Installing Power Components

Power Connection Guidelines

Ensure all power connection wiring conforms to the rules and regulations in the National Electrical Code (NEC) as well as local codes.

The chassis has two power trays. Each power tray includes four power modules. The power tray provides electrical connections to the chassis backplane. Each power module can be individually plugged in or out from the tray.

Caution |

Proper grounding is necessary to avoid damage from lightning and power surges. See the NEBS Supplemental Unit Bonding and Grounding Guidelines for grounding requirements. |

DC-Powered Chassis

Use a 6 AWG wire rated 75°C minimum, for DC power modules connection. The system accepts a nominal input voltage of -48 VDC or -60VDC, with an operational tolerance range of -40.5 to -72 VDC. One dedicated, commensurately rated DC power source is required for each power module connection. Each power feed shall be provided with a double pole breaker, rated not more than 60A, with medium delay.

Note |

Follow the power and sizing requirements for your site. |

Note |

The Short Circuit protection Breaker shall not be rated more than 60A. |

Power redundancy requirements vary based on the system configuration (number of cards present in the chassis and traffic load). DC-powered systems are N+1 protected.

Power connections to the power tray for each DC power module requires four cables: two source cables and two return cables.

For DC power cables, we recommend 6 AWG high-strand-count copper wire cables, rated 75°C minimum. The size of the cables depends on your chassis location from the source power. Follow your local practices for determining cable size. DC power cables are not available from Cisco, but they are available from any commercial cable vendor.

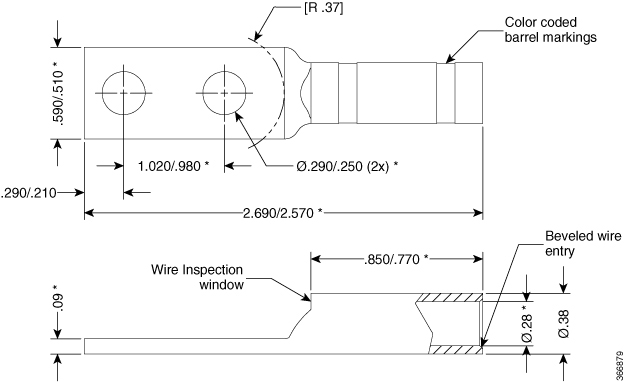

You must terminate DC power cables using cable lugs at the power tray end. The lugs required for the input power are provided with the power modules.

Warning |

Hazardous voltage or energy may be present on power terminals. Always replace cover when terminals are not in service. Be sure uninsulated conductors are not accessible when cover is in place. Statement 1086 |

Warning |

Only trained and qualified personnel should be allowed to install, replace, or service this equipment. Statement 1030 |

Note |

Before connecting DC power cables to the power system, make sure that the input power cords are not energized. |

Note |

Ensure that there is a readily accessible disconnect device incorporated in the building’s installation wiring. |

Note |

Circuit breaker and fuse lockout procedures should follow the rules and regulations in the National Electrical Code (NEC) and any local codes. |

Warning |

To avoid shock hazard, be sure to apply shrink wrap tubing around the wire entry area of the lug. |

The color coding of source DC power cable leads depends on the color coding of the site DC power source. Because there is no color code standard for source DC wiring, be sure that power source cables are connected to the power modules using the proper positive (+) and negative (–) polarity:

- In some cases, the source DC cable leads might have a positive (+) or a negative (–) label. This is a relatively safe indication of the polarity, but you must verify the polarity by measuring the voltage between the DC cable leads . Be sure that the positive (+) and negative (–) cable leads match the positive (+) and negative (–) labels on the power module when making the measurement.

- A green (or green and yellow) cable typically indicates that it is a ground cable.

Caution |

DC power modules contain reverse voltage protection circuitry to prevent damage to the power module if it detects a reverse polarity condition. No damage should occur from reverse polarity, but you should correct a reverse polarity condition immediately. |

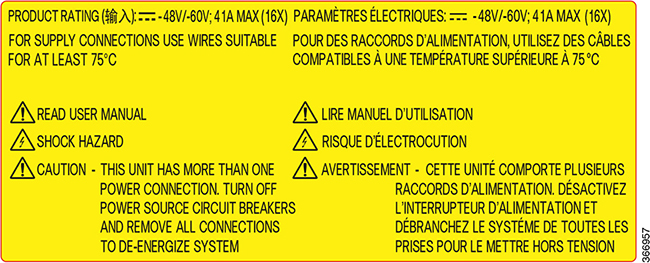

The rating label is shown in the figure below.

General Power and Grounding Requirements

This section describes the power and grounding requirements you must consider when planning the site facilities for the routing system. In addition, see the DC Power Requirements for additional information about the power requirements for your chassis type.

Note |

A qualified electrician should review the information in these sections to ensure that the installation site meets these requirements. For larger system configurations, consult a facilities electrical expert to understand the load that the routing system may put on the facility power plant. |

General power and grounding requirements are:

- Installation of the routing

system must follow national and local electrical codes:

- In the United States: United States National Fire Protection Association (NFPA) 70 and United States National Electrical Code (NEC).

- In Canada: Canadian Electrical Code, part I, CSA C22.1.

- In other countries: International Electrotechnical Commission (IEC) 60364, parts 1 through 7.

- Two separate and independent DC power sources are needed to provide 2N redundancy for system power. Each power source requires its own circuit breaker.

- Each power source must provide clean power to the site. If necessary, install a power conditioner.

- The site must provide short-circuit (over-current) protection for devices.

- Proper grounding is required

at the site to ensure that equipment is not damaged by lightning and power