore /opt/cgms-tpsproxy/conf/cgms_keystore:

Hostname should match certificate Common Name/SAN:

No unreachable name servers should exist. Either the name servers should be present and reachable or they should be empty. Any unreachable name server address entry must be taken care of or removed under the network interface configuration.

NTP daemon should be running. Time should be synchronized:

Note: The TPS server should be time synchronized. Otherwise, the https communication from the IoT Gateway might not reach the TPS Proxy Application.

Configuration of Bootstrapping FND

This section covers the configuration steps and the final verification steps on the FND.

The CGMS Properties file needs to be configured with the following details:

■![]() proxy-bootstrap-ip: Address of the PnP Proxy from which the bootstrapping requests are processed

proxy-bootstrap-ip: Address of the PnP Proxy from which the bootstrapping requests are processed

■![]() enable-bootstrap-service: Enable/Disable the bootstrapping service

enable-bootstrap-service: Enable/Disable the bootstrapping service

■![]() bootstrap-fnd-alias: The trust point alias to be used during bootstrapping of the IoT Gateway

bootstrap-fnd-alias: The trust point alias to be used during bootstrapping of the IoT Gateway

■![]() ca-fingerprint: fingerprint of the 'root' trustpoint

ca-fingerprint: fingerprint of the 'root' trustpoint

Name resolution entries have to be present for TPS FQDN in the /etc/hosts file.

The IOT gateway should be able to communicate with the value given against the proxy-bootstrap-ip. IF IPv4 is used, it must be reachable from the IOT gateway. If FQDN is used, it must be DNS resolvable and reachable from the IoT gateway.

Mandatory Verification Checks on FND

Verification checks include the following:

■![]() TPS FQDN entry in the /etc/hosts file.

TPS FQDN entry in the /etc/hosts file.

■![]() FND must have three certificates installed into the cgms_keystore:

FND must have three certificates installed into the cgms_keystore:

–![]() Certificate signed by Utility PKI for FND (with private key)

Certificate signed by Utility PKI for FND (with private key)

–![]() Public Certificate of the Utility PKI CA server

Public Certificate of the Utility PKI CA server

–![]() Public Certificate of the Cisco SUDI CA

Public Certificate of the Cisco SUDI CA

■![]() Hostname must be consistent with the certificate.

Hostname must be consistent with the certificate.

■![]() No unreachable name servers in /etc/resolv.conf should exist.

No unreachable name servers in /etc/resolv.conf should exist.

■![]() NTP daemon should be running. Time should be synchronized.

NTP daemon should be running. Time should be synchronized.

■![]() Necessary firewall ports must have been opened up if the firewall/iptables/ip6tables are enabled:

Necessary firewall ports must have been opened up if the firewall/iptables/ip6tables are enabled:

–![]() TCP Port 9125 to process http communication

TCP Port 9125 to process http communication

–![]() TCP port 9120 to process https communication

TCP port 9120 to process https communication

TPS/FND FQDN entry in the /etc/hosts file:

[root@tps-san ~]#

FND must have three certificates installed into the cgms_keystore:

■![]() The certificate entry 'root' represents the Utility PKI CA certificate.

The certificate entry 'root' represents the Utility PKI CA certificate.

■![]() The certificate entry 'sudi' represents the Cisco SUDI CA certificate.

The certificate entry 'sudi' represents the Cisco SUDI CA certificate.

■![]() The certificate entry 'cgms' represents the private certificate of the FND server signed by the (custom) Utility PKI CA server.

The certificate entry 'cgms' represents the private certificate of the FND server signed by the (custom) Utility PKI CA server.

Hostname should match the certificate Common Name/SAN:

No unreachable name servers should exist. Either the name servers should be present and reachable or they should be empty. Any unreachable name server address entry must be taken care or removed under the network interface configuration:

NTP daemon should be running. Time should be synchronized:

Note: The FND server should be time synchronized. Otherwise, the https communication from the IoT Gateway might not reach the FND (cgms) application.

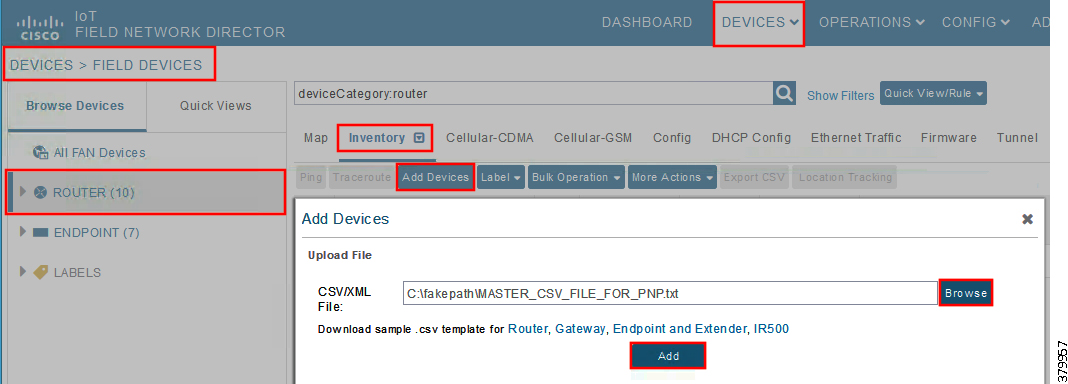

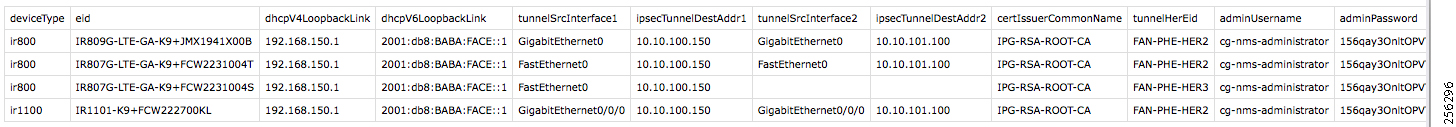

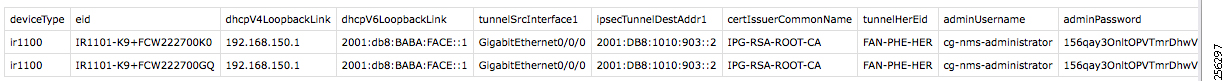

A sample csv file that can be imported into FND for bootstrapping of IoT Gateway is shown below:

Obtain the <encrypted_pwd> for the adminPassword field using the following step (from FND Linux shell prompt):

/opt/cgms-tools/bin/signature-tool encrypt /opt/cgms/server/cgms/conf/cgms_keystore password-file.txt

For more details, please refer to the following URL:

■![]() https://www.cisco.com/c/en/us/support/docs/cloud-systems-management/iot-field-network-director/210446-Prepare-csv-Comma-Separated-Value-fil.html

https://www.cisco.com/c/en/us/support/docs/cloud-systems-management/iot-field-network-director/210446-Prepare-csv-Comma-Separated-Value-fil.html

Figure 8 Bootstrapping CSV Import at Bootstrapping FND

In bootstrapping FND, from Devices > Field Devices, click Router in the left pane, click the Inventory tab on the middle pane, click Add Devices, browse the csv file created in the previous step, and then click Add to import the IoT Gateway CSV list into the bootstrapping FND.

PnP Server Discovery through DHCP and Bootstrapping

This section is discussed in the following phases:

■![]() Bootstrapping in the IPv4 Network

Bootstrapping in the IPv4 Network

Prerequisites

PnP Proxy must be reachable either over the LAN or over the WAN/Internet. As TPS is used in this implementation, TPS acts as the PnP server for the IoT Gateways. The DHCP server advertises TPS details in place of the PnP server details.

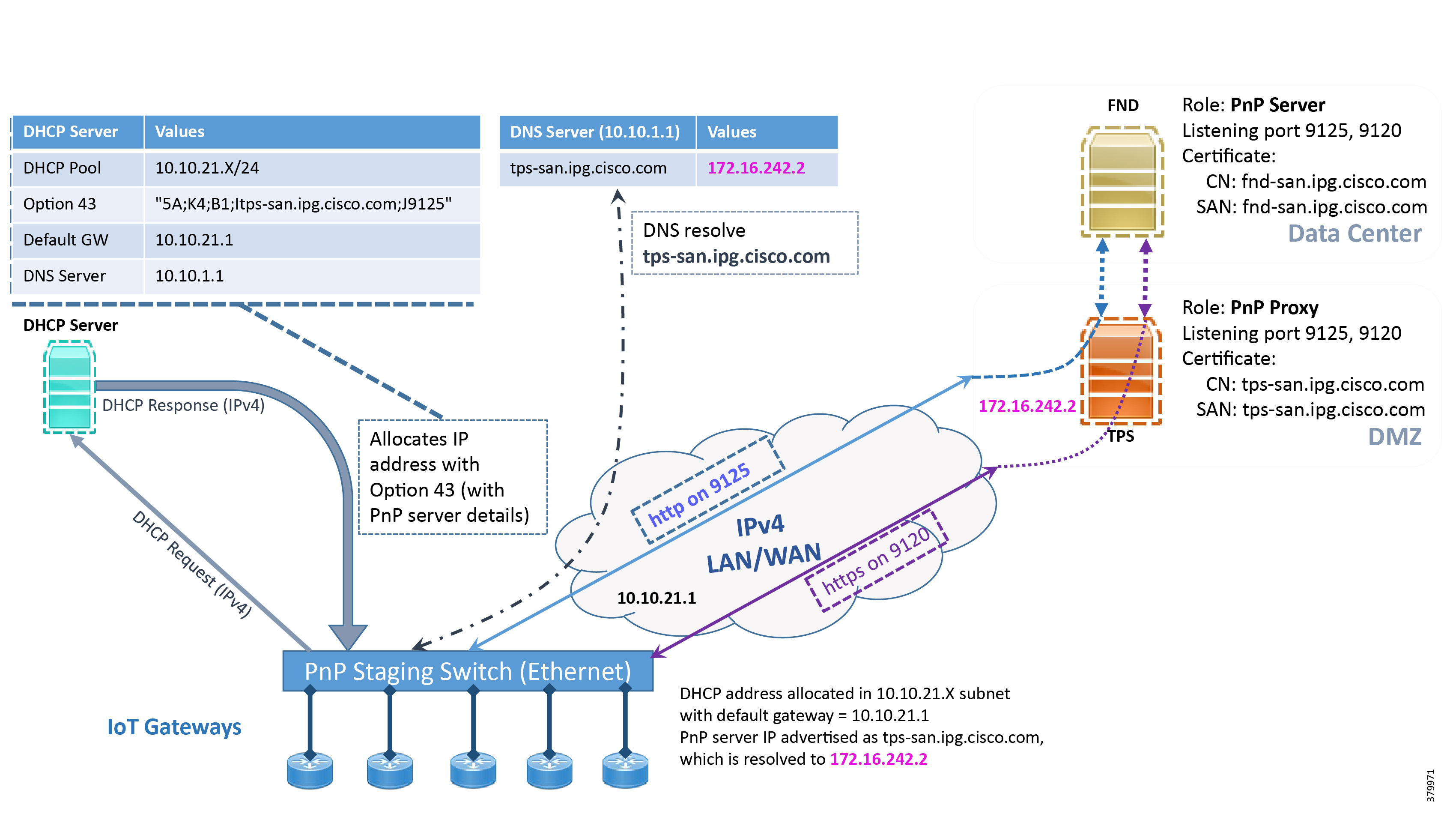

Bootstrapping in the IPv4 Network

This section discusses the DHCP server-assisted bootstrapping of the IoT Gateways over the IPv4 network.

In Figure 9, IoT Gateways obtain the IP address dynamically from the DHCP server along with details of the PnP server (which, in this case, is actually that of PnP Proxy, as TPS is deployed).

■![]() The PnP server details are received using DHCP option 43.

The PnP server details are received using DHCP option 43.

■![]() The PnP agent (residing on the IoT Gateway) then reaches out to PnP Proxy over IPv4 LAN/WAN network over http on port 9125 and then over https on port 9120.

The PnP agent (residing on the IoT Gateway) then reaches out to PnP Proxy over IPv4 LAN/WAN network over http on port 9125 and then over https on port 9120.

Figure 9 DHCP Server-Assisted Bootstrapping of IoT Gateways over IPv4 Network

Bootstrapping in the IPv6 Network

This section discusses the DHCP server-assisted bootstrapping of the IoT Gateways over the IPv6 network.

In Figure 10:

■![]() IoT Gateways obtains the IP address dynamically from the DHCP server along with details of the PnP server (which, in this case, is actually that of PnP Proxy, as TPS is deployed).

IoT Gateways obtains the IP address dynamically from the DHCP server along with details of the PnP server (which, in this case, is actually that of PnP Proxy, as TPS is deployed).

■![]() The PnP server details are received using DHCP option 9.

The PnP server details are received using DHCP option 9.

■![]() The PnP agent (residing on the IoT Gateway) then reaches out to PnP Proxy over IPv6 LAN/WAN network over http on port 9125 and then over https on port 9120.

The PnP agent (residing on the IoT Gateway) then reaches out to PnP Proxy over IPv6 LAN/WAN network over http on port 9125 and then over https on port 9120.

Figure 10 DHCP Server-Assisted Bootstrapping of IoT Gateways over IPv6 Network

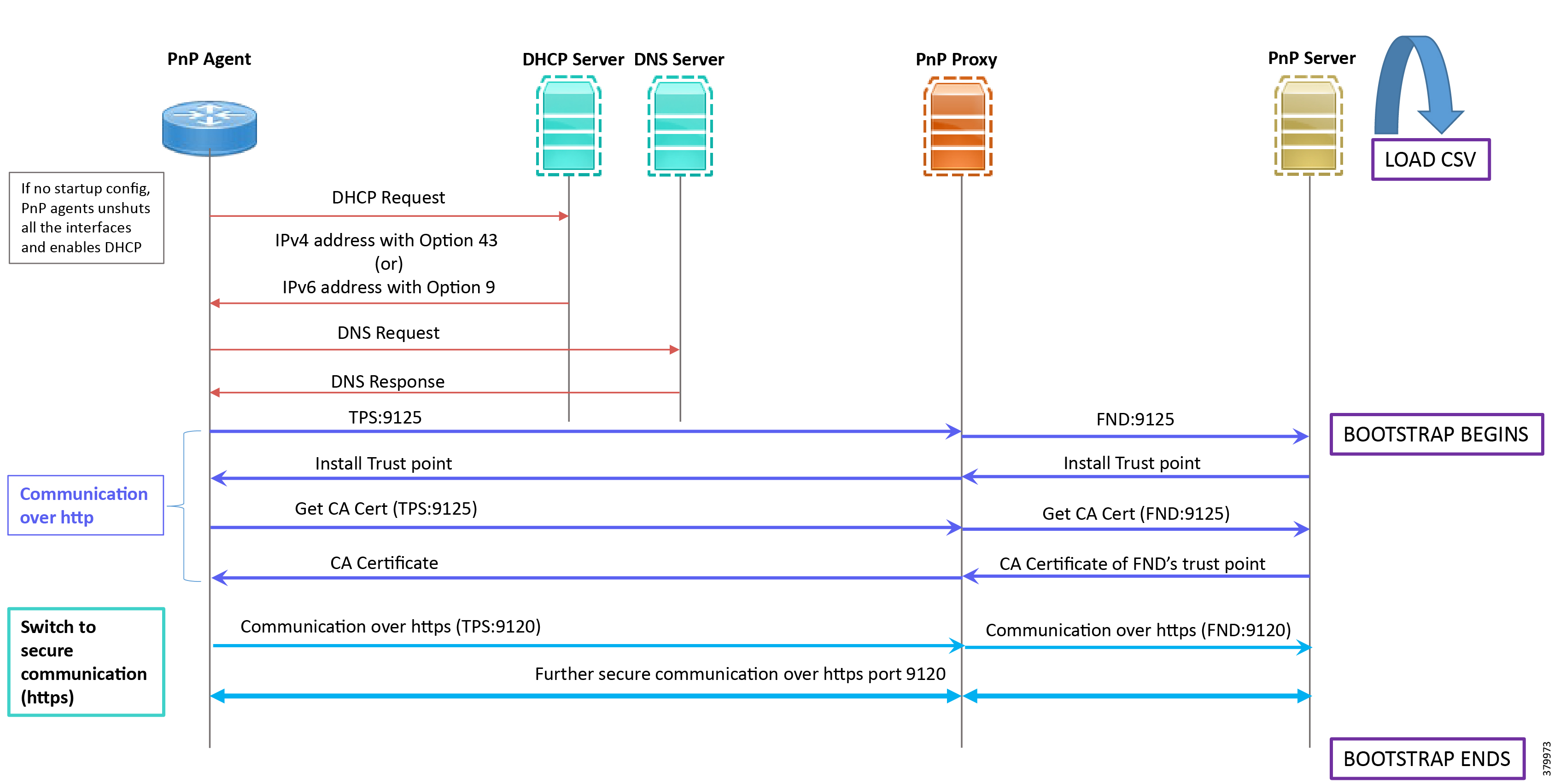

Logical Call Flow

This section discusses the logical call flow sequence with the DHCP server-assisted bootstrapping of the IoT Gateways over the IPv4/IPv6 network.

The actors shown in Figure 10 are the following:

Figure 11 DHCP Server-Assisted Bootstrapping of IoT Gateways—Logical Call Flow

1.![]() When the IoT Gateway is powered on, the PnP Agent on the IoT Gateway checks for the presence of the startup configuration. If the startup configuration is not found, then the PnP agent performs “no shut” on all the interfaces and enables DHCP on all of them.

When the IoT Gateway is powered on, the PnP Agent on the IoT Gateway checks for the presence of the startup configuration. If the startup configuration is not found, then the PnP agent performs “no shut” on all the interfaces and enables DHCP on all of them.

2.![]() The IOS on the IoT Gateway sends out a DHCP request, which reaches the DHCP server (either directly or with the help of DHCP relay agent).

The IOS on the IoT Gateway sends out a DHCP request, which reaches the DHCP server (either directly or with the help of DHCP relay agent).

3.![]() The DHCP server responds back with the IPv4 address along with option 43, or the IPv6 address along with option 9. The option contains the FQDN of the PnP server to talk to (for example, tps-san.ipg.cisco.com) and the port number (for example, 9125) on which the PnP Proxy/Server is expected to be listening. The PnP server detail advertised as part of the DHCP option is the IP address of the PnP Proxy instead of the actual PnP server (with TPS deployed as part of the solution).

The DHCP server responds back with the IPv4 address along with option 43, or the IPv6 address along with option 9. The option contains the FQDN of the PnP server to talk to (for example, tps-san.ipg.cisco.com) and the port number (for example, 9125) on which the PnP Proxy/Server is expected to be listening. The PnP server detail advertised as part of the DHCP option is the IP address of the PnP Proxy instead of the actual PnP server (with TPS deployed as part of the solution).

4.![]() The IoT Gateway then sends out a name resolution request to DNS server to resolve the FQDN to its corresponding IPv4/IPv6 address.

The IoT Gateway then sends out a name resolution request to DNS server to resolve the FQDN to its corresponding IPv4/IPv6 address.

5.![]() The PnP Agent attempts its communication with the PnP Proxy over port 9125 (over http). PnP Proxy, in turn, communicates with the FND on port 9125. Bootstrapping begins at the FND from this point. The prerequisite to processing this bootstrapping request from the IoT Gateway is the addition of IoT Gateway details into the FND with the loading of the csv file, and placing the IoT gateway under the respective “Tunnel Group” on FND (which contains the bootstrapping template under the Router Bootstrap Configuration tab).

The PnP Agent attempts its communication with the PnP Proxy over port 9125 (over http). PnP Proxy, in turn, communicates with the FND on port 9125. Bootstrapping begins at the FND from this point. The prerequisite to processing this bootstrapping request from the IoT Gateway is the addition of IoT Gateway details into the FND with the loading of the csv file, and placing the IoT gateway under the respective “Tunnel Group” on FND (which contains the bootstrapping template under the Router Bootstrap Configuration tab).

6.![]() The FND installs the trust point on the IoT Gateway.

The FND installs the trust point on the IoT Gateway.

7.![]() The IoT Gateway sends out a Get CA Certificate request to PnP Proxy, which, in turn, proxies the communication to the FND. The FND would respond back with the CA certificate of the FND's trust point, which would then be installed on the IoT Gateway.

The IoT Gateway sends out a Get CA Certificate request to PnP Proxy, which, in turn, proxies the communication to the FND. The FND would respond back with the CA certificate of the FND's trust point, which would then be installed on the IoT Gateway.

The following PnP States would have transitioned at the FND:

8.![]() From this point onwards, the further communication switches over to https on port 9120. The IoT Gateway would communicate with the TPS IP on port 9120, which, in turn, is sent to the FND IP on port 9120. The rest of the IoT Gateway bootstrapping happens over this secure https communication established on port 9120.

From this point onwards, the further communication switches over to https on port 9120. The IoT Gateway would communicate with the TPS IP on port 9120, which, in turn, is sent to the FND IP on port 9120. The rest of the IoT Gateway bootstrapping happens over this secure https communication established on port 9120.

Note: Since the communication is over https, time synchronization and certificate parameters matching must be addressed:

–![]() For example, if https://<TPS_FQDN>:9120 is attempted, then the certificate installed on the TPS must have CN/SAN configured with <TPS_FQDN>.

For example, if https://<TPS_FQDN>:9120 is attempted, then the certificate installed on the TPS must have CN/SAN configured with <TPS_FQDN>.

–![]() Similarly, if the https://<TPS_IP>:9120 is attempted, then the certificate installed on the TPS must also have CN/SAN configured with <TPS_IP>. Otherwise, SSL failure might occur and the https message from IoT Gateway might not reach the TPS Proxy Application on port 9120.

Similarly, if the https://<TPS_IP>:9120 is attempted, then the certificate installed on the TPS must also have CN/SAN configured with <TPS_IP>. Otherwise, SSL failure might occur and the https message from IoT Gateway might not reach the TPS Proxy Application on port 9120.

FND would transition through the following PnP states while the bootstrapping progresses:

–![]() PUSHING_BOOTSTRAP_CONFIG_FILE

PUSHING_BOOTSTRAP_CONFIG_FILE

–![]() PUSHING_BOOTSTRAP_CONFIG_VERIFY_HASH

PUSHING_BOOTSTRAP_CONFIG_VERIFY_HASH

9.![]() Bootstrapping would be complete with the “BOOTSTRAP_DONE” PnP State.

Bootstrapping would be complete with the “BOOTSTRAP_DONE” PnP State.

PnP Server Definition through Manual PnP Profile and Bootstrapping

This section is discussed in the following phases:

■![]() Bootstrapping over IPv4 Network

Bootstrapping over IPv4 Network

■![]() Bootstrapping over IPv6 Network

Bootstrapping over IPv6 Network

As a gateway of last resort, if dynamic ways of learning the PnP Server are not an option, an option does exist to enable learning about the PnP server with minimal manual configuration.

Manual PnP profile configuration with PnP server details:

Note: Only the PnP Server detail is manually configured. Bootstrapping and Deployment (the rest of ZTD) still happens dynamically.

Prerequisites

■![]() The PnP server must be reachable either over the LAN or over the WAN/Internet.

The PnP server must be reachable either over the LAN or over the WAN/Internet.

■![]() As TPS is used in this implementation, TPS acts as a PnP server for the IoT Gateways.

As TPS is used in this implementation, TPS acts as a PnP server for the IoT Gateways.

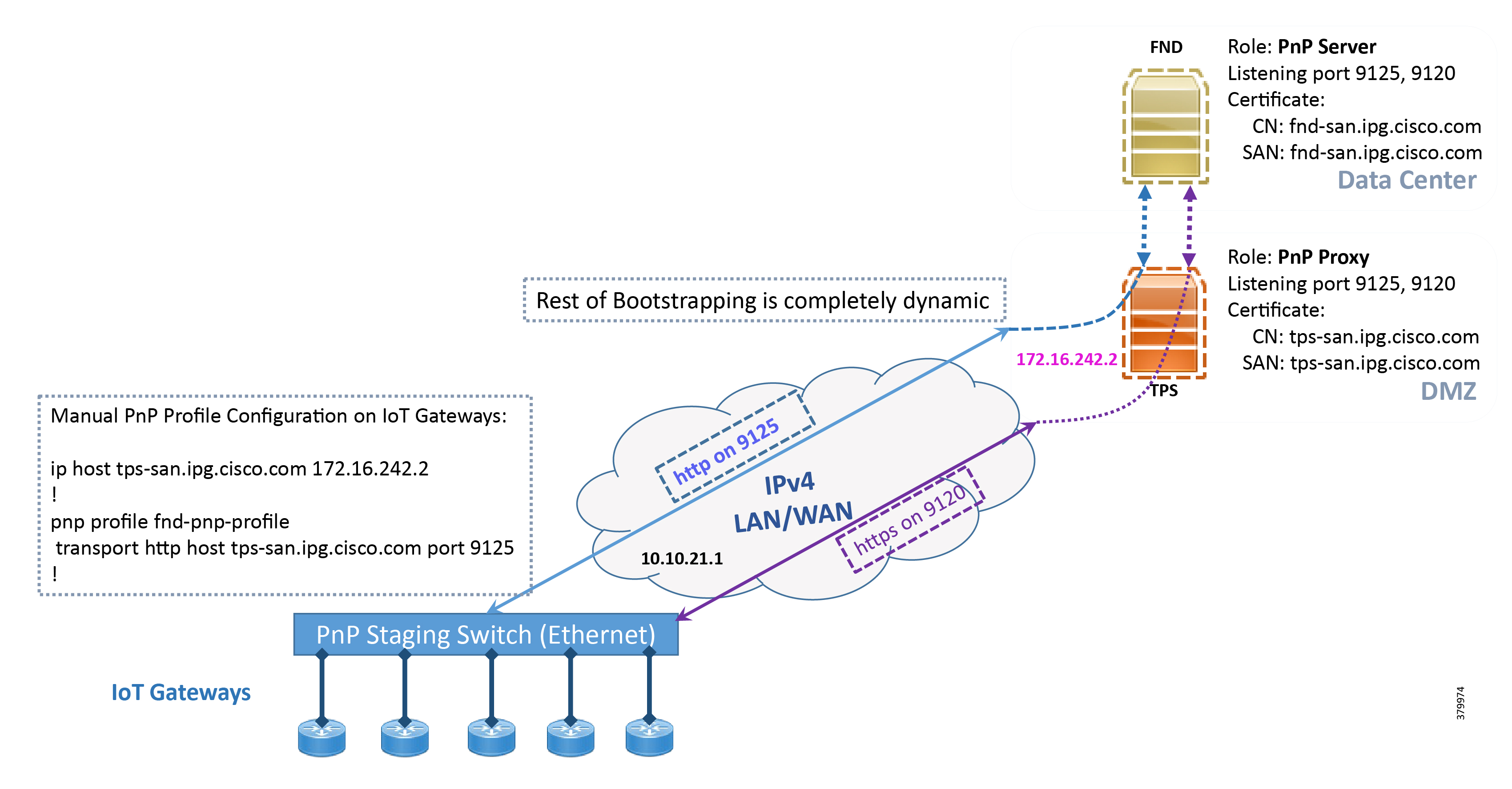

Bootstrapping over IPv4 Network

This section focuses on the bootstrapping of the IoT Gateways over the IPv4 network in the absence of the DHCP server, DNS server, and Cisco Cloud redirector server to provide the PnP server details. IoT Gateways are informed about the PnP server detail directly through the Cisco IOS configuration commands.

In Figure 12, the manual PnP profile configuration on the IoT Gateways lets the IoT Gateways learn about the PnP server that should be reached out to and the desired PnP port number. For example, the custom PnP profile is configured to reach out to the PnP server ( tps-san.ipg.cisco.com) over the http on port 9125.

Figure 12 Custom PnP Profile-Assisted Bootstrapping of IoT Gateways over IPv4 Network

Based on the manual PnP profile configuration on the IoT Gateways, communication is initially established with PnP Proxy on http://tps-san.ipg.cisco.com:9125. Later, the communication is established with the PnP Proxy on https://tps-san.ipg.cisco.com:9120.

Note: Only the PnP server discovery is made manual. The rest of the bootstrapping procedure is the same as the DHCP server-assisted PnP provisioning discussed above.

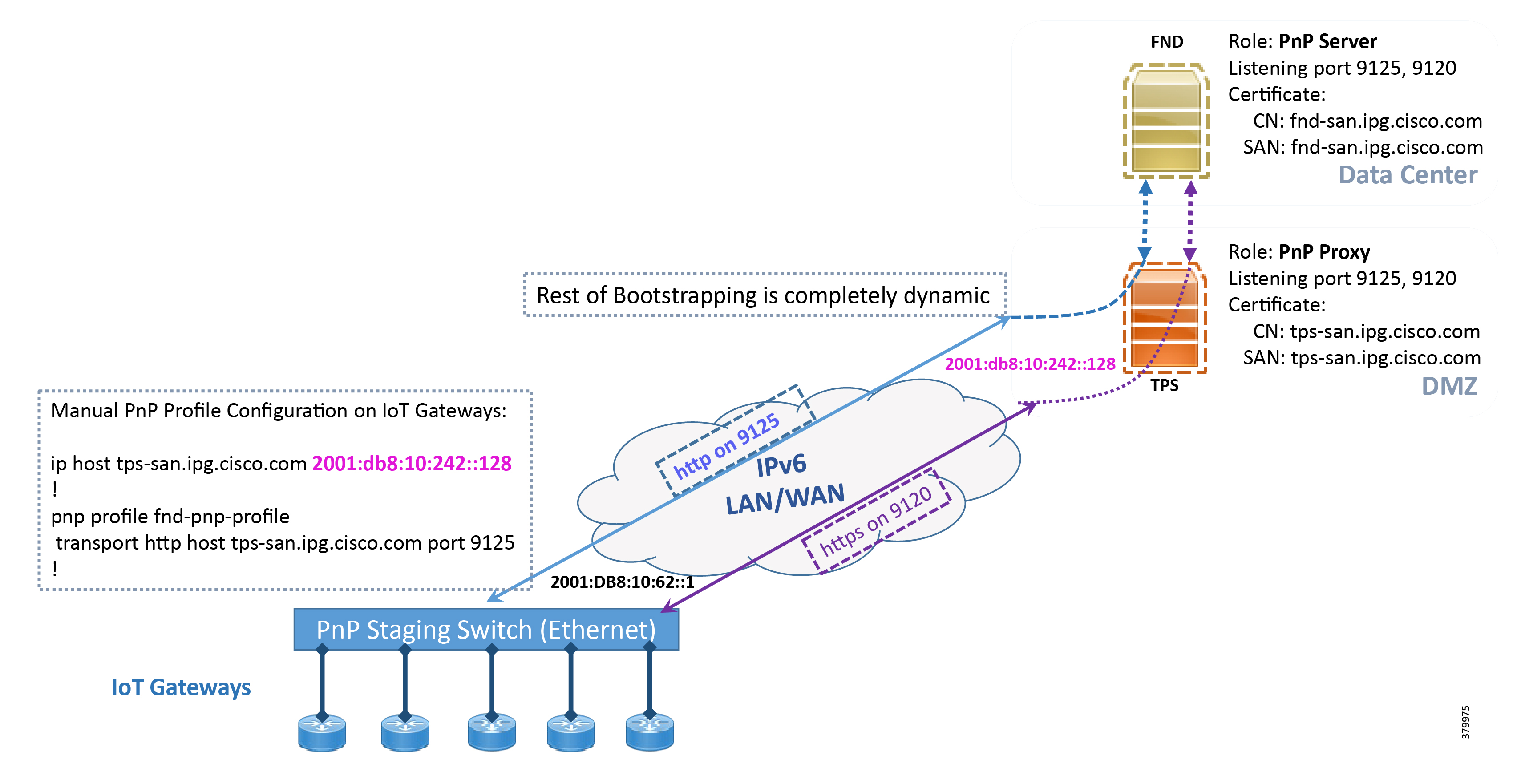

Bootstrapping over IPv6 Network

This section focuses on the bootstrapping of the IoT Gateways over the IPv6 network in the absence of the DHCP server, DNS server, and Cisco Cloud Redirector Server to provide the PnP server details. IoT Gateways are informed about the PnP server detail directly through the Cisco IOS configuration commands in order to enable bootstrapping of the IoT Gateways over the IPv6 network.

In Figure 13, based on the manual PNP profile configuration on the IoT Gateways, initially communication is established with the PnP Proxy on http://tps-san.ipg.cisco.com:9125. Later, the communication is established with PnP Proxy on https://tps-san.ipg.cisco.com:9120.

Name resolution happens to an IPv6 address, and the bootstrapping happens over an IPv6 network.

Note: Only the PnP server discovery is made manual. The rest of the bootstrapping procedure (PnP communication on port 9120 and 9125) is still dynamic.

Figure 13 Custom PnP Profile-Assisted Bootstrapping of IoT Gateways over IPv6 Network

Logical Call Flow

This section discusses the logical call flow sequence with the Custom PnP profile-assisted bootstrapping of the IoT Gateways over the IPv4/IPv6 network.

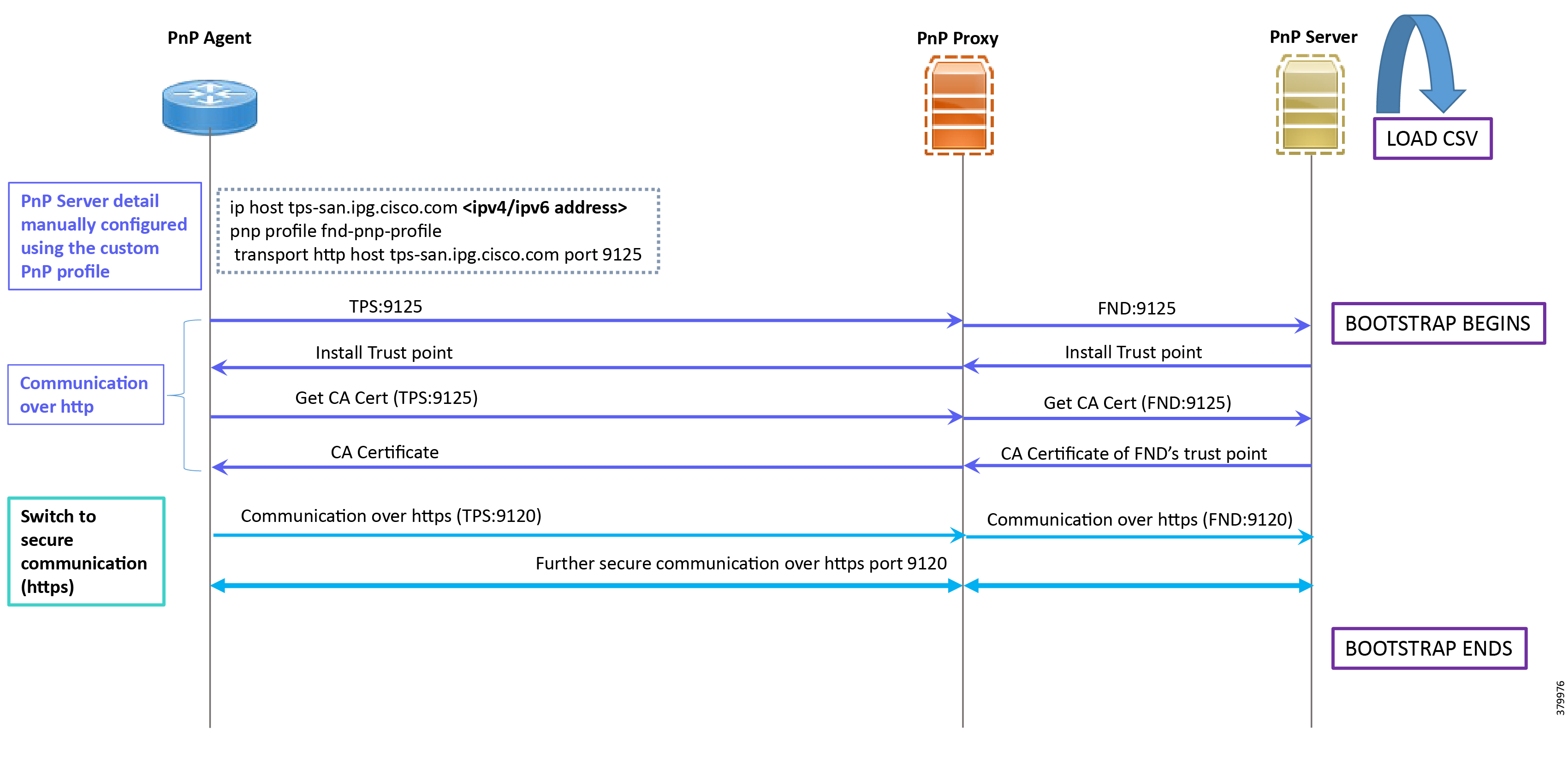

Figure 14 Custom PnP Profile-Assisted Bootstrapping of IoT Gateways—Logical Call Flow

In Figure 14:

■![]() PnP server detail is learned out of the custom PnP profile, configured manually.

PnP server detail is learned out of the custom PnP profile, configured manually.

■![]() The IoT Gateway reaches out to the PnP server in the configuration, which is http://tps- san.ipg.cisco.com:9125.

The IoT Gateway reaches out to the PnP server in the configuration, which is http://tps- san.ipg.cisco.com:9125.

■![]() The communication reaches TPS, and is then sent to FND. Bootstrapping of the IoT Gateway begins at the FND.

The communication reaches TPS, and is then sent to FND. Bootstrapping of the IoT Gateway begins at the FND.

■![]() The rest of the procedure is exactly the same as the bootstrapping steps discussed as part of DHCP server-assisted PnP Provisioning:

The rest of the procedure is exactly the same as the bootstrapping steps discussed as part of DHCP server-assisted PnP Provisioning:

–![]() Initial communication happens on http://tps-san.ipg.cisco.com:9125

Initial communication happens on http://tps-san.ipg.cisco.com:9125

–![]() Later communication happens on https://tps-san.ipg.cisco.com:9120

Later communication happens on https://tps-san.ipg.cisco.com:9120

PnP Server Discovery through Cisco PnP Connect and Bootstrapping

Prerequisites

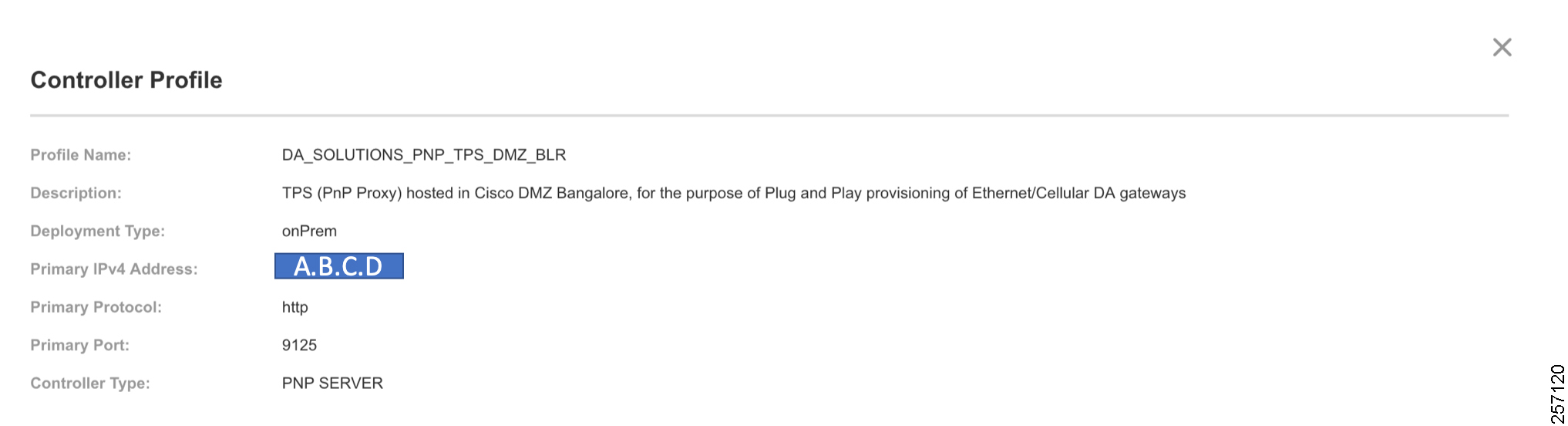

PnP Proxy must be reachable either over the WAN/Internet. As TPS is used in this implementation, TPS acts as the PnP server for the IoT Gateways. The controller profile on “software.cisco.com” should be configured with the correct TPS address. The controller profile advertises TPS details in place of the PnP server details.

To create the controller profile, login to software.cisco.com. Go to Network Plug and Play > Select controller profile from the tool bar and add the details.

Figure 15 shows the controller profile added on software.cisco.com :

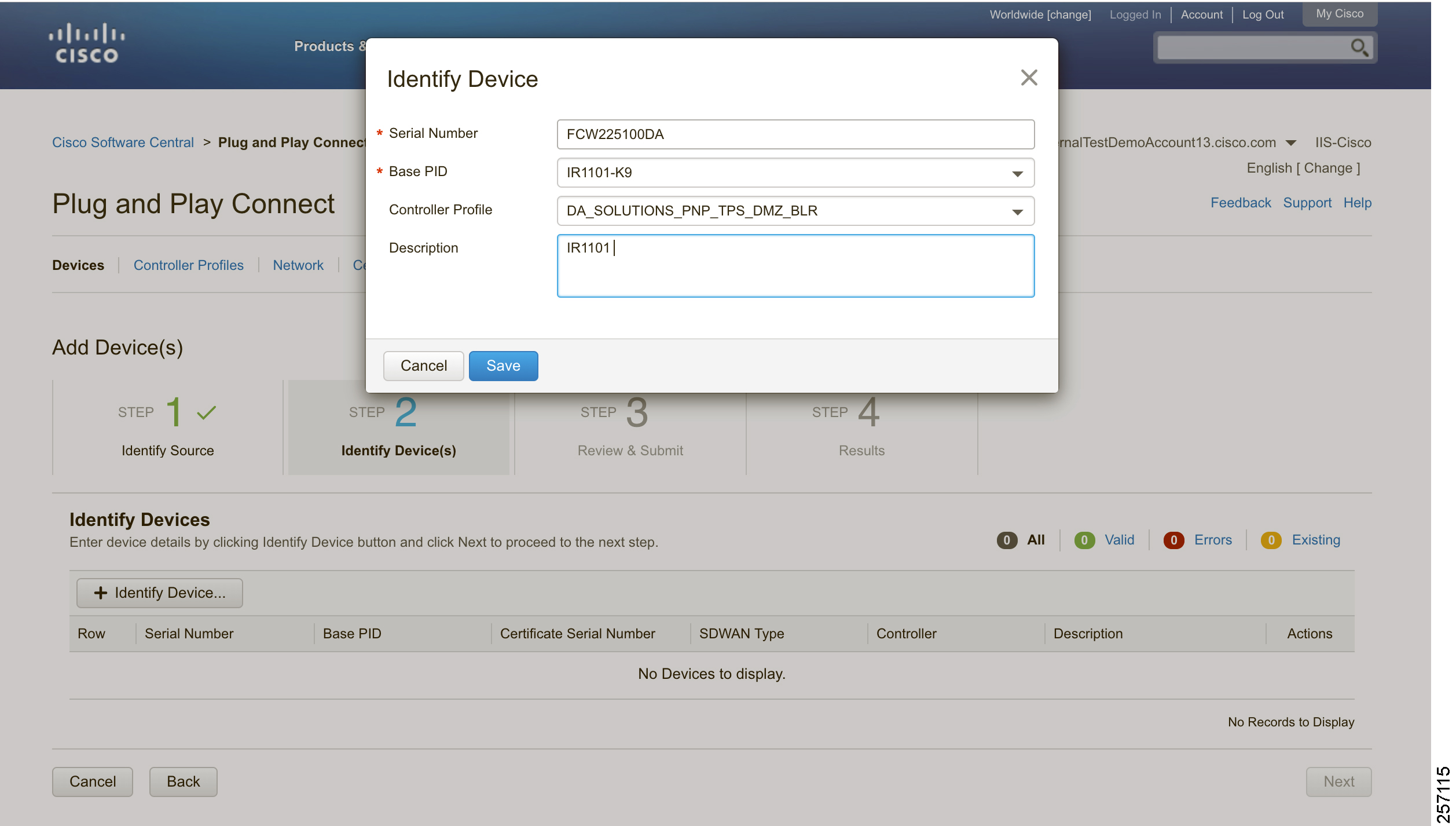

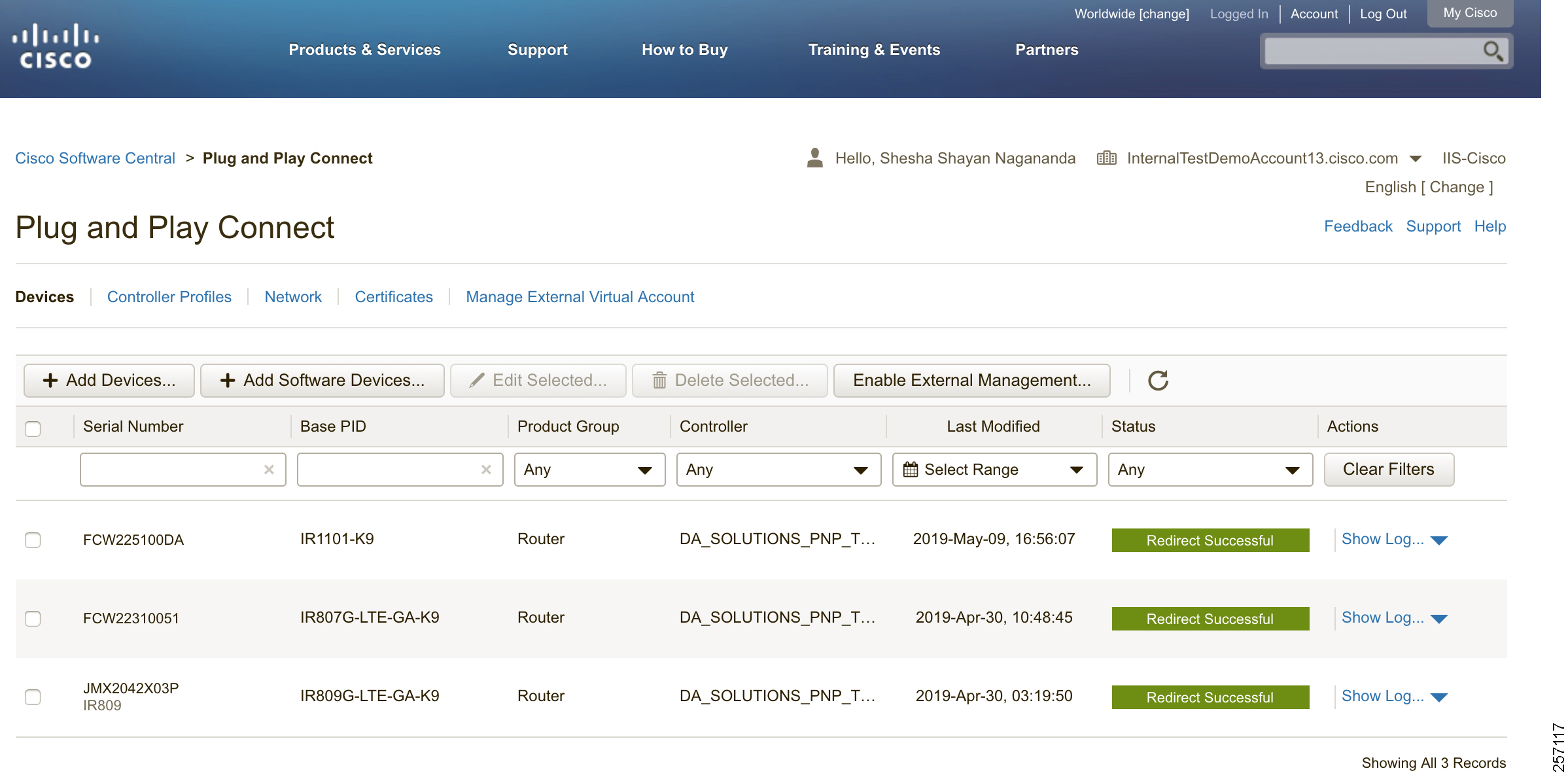

When a device is ordered through CCW, the device must be attached with the Smart account. For the PnP discovery to be successful using PnP Connect, a device must be added on the software.cisco.com portal. The device can be added either manually or by uploading a csv file. You can refer to “PnP Server Discovery Through Cisco PnP Connect” in the Cisco Distribution Automation Secondary Substation Design Guide. Figure 16 shows adding a device manually:

Figure 16 Manual Addition of Device

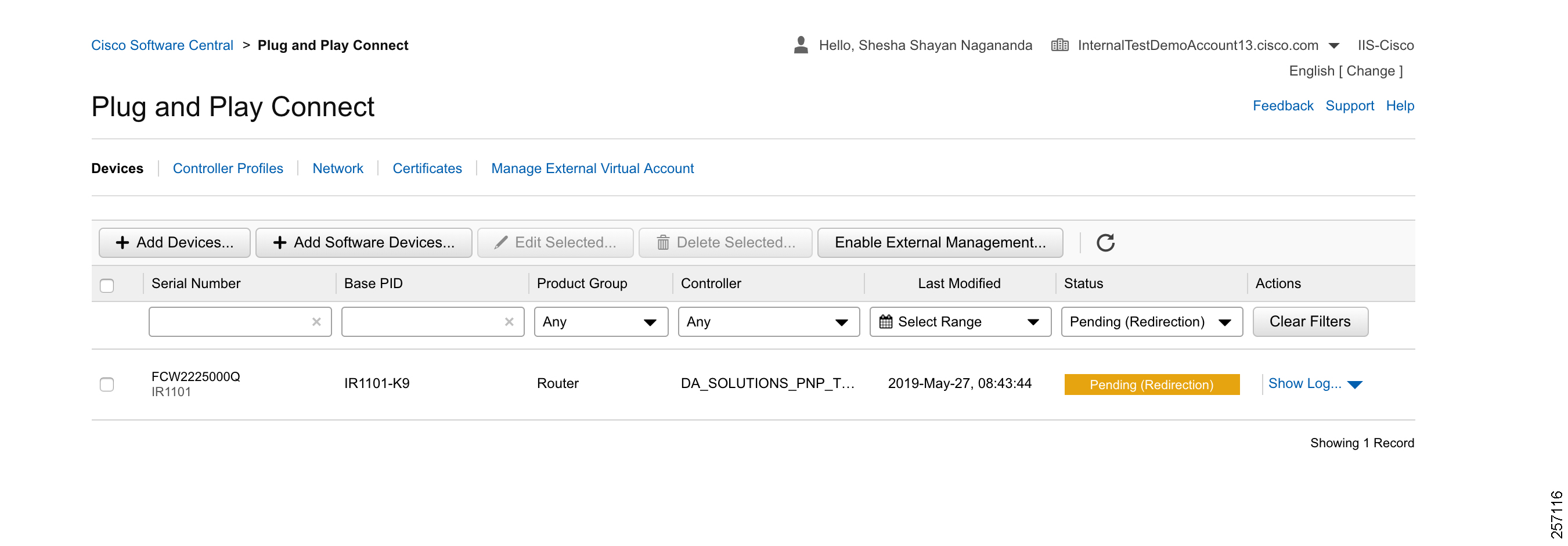

After manually adding the device in the PnP Connect portal, the request is yet to received from the device and the status for PnP redirection will be pending. This is shown in Figure 17:

Figure 17 PnP Redirect Pending after Manual Device Addition

Finally, when the device is added successfully, it should be populated in the devices list as shown in Figure 17, which lists the devices for when the Redirect was successful.

Bootstrapping

This section discusses the PnP Connect-Assisted bootstrapping of the IoT Gateways over the IPv4 network.

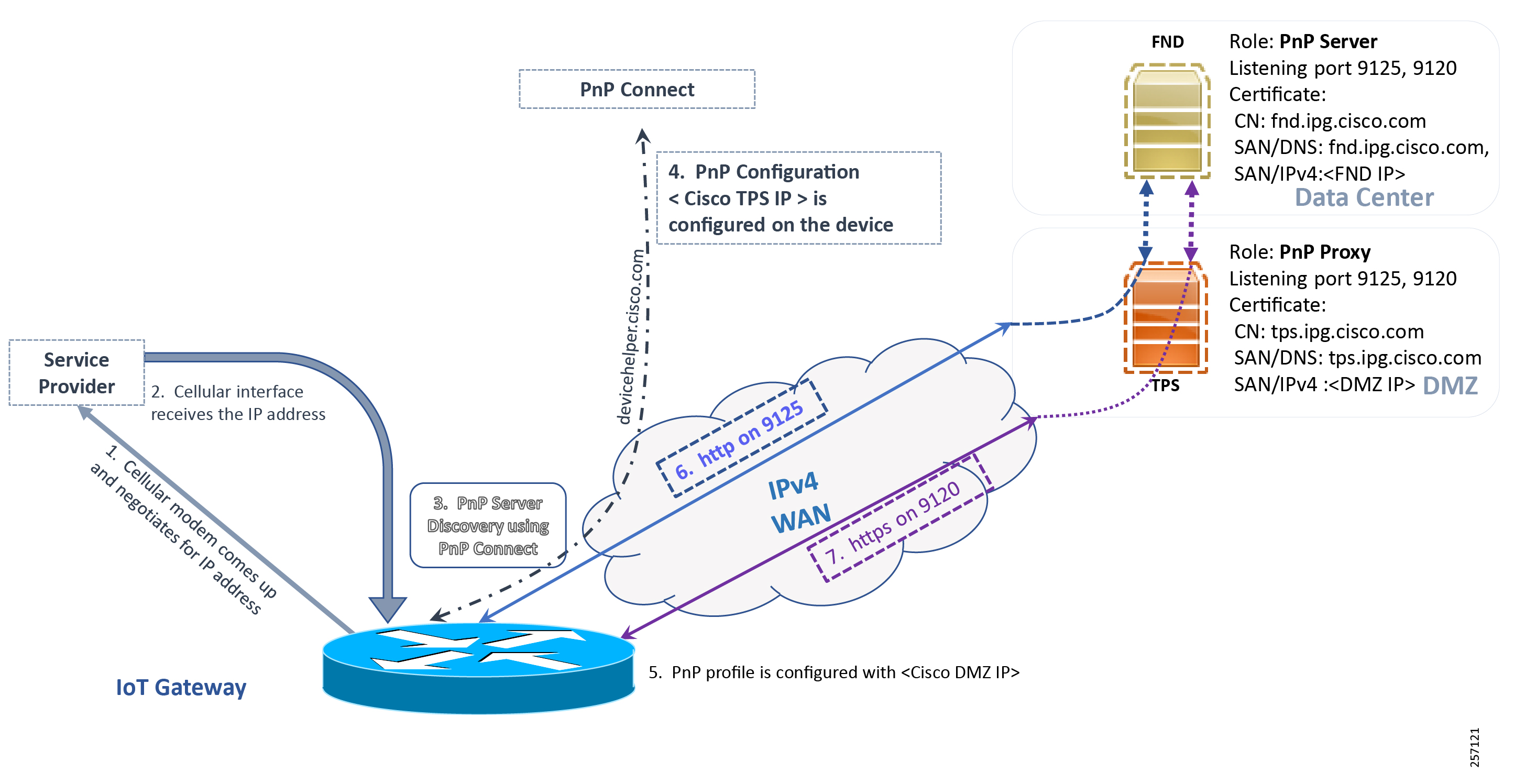

In Figure 18, IoT Gateways obtain the IP address dynamically from the service provider:

■![]() The PnP agent (residing on the IoT Gateway) then reaches out to PnP Proxy over IPv4 LAN/WAN network over http on port 9125 and then over https on port 9120.

The PnP agent (residing on the IoT Gateway) then reaches out to PnP Proxy over IPv4 LAN/WAN network over http on port 9125 and then over https on port 9120.

Figure 18 PnP Connect—Assisted Bootstrapping of IoT Gateways

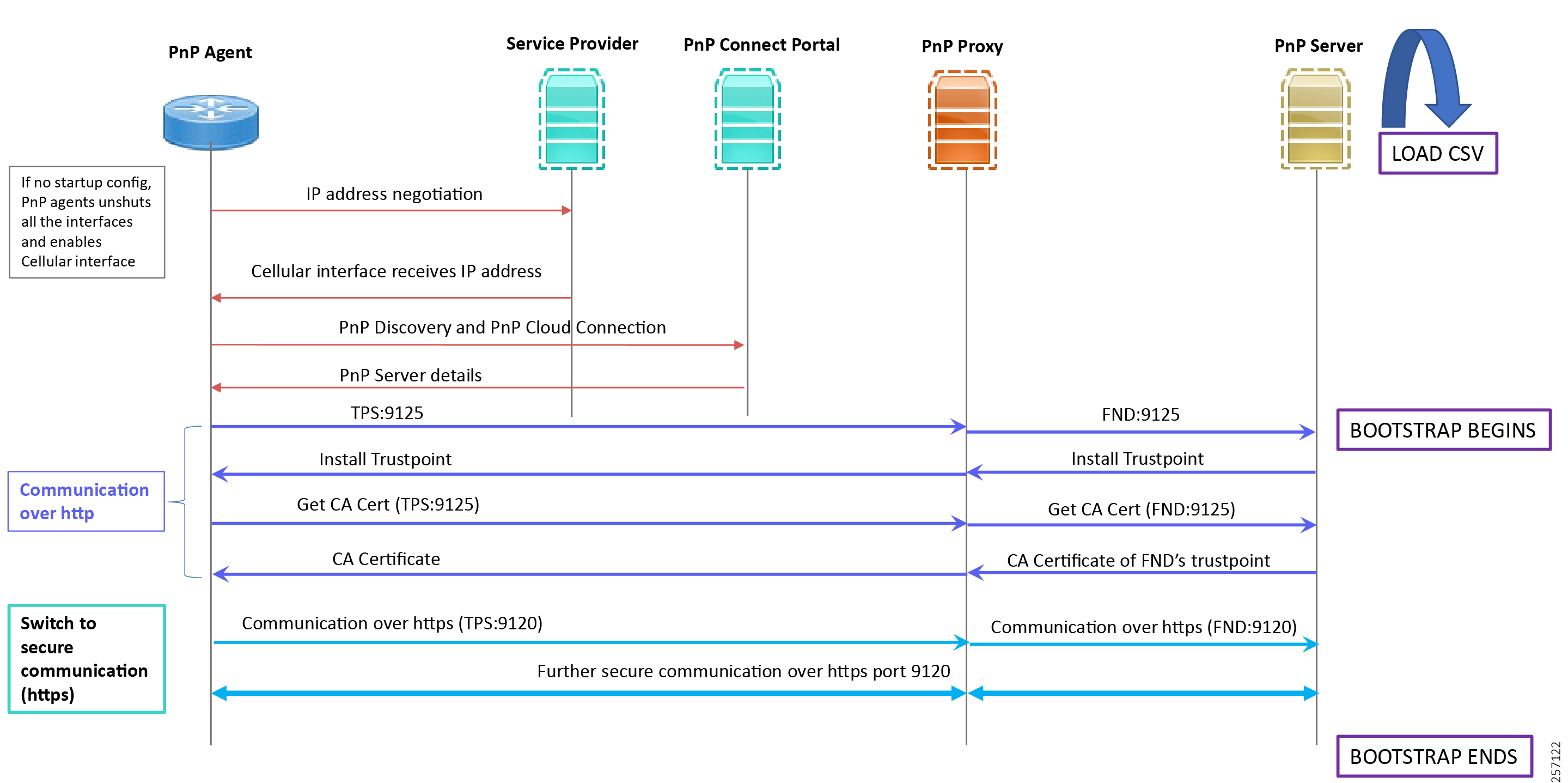

Logical Call Flow

This section discusses the logical call flow sequence with the DHCP server-assisted bootstrapping of the IoT Gateways over the IPv4/IPv6 network.

The actors shown in Figure 19 are the following:

■![]() PnP Cloud Re-direction Service PnP Connect Portal

PnP Cloud Re-direction Service PnP Connect Portal

Figure 19 PnP Connect—Assisted Bootstrapping of IoT Gateways—Logical Call Flow

1.![]() When the IoT Gateway is powered on, the PnP Agent on the IoT Gateway checks for the presence of the startup configuration. If the startup configuration is not found, then the PnP agent performs “no shut” on all the cellular interfaces.

When the IoT Gateway is powered on, the PnP Agent on the IoT Gateway checks for the presence of the startup configuration. If the startup configuration is not found, then the PnP agent performs “no shut” on all the cellular interfaces.

2.![]() The IOS on the IoT Gateway sends out a request to the service provider.

The IOS on the IoT Gateway sends out a request to the service provider.

3.![]() The service provider responds back with the IPv4 address.

The service provider responds back with the IPv4 address.

4.![]() The IOT gateway proceeds for PnP server discovery and connects to the PnP cloud re-direction service connect portal. After successfully connecting the server devicehelper.cisco.com, the server PnP Connect portal sends the publicly reachable TPS DMZ IP(A.B.C.D) PnP proxy IP and the port number (9125) on which the proxy server is listening. The serial number of the gateway should be added to the Cisco Cloud PnP Connect portal for the re-direction service to be successful. Figure 20 shows that the PnP redirection is successful.

The IOT gateway proceeds for PnP server discovery and connects to the PnP cloud re-direction service connect portal. After successfully connecting the server devicehelper.cisco.com, the server PnP Connect portal sends the publicly reachable TPS DMZ IP(A.B.C.D) PnP proxy IP and the port number (9125) on which the proxy server is listening. The serial number of the gateway should be added to the Cisco Cloud PnP Connect portal for the re-direction service to be successful. Figure 20 shows that the PnP redirection is successful.

5.![]() Once the PnP discovery is successful, the PnP profile is configured on the device with the publicly reachable TPS DMZ IP. Once the profile is configured, the bootstrapping begins.

Once the PnP discovery is successful, the PnP profile is configured on the device with the publicly reachable TPS DMZ IP. Once the profile is configured, the bootstrapping begins.

6.![]() The rest of the procedure is exactly the same as the bootstrapping steps discussed as part of PnP server discovery through DHCP server.

The rest of the procedure is exactly the same as the bootstrapping steps discussed as part of PnP server discovery through DHCP server.

Figure 20 PnP Redirection Successful

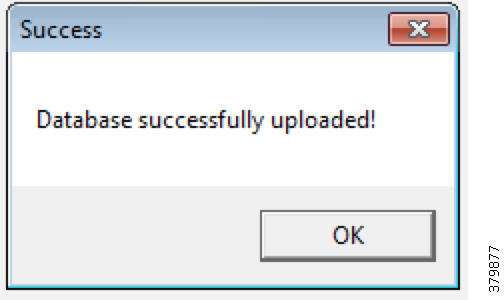

Bootstrapping Configuration Template on Bootstrapping FND

Like the tunnel provisioning template, the bootstrapping template has to be defined on FND. This template initiates the deployment process when the gateway is deployed in the desired location.

The bootstrapping template is a configuration template residing on the bootstrapping FND. As part of the bootstrapping procedure, when the bootstrapping request is received from the IoT Gateway, this bootstrap configuration template is translated into the Cisco IOS configuration, which is then pushed onto the IoT Gateway.

In the previous section, we discussed three PnP server discovery methods. In this section, we will discuss the bootstrapping template creation for enabling the gateway to undergo the deployment process without any manual intervention.

Once this Cisco IOS configuration is pushed onto the IoT Gateway and copied onto a running configuration successfully, the bootstrapping is said to be SUCCESSFUL.

This bootstrapping of Cisco IoT Gateways from Cisco IoT FND (PnP Server) is entirely Zero Touch.

This implementation section includes the following sections:

Creation of Bootstrap Configuration Template Group

This section covers the steps required for configuring the bootstrapping group.

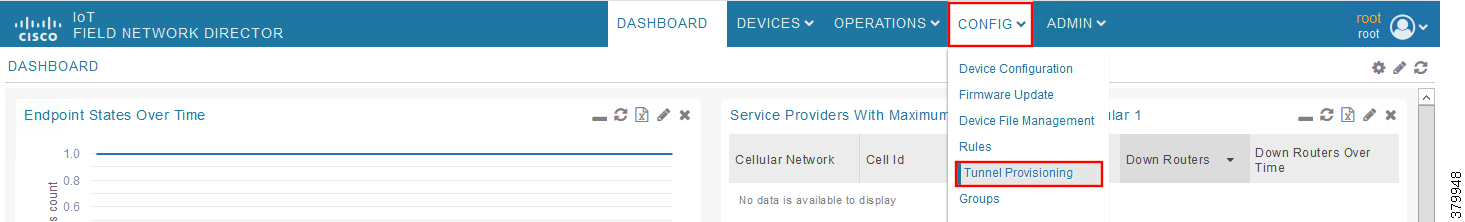

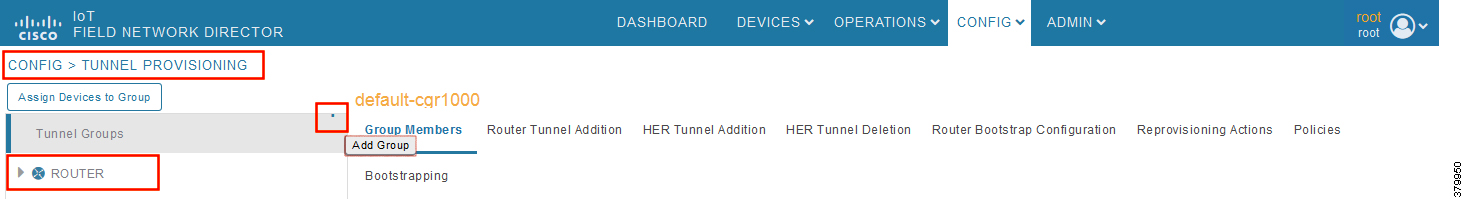

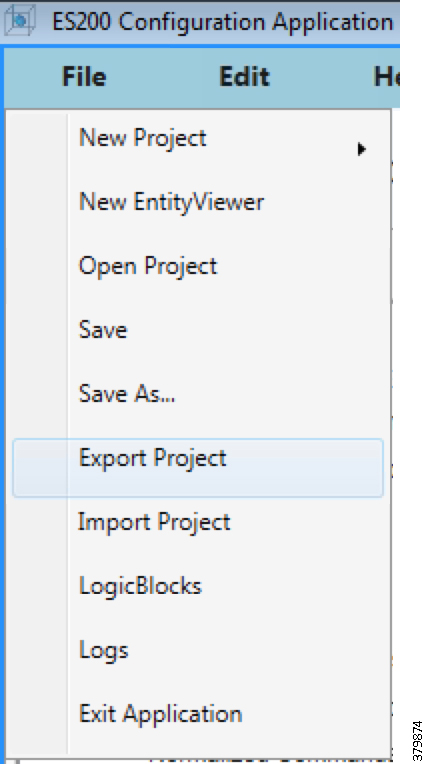

Figure 21 CREATE Bootstrap—CONFIG—Tunnel Provisioning

1.![]() From the CONFIG Menu, select the Tunnel Provisioning option.

From the CONFIG Menu, select the Tunnel Provisioning option.

Figure 22 CREATE Bootstrap—Add Group

2.![]() With the Router Group selected in the left pane, click the “+” sign (Add Group icon) located in the top right of the left pane.

With the Router Group selected in the left pane, click the “+” sign (Add Group icon) located in the top right of the left pane.

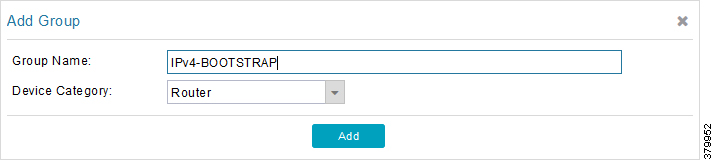

Figure 23 CREATE Bootstrap—Add IPv4 Group

3.![]() Configure the group name IPv4-BOOTSTRAP, and click Add.

Configure the group name IPv4-BOOTSTRAP, and click Add.

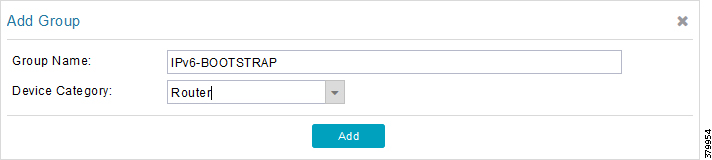

Figure 24 CREATE Bootstrap—Add IPv6 Group

4.![]() Similarly, configure another group name IPv6-BOOTSTRAP for bootstrapping over the IPv6 network. Click Add:

Similarly, configure another group name IPv6-BOOTSTRAP for bootstrapping over the IPv6 network. Click Add:

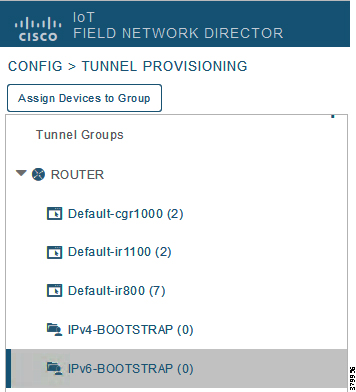

Figure 25 CREATE Bootstrap—List of Bootstrap Groups

The two newly created bootstrapping groups are displayed in the left pane:

■![]() IPv4-BOOTSTRAP (created to handle bootstrapping over the IPv4 network)

IPv4-BOOTSTRAP (created to handle bootstrapping over the IPv4 network)

■![]() IPv6-BOOTSTRAP (created to handle bootstrapping over the IPv6 network)

IPv6-BOOTSTRAP (created to handle bootstrapping over the IPv6 network)

Moving Devices under the Bootstrapping Group

Multiple bootstrapping groups could be configured on the bootstrapping FND. IoT Gateways have to be moved under the correct group in order to have it bootstrapped with the appropriate configuration.

Complete the following steps to move IoT Gateways under the correct bootstrapping group:

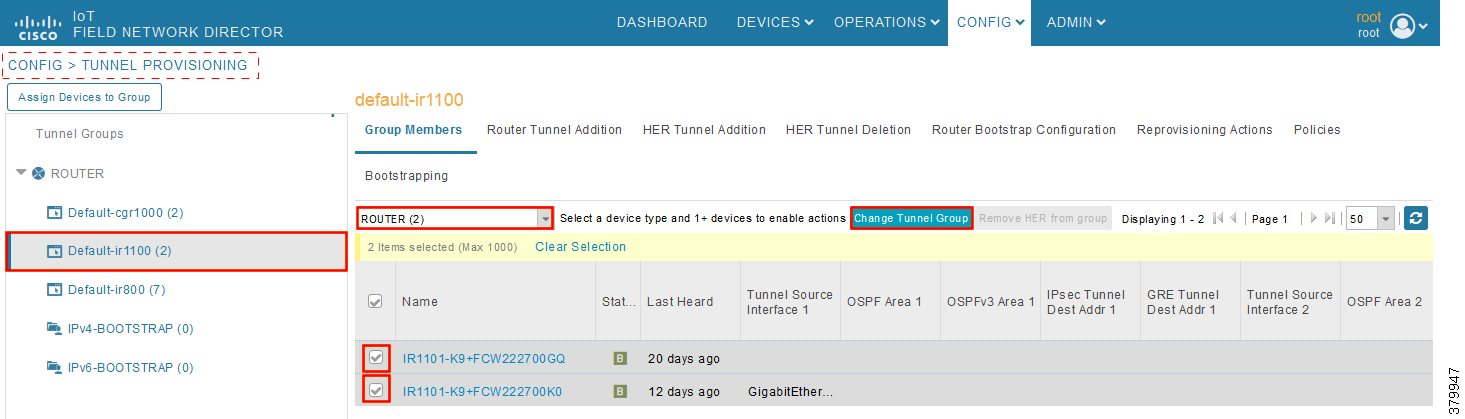

1.![]() In Figure 26, two IoT Gateways are under the default group. The devices need to be moved to the newly created IPv4-BOOTSTRAP group. In the middle pane, select the Router in the pull-down menu, select the IoT Gateways to be moved under the new bootstrapping group, and then click Change Tunnel Group.

In Figure 26, two IoT Gateways are under the default group. The devices need to be moved to the newly created IPv4-BOOTSTRAP group. In the middle pane, select the Router in the pull-down menu, select the IoT Gateways to be moved under the new bootstrapping group, and then click Change Tunnel Group.

Figure 26 CHANGE Tunnel Group—Device Under Default Group

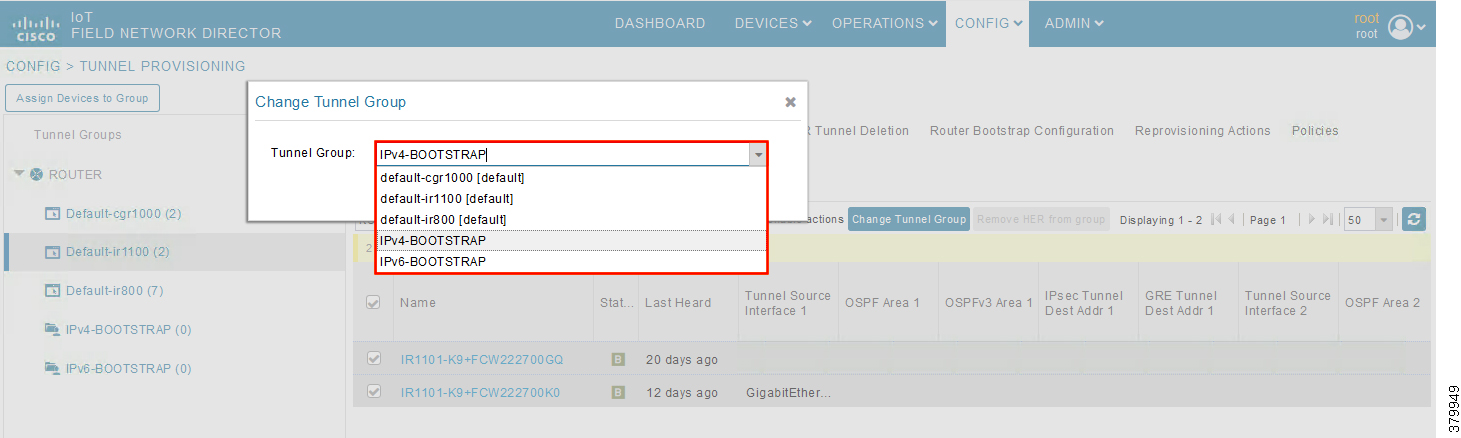

Figure 27 CHANGE Tunnel Group—Pull-Down Menu

2.![]() Choose the correct bootstrap group IPv4-BOOTSTRAP. To perform bootstrapping over the IPv6 network, choose the IPv6-BOOTSTRAP tunnel group.

Choose the correct bootstrap group IPv4-BOOTSTRAP. To perform bootstrapping over the IPv6 network, choose the IPv6-BOOTSTRAP tunnel group.

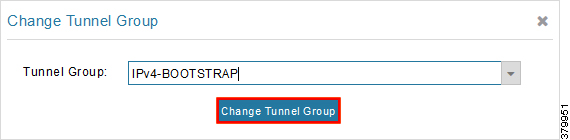

Figure 28 CHANGE Tunnel Group—Select IPv4 Group

3.![]() With the appropriate bootstrap group chosen, click Change Tunnel Group to move the IoT Gateway from the default group to the desired group.

With the appropriate bootstrap group chosen, click Change Tunnel Group to move the IoT Gateway from the default group to the desired group.

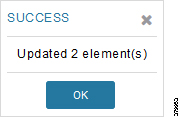

Figure 29 CHANGE Tunnel Group—Updated IPv4 Group

4.![]() Device migration to the desired group was successful.

Device migration to the desired group was successful.

Figure 30 CHANGE Tunnel Group—Devices Moved under IPv4 Group

5.![]() In Figure 30, it can be seen that IoT Gateways were moved under the correct bootstrapping group.

In Figure 30, it can be seen that IoT Gateways were moved under the correct bootstrapping group.

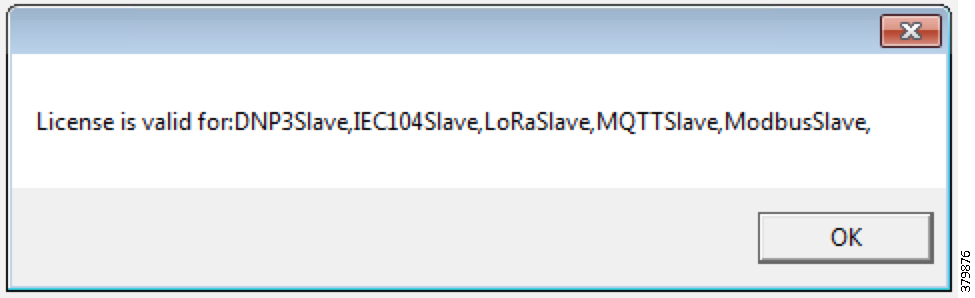

Router Bootstrap Configuration Groups—Populating Templates

This section shows where to populate the bootstrapping template in FND, and the template that needs to be chosen for bootstrapping of the IoT Gateways according to the network in which the IoT Gateway would be deployed (for example, IPv4/IPv6 network, located/not located behind NAT, etc).

Note: Working versions of bootstrapping templates can be found in Appendix A: PnP Profiles.

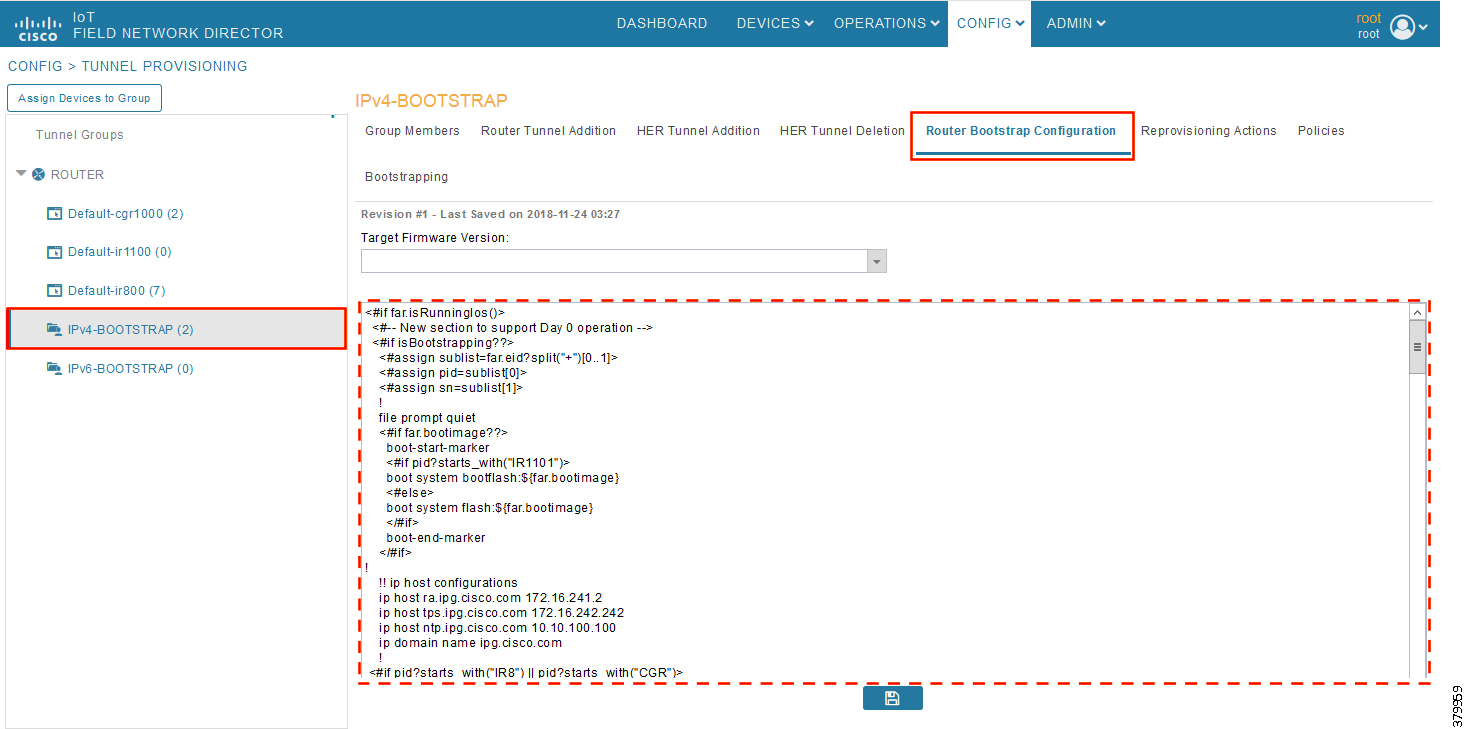

Figure 31 captures the Router Bootstrap Configuration section that needs to be populated for the purpose of bootstrapping:

Figure 31 Router Bootstrap Configuration

Every bootstrap group (referred as Tunnel Group in the left pane) can be populated with a unique Router Bootstrap configuration.

|

|

|

|

|---|---|---|

With reference to Table 11, for bootstrapping the IoT Gateways for deployment over the IPv4 network:

■![]() If IoT Gateways are located behind NAT, then the bootstrapping template IPv4-BOOTSTRAP-NAT could be used.

If IoT Gateways are located behind NAT, then the bootstrapping template IPv4-BOOTSTRAP-NAT could be used.

■![]() If IoT Gateways are not located behind NAT, then the bootstrapping template IPv4-BOOTSTRAP could be used.

If IoT Gateways are not located behind NAT, then the bootstrapping template IPv4-BOOTSTRAP could be used.

Similarly, for Bootstrapping the IoT Gateways for deployment over IPv6 network:

■![]() If IoT Gateways are located behind NAT, then the bootstrapping template IPv6-BOOTSTRAP-NAT could be used.

If IoT Gateways are located behind NAT, then the bootstrapping template IPv6-BOOTSTRAP-NAT could be used.

■![]() If IoT Gateways are not located behind NAT, then the bootstrapping template IPv6-BOOTSTRAP could be used.

If IoT Gateways are not located behind NAT, then the bootstrapping template IPv6-BOOTSTRAP could be used.

Deployment of the Cisco IoT Gateway

This section includes the following topics:

Prerequisites for Deployment

■![]() Cisco IoT Gateway should have gone through the bootstrapping procedure mentioned in Bootstrapping of the IoT Gateway, with the device being part of the appropriate bootstrapping group.

Cisco IoT Gateway should have gone through the bootstrapping procedure mentioned in Bootstrapping of the IoT Gateway, with the device being part of the appropriate bootstrapping group.

■![]() The CSV file should be imported for the IoT Gateways at the Control Center FND. Refer to Figure 171 available in Appendix B: FND Zero Touch Deployment Profiles, which shows the CSV file.

The CSV file should be imported for the IoT Gateways at the Control Center FND. Refer to Figure 171 available in Appendix B: FND Zero Touch Deployment Profiles, which shows the CSV file.

Deployment Infrastructure Readiness

■![]() Cisco IoT Gateway should be assigned an IPv4/IPv6 address dynamically over Ethernet/Cellular. If a static address needs to be used on the Cisco IoT Gateway, then assignment of address to the Cisco IoT Gateway's interface needs to be taken care as part of Bootstrapping.

Cisco IoT Gateway should be assigned an IPv4/IPv6 address dynamically over Ethernet/Cellular. If a static address needs to be used on the Cisco IoT Gateway, then assignment of address to the Cisco IoT Gateway's interface needs to be taken care as part of Bootstrapping.

■![]() Cisco Field Area Network—Headend (DSO Control Center1) should be UP and running:

Cisco Field Area Network—Headend (DSO Control Center1) should be UP and running:

–![]() If it needs to be set up, the Cisco FAN-Headend Deep Dive Implementation and FAN Use Cases' guide could be referenced to set up the headend in the DSO Control Center or NOC.

If it needs to be set up, the Cisco FAN-Headend Deep Dive Implementation and FAN Use Cases' guide could be referenced to set up the headend in the DSO Control Center or NOC.

■![]() All the required headend components like the CA server (RSA), AAA, AD, Registration Authority, NOC TPS/FND, DHCP server, and HERs are expected to be up and running in the DSO Control Center1.

All the required headend components like the CA server (RSA), AAA, AD, Registration Authority, NOC TPS/FND, DHCP server, and HERs are expected to be up and running in the DSO Control Center1.

■![]() NOC TPS, RA, and HERs must have static IP addresses configured and should be reachable from the Cisco IoT Gateways that are located in the secondary substation or along the Distribution network.

NOC TPS, RA, and HERs must have static IP addresses configured and should be reachable from the Cisco IoT Gateways that are located in the secondary substation or along the Distribution network.

Note: If the prerequisites for deployment are addressed, ZTD of the IoT Gateways should happen successfully after the gateway is deployed at the desired location and powered on, with the Ethernet cable connected or the LTE SIM card inserted.

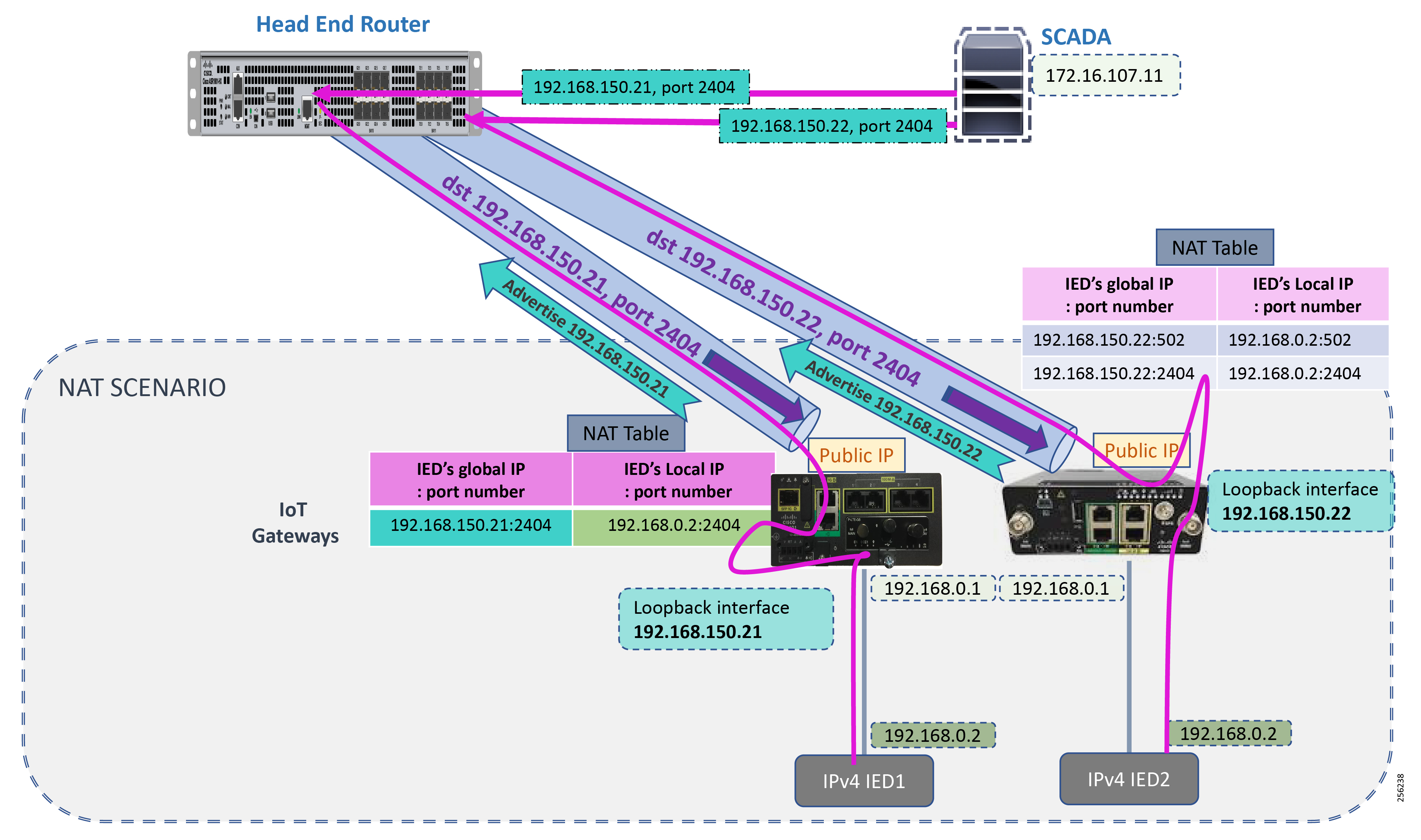

Deployment over IPv4 Cellular Network with NAT

Note: This section has no implementation steps. As the name “ZTD” states, it's a zero touch deployment. As long as bootstrapping happened successfully by having the IoT Gateway part of the correct bootstrapping group, this deployment should happen successfully with no manual steps.

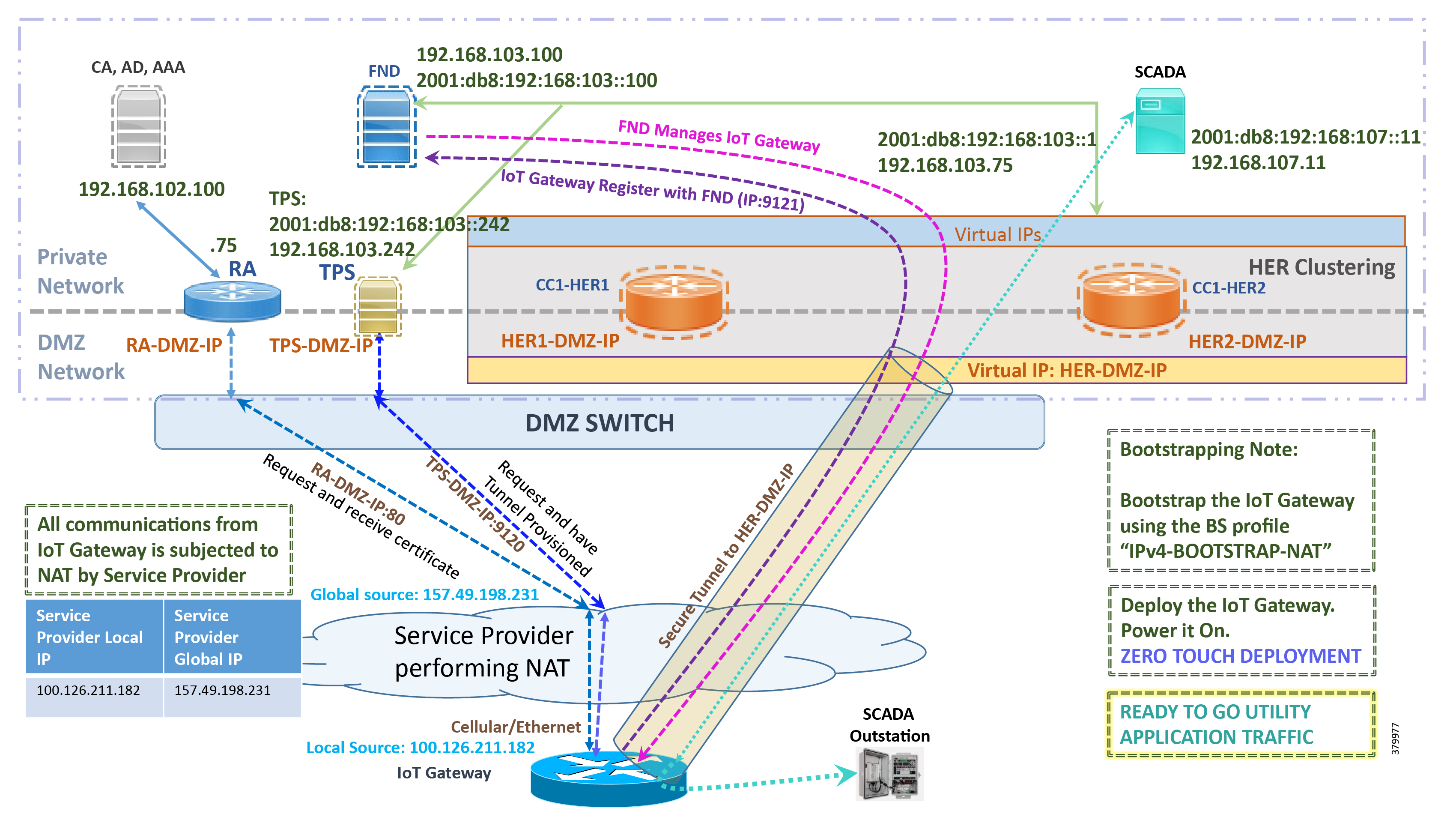

Figure 32 captures the deployment steps for IoT Gateway over LTE Cellular:

Figure 32 Deployment over IPv4 Cellular Network with Cisco DMZ Headend

Note: This scenario has been validated with the headend located in the Cisco DMZ.

The following is the summary sequence of steps that occurs during the deployment:

1.![]() The IoT Gateway is powered on. When up, it obtains the IP address over LTE Cellular interface.

The IoT Gateway is powered on. When up, it obtains the IP address over LTE Cellular interface.

2.![]() The EEM Script for ZTD kicks in and waits for the time to be synchronized. Then, SCEP enrollment happens over port 80 with RA-DMZ-IP.

The EEM Script for ZTD kicks in and waits for the time to be synchronized. Then, SCEP enrollment happens over port 80 with RA-DMZ-IP.

3.![]() Once the certificate is received for the IoT Gateway (from the RA/CA), the ZTD script disables itself and activates the CGNA profile for tunnel provisioning (cgna initiator-profile cg-nms-tunnel).

Once the certificate is received for the IoT Gateway (from the RA/CA), the ZTD script disables itself and activates the CGNA profile for tunnel provisioning (cgna initiator-profile cg-nms-tunnel).

Note: “cgna initiator-profile cg-nms-tunnel” must be used when the IoT Gateway is behind NAT, whereas “ cgna profile cg-nms-tunnel” must be used when no NAT exists between IoT Gateway and TPS. This CGNA profile is configured as part of bootstrapping.

4.![]() TPS/FND provisions the secure FlexVPN tunnel with the HER Cluster located in the DSO Control Center1.

TPS/FND provisions the secure FlexVPN tunnel with the HER Cluster located in the DSO Control Center1.

5.![]() As an overlay routing, FND and SCADA routes are advertised (by the HER) to the IoT Gateway through the secure FlexVPN tunnel.

As an overlay routing, FND and SCADA routes are advertised (by the HER) to the IoT Gateway through the secure FlexVPN tunnel.

6.![]() The IoT Gateway sends out a registration request to FND on port 9121. Once registered successfully, the IOT Gateway is remotely manageable from the FND.

The IoT Gateway sends out a registration request to FND on port 9121. Once registered successfully, the IOT Gateway is remotely manageable from the FND.

7.![]() As part of the device registration with the FND, FND also pushes SCADA Traffic enablement configurations to the IoT Gateway, which enables the communication between the SCADA Master in the Control Center and the SCADA Outstation located in the Secondary Substation/Distribution Network.

As part of the device registration with the FND, FND also pushes SCADA Traffic enablement configurations to the IoT Gateway, which enables the communication between the SCADA Master in the Control Center and the SCADA Outstation located in the Secondary Substation/Distribution Network.

Deployment over IPv4 Network without NAT

Note: This section has no implementation steps. As the name “ZTD” suggests, it's a zero touch deployment. As long as bootstrapping happened successfully by having the IoT Gateway part of the right bootstrapping group, this deployment should happen successfully with no manual steps.

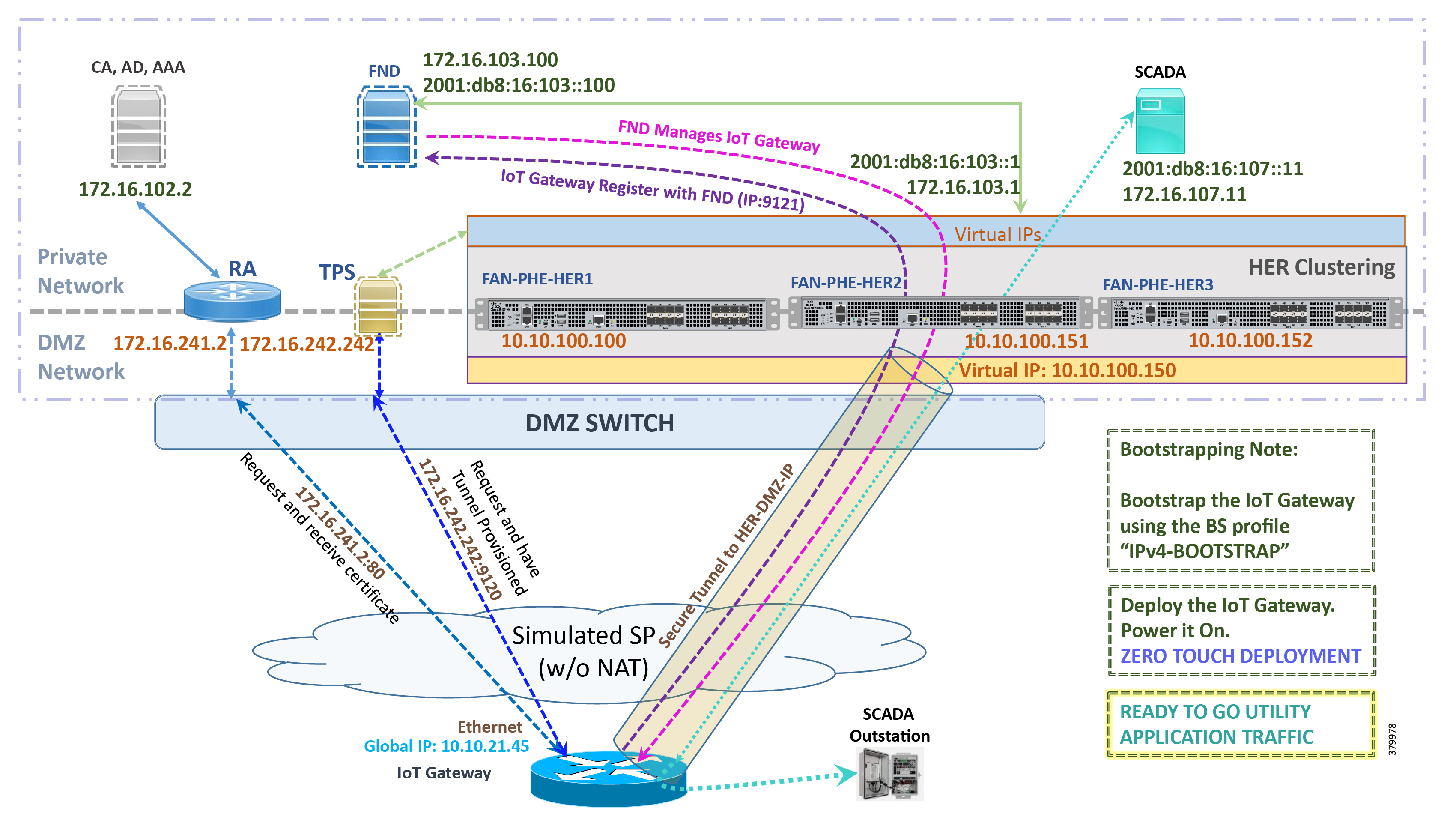

Figure 33 captures the deployment steps for IoT Gateway without NAT over the IPv4 network:

Figure 33 Deployment over IPv4 Ethernet Network in Engineering Lab Topology

Note: This scenario has been validated with the headend located in the Engineering Lab Topology.

The following is the summary sequence of steps that happens during the deployment:

1.![]() The IoT Gateway is powered on. When up, it obtains the IP address over the Ethernet interface.

The IoT Gateway is powered on. When up, it obtains the IP address over the Ethernet interface.

2.![]() The EEM Script for ZTD kicks in and waits for the time to be synchronized. Then, SCEP enrollment happens with RA IP (172.16.241.2) on port 80.

The EEM Script for ZTD kicks in and waits for the time to be synchronized. Then, SCEP enrollment happens with RA IP (172.16.241.2) on port 80.

3.![]() Once the certificate is received for the IoT Gateway (from the RA/CA), the ZTD script disables itself, and activates the CGNA profile for tunnel provisioning (cgna profile cg-nms- tunnel).

Once the certificate is received for the IoT Gateway (from the RA/CA), the ZTD script disables itself, and activates the CGNA profile for tunnel provisioning (cgna profile cg-nms- tunnel).

Note: “cgna profile cg-nms-tunnel ” must be used when there is no NAT between IoT Gateway and TPS. This CGNA profile has already been configured as part of IoT Gateway bootstrapping. TPS/FND provisions secure FlexVPN tunnel with the HER Cluster located in the DSO Control Center1.

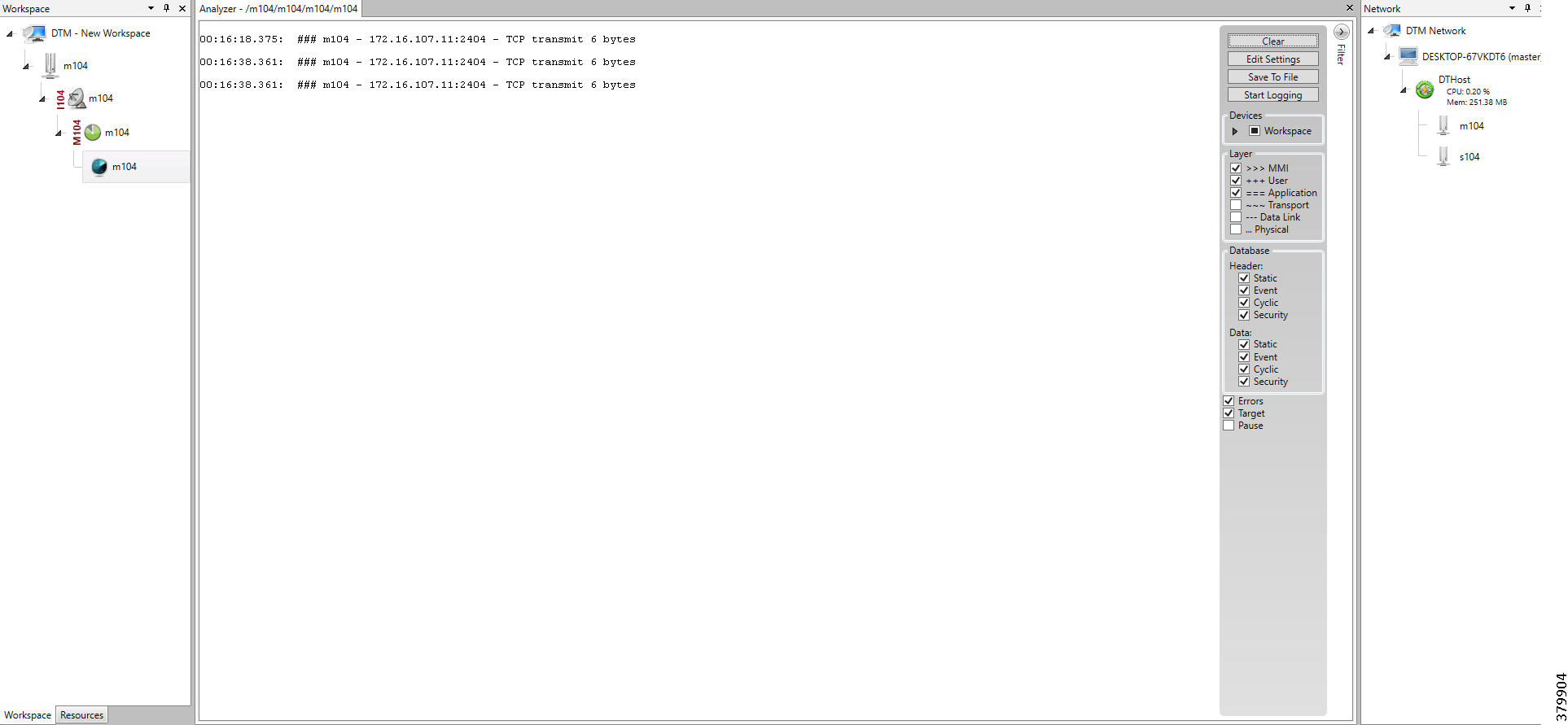

4.![]() As an overlay routing, FND (172.16.103.100 and 2001:db8:16:103::100) and SCADA (172.16.107.11 and 2001:db8:16:107::11) routes are advertised (by HER) to the IoT Gateway through the secure FlexVPN tunnel.

As an overlay routing, FND (172.16.103.100 and 2001:db8:16:103::100) and SCADA (172.16.107.11 and 2001:db8:16:107::11) routes are advertised (by HER) to the IoT Gateway through the secure FlexVPN tunnel.

5.![]() IoT Gateway sends out a registration request to FND IPv4 address 172.16.103.100 (or) IPv6 address 2001:db8:16:103::100 on port 9121. Once registered successfully, the IOT Gateway is remotely manageable from the FND.

IoT Gateway sends out a registration request to FND IPv4 address 172.16.103.100 (or) IPv6 address 2001:db8:16:103::100 on port 9121. Once registered successfully, the IOT Gateway is remotely manageable from the FND.

6.![]() As part of the device registration with the FND, FND also pushes SCADA Traffic enablement configurations to the IoT Gateway, which enables the communication between SCADA Master in the Control Center and the SCADA Outstation located in the Secondary Substation/Distribution Network.

As part of the device registration with the FND, FND also pushes SCADA Traffic enablement configurations to the IoT Gateway, which enables the communication between SCADA Master in the Control Center and the SCADA Outstation located in the Secondary Substation/Distribution Network.

Deployment over Native IPv6 Ethernet Network

Note: This section has no implementation steps. As the name “ZTD” suggests, it's a zero touch deployment. As long as bootstrapping happened successfully by having the IoT Gateway part of the right bootstrapping group, this deployment should happen successfully with no manual steps being synchronized.

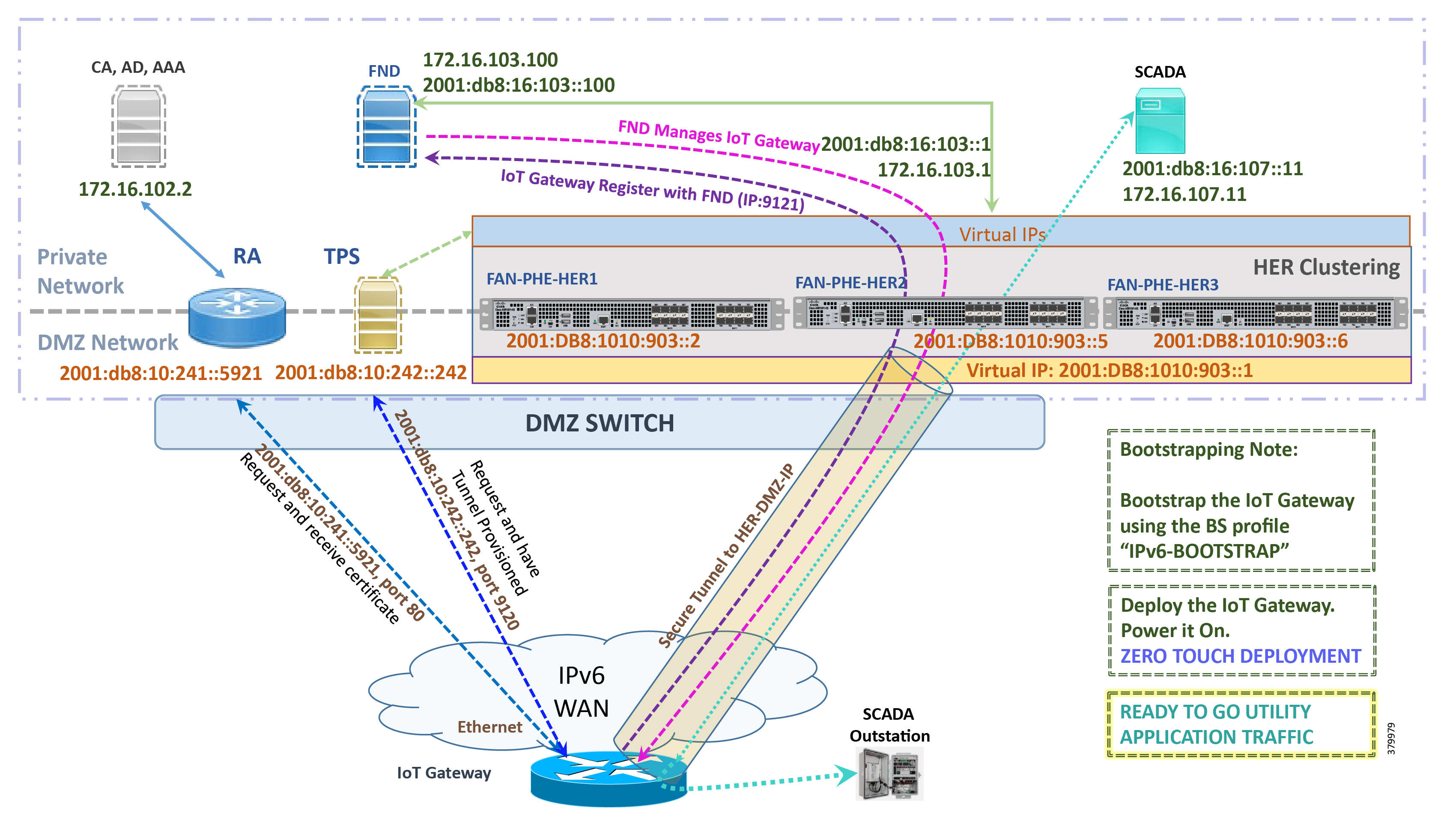

Figure 34 captures the deployment steps for the IoT Gateway over the Native IPv6 network:

Figure 34 Deployment over Native IPv6 Ethernet Network in Engineering Lab Topology

Note: This scenario has been validated with the headend located in the Engineering Lab Topology over a native IPv6 network. It could be dual stack as well.

The following is the summary sequence of steps that happens during the deployment:

1.![]() The IoT Gateway is powered on. When up, it obtains the IPv6 address over the Ethernet interface.

The IoT Gateway is powered on. When up, it obtains the IPv6 address over the Ethernet interface.

2.![]() The EEM script for ZTD kicks in and waits for the time to be synchronized. Then, SCEP enrollment happens with RA IPv6 address (2001:db8:10:241::5921) on port 80.

The EEM script for ZTD kicks in and waits for the time to be synchronized. Then, SCEP enrollment happens with RA IPv6 address (2001:db8:10:241::5921) on port 80.

3.![]() IPv4 communication could be retained between RA and CA in the Control Center private network.

IPv4 communication could be retained between RA and CA in the Control Center private network.

4.![]() Once the certificate is received for the IoT Gateway (from the RA/CA), the ZTD script disables itself, and activates the CGNA profile for tunnel provisioning.

Once the certificate is received for the IoT Gateway (from the RA/CA), the ZTD script disables itself, and activates the CGNA profile for tunnel provisioning.

Note: “cgna initiator-profile cg-nms-tunnel” must be used when the IoT Gateway is behind NAT, whereas “ cgna profile cg-nms-tunnel” must be used when there is no NAT between IoT Gateway and TPS. This CGNA profile has already been configured as part of the IoT Gateway bootstrapping.

5.![]() TPS/FND provisions secure the FlexVPN tunnel with the HER Cluster located in the DSO Control Center1, over the Native IPv6 network.

TPS/FND provisions secure the FlexVPN tunnel with the HER Cluster located in the DSO Control Center1, over the Native IPv6 network.

6.![]() As an overlay routing, FND (172.16.103.100 and 2001:db8:16:103::100) and SCADA (172.16.107.11 and 2001:db8:16:107::11) routes are advertised (by HER) to the IoT Gateway through the secure FlexVPN tunnel.

As an overlay routing, FND (172.16.103.100 and 2001:db8:16:103::100) and SCADA (172.16.107.11 and 2001:db8:16:107::11) routes are advertised (by HER) to the IoT Gateway through the secure FlexVPN tunnel.

7.![]() IoT Gateway sends out a registration request to FND IPv4 address 172.16.103.100 (or) IPv6 address 2001:db8:16:103::100 on port 9121. Once registered successfully, IOT Gateway is remotely manageable from the FND.

IoT Gateway sends out a registration request to FND IPv4 address 172.16.103.100 (or) IPv6 address 2001:db8:16:103::100 on port 9121. Once registered successfully, IOT Gateway is remotely manageable from the FND.

8.![]() As part of the device registration with the FND, FND also pushes SCADA Traffic enablement configurations to the IoT Gateway, which enables the communication between SCADA Master in the Control Center and the SCADA Outstation located in the secondary substation/Distribution Network.

As part of the device registration with the FND, FND also pushes SCADA Traffic enablement configurations to the IoT Gateway, which enables the communication between SCADA Master in the Control Center and the SCADA Outstation located in the secondary substation/Distribution Network.

Tunnel Provisioning Template Profiles

Tunnel Provisioning Template profiles, which are needed for Tunnel establishment, are captured in Appendix B: FND Zero Touch Deployment Profiles.

Device Configuration Template Profiles

Device Configuration Template profiles, which are needed for ICT SCADA Traffic enablement, are captured in Appendix B: FND Zero Touch Deployment Profiles.

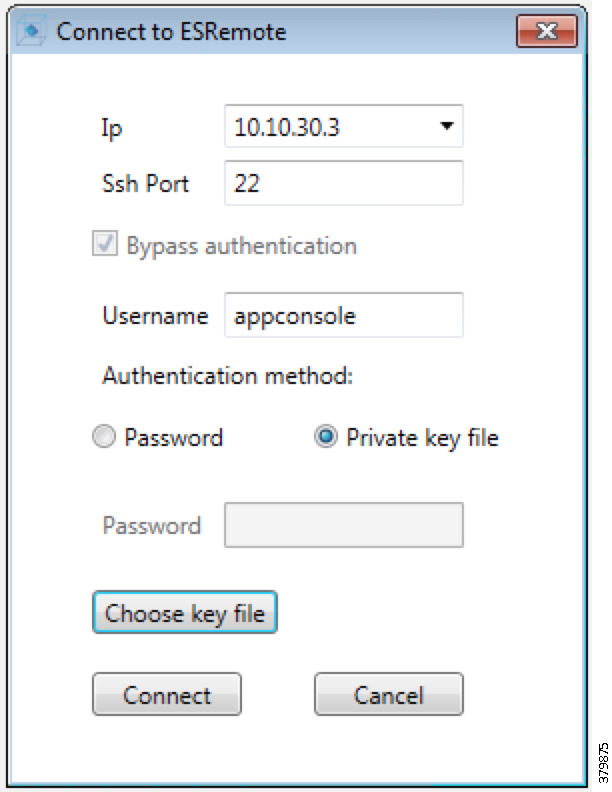

Bootstrapping and ZTD of the Cisco IoT Gateway at the Deployment Location

This section describes the bootstrapping and Deployment of the Cisco IoT gateway at the deployed location. Unlike the previous section, one TPS and FND are sufficient to complete both bootstrapping and ZTD. Although the previous two sections and this section overlap, minor changes in the implementation of TPS and FND need to be done for successful deployment.

This section, which covers the minor changes that have to be implemented in the headend setup, describes the following phases:

Prerequisites

Prerequisites include the following:

■![]() TPS and FND server must be up and running.

TPS and FND server must be up and running.

■![]() This section focuses on portions required for TPS and FND to carry out both bootstrapping and ZTD.

This section focuses on portions required for TPS and FND to carry out both bootstrapping and ZTD.

■![]() Routing reachability over IPv4 and/or IPv6 networks from IoT Gateways to TPS.

Routing reachability over IPv4 and/or IPv6 networks from IoT Gateways to TPS.

Certificate Creation and Installation

This section captures the parameters that need to be considered while creating the certificate for the TPS and FND.

Note: For detailed instructions about certificate creation, please refer to the section “Creation of Certificate Templates and Certificates” of the Cisco FAN-Headend Deep Dive Implementation and FAN Use Cases Guide at the following URL:

■![]() https://docs.cisco.com/share/proxy/alfresco/url?docnum=EDCS-15726915

https://docs.cisco.com/share/proxy/alfresco/url?docnum=EDCS-15726915

Certificate Creation for TPS

The certificate for the TPS must be created with both the Subject Name and the Subject Alternative Name fields populated.

Figure 35 TPS Certificate Parameters

The Subject Name is the Common Name that must be set to the FQDN of the TPS.

The Subject Alternative Name must be set to the FQDN - tps.ipg.cisco.com of the TPS, along with the IP address (A.B.C.D - Public reachable DMZ IP). The Subject Alternative Name is required for PnP to work. The IP address must be reachable from the IoT Gateway. TPS is located in DMZ. The IP address is not optional in this implementation. FQDN is optional, but the IP address is not.

The enrolled certificate is exported as PnP-ZTD-TPS.pfx and is protected with a password.

Certificate Creation for FND

The FND certificate must be created with both the Subject Name and Subject Alternative Name fields populated.

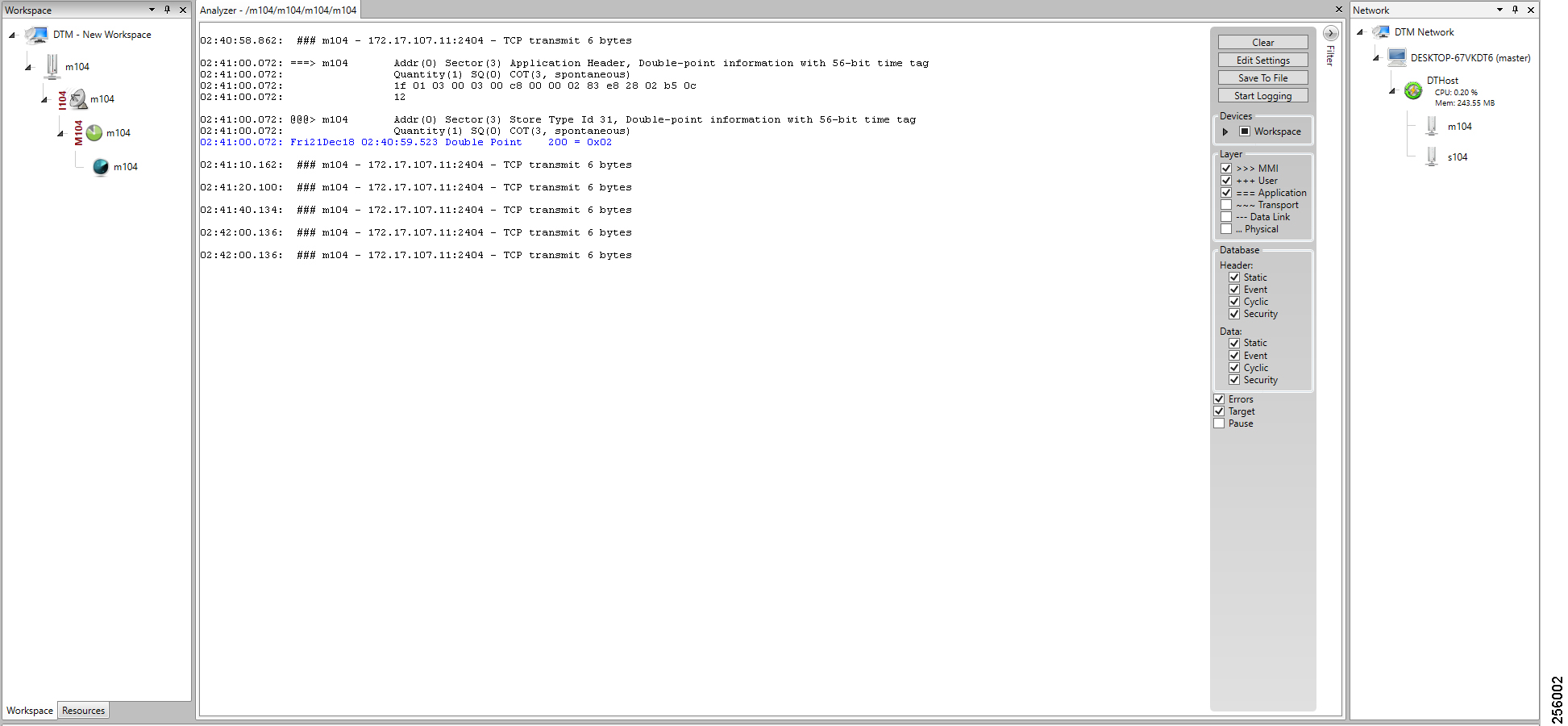

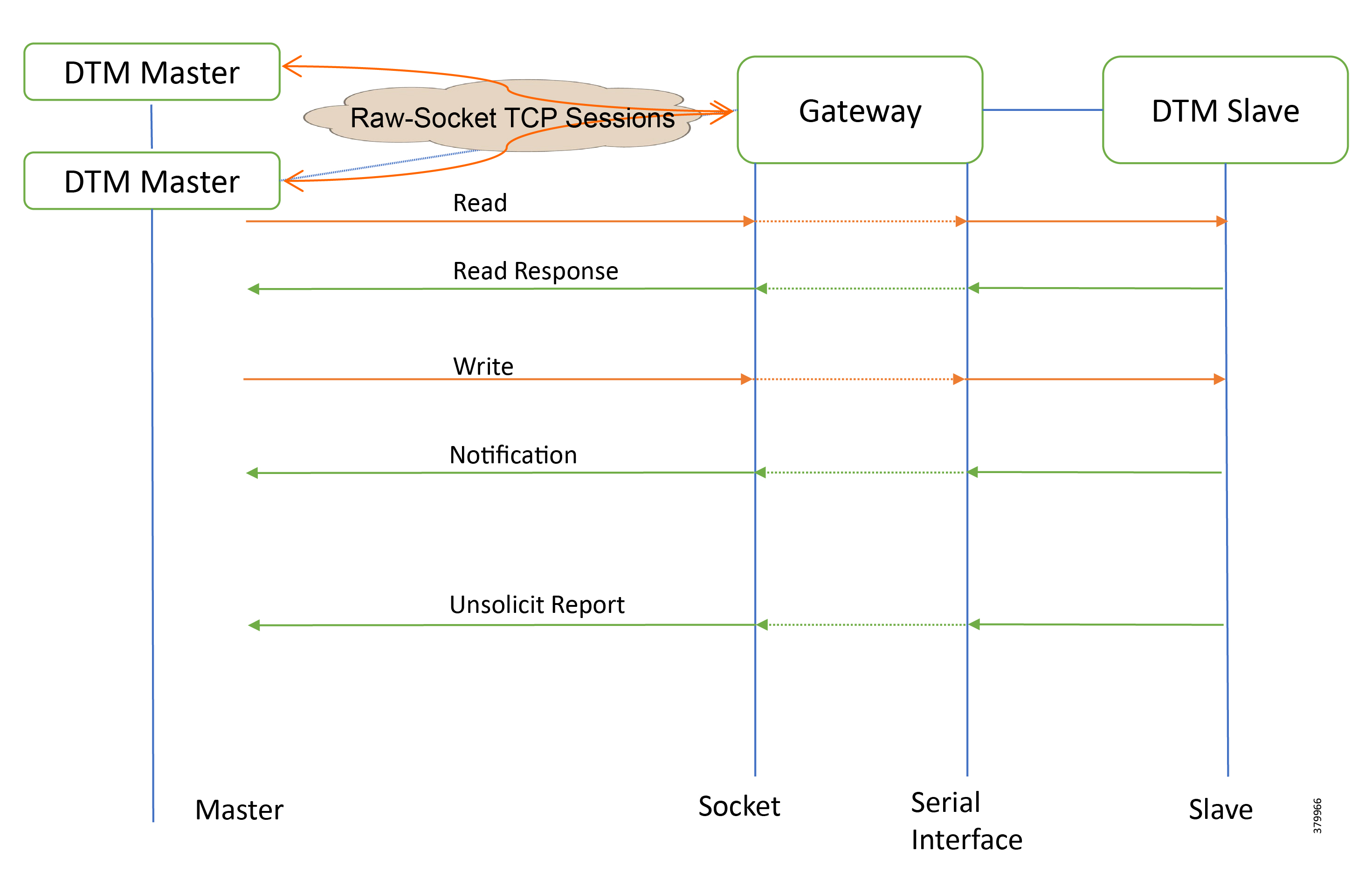

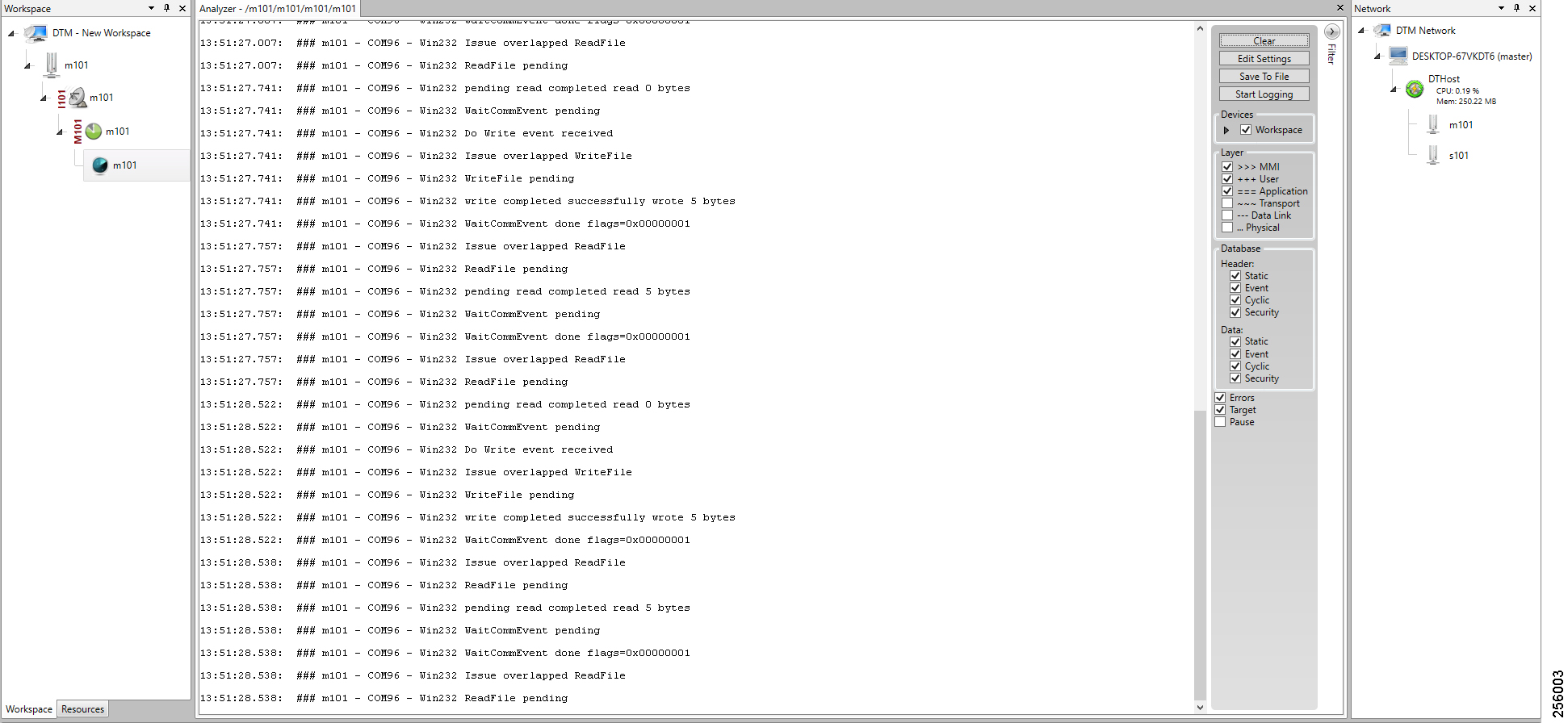

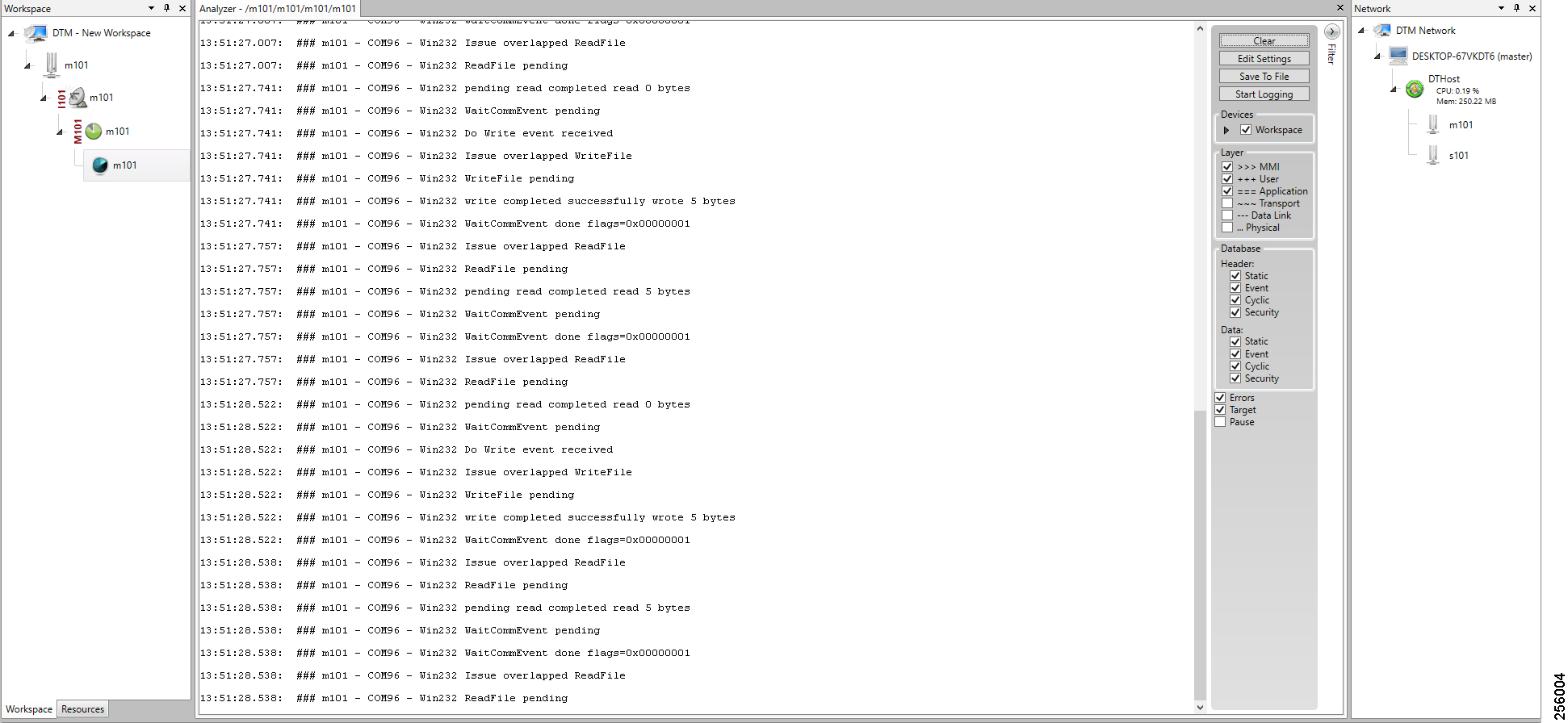

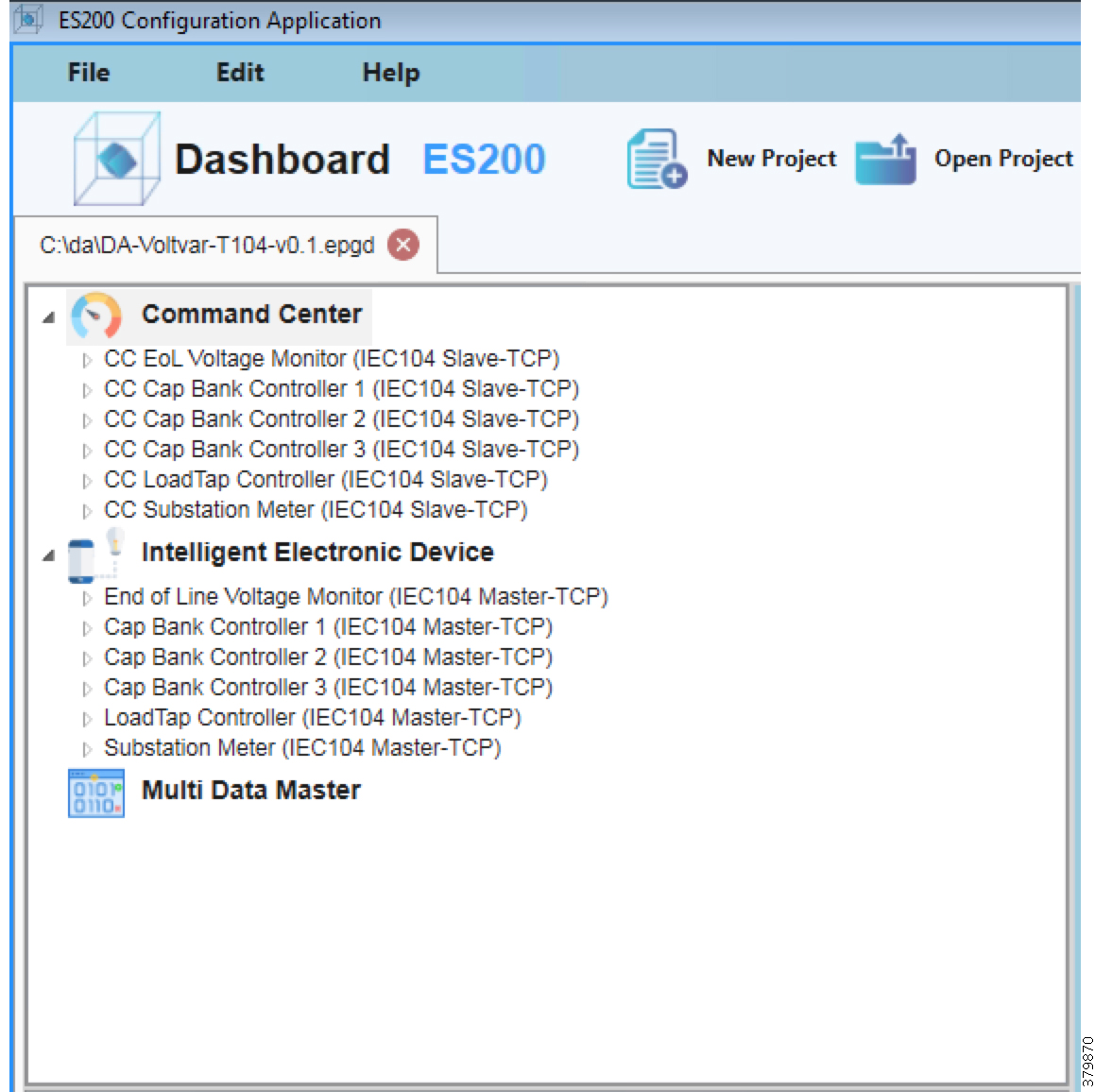

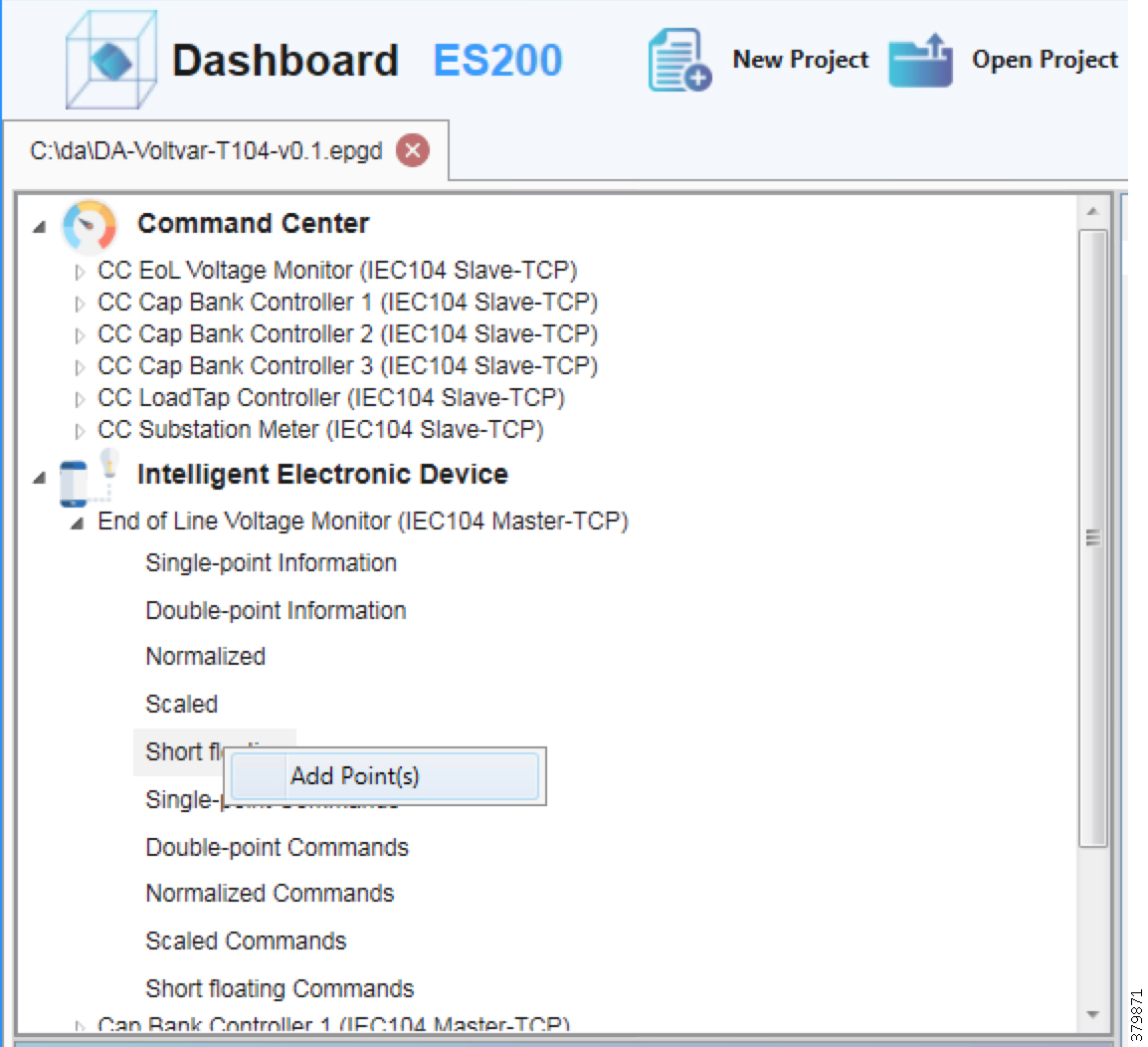

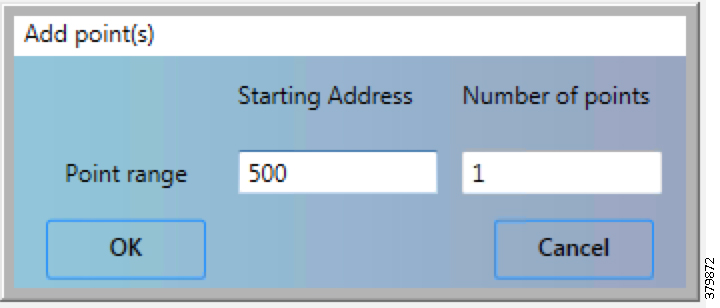

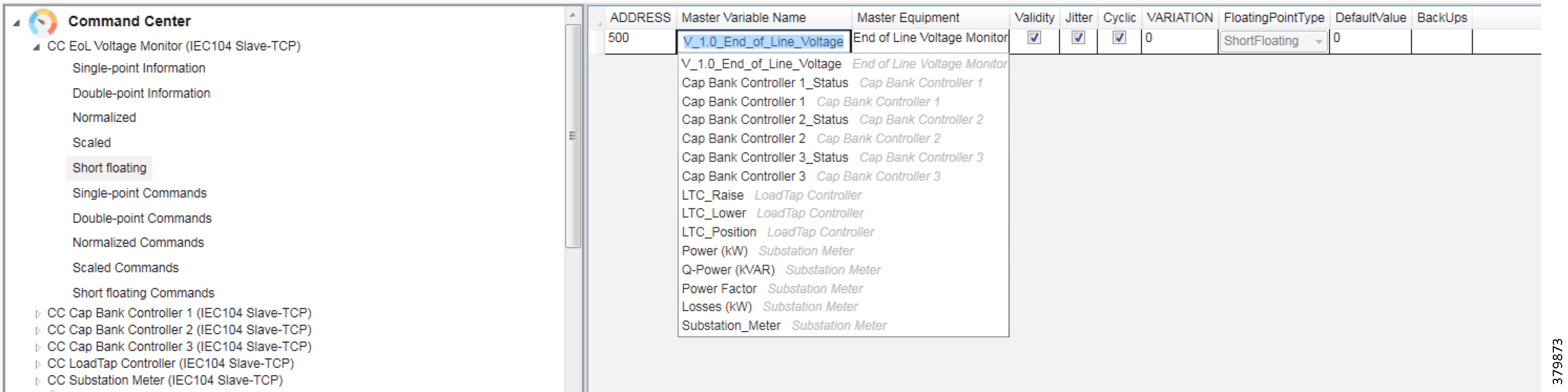

Figure 36 FND Certificate Parameters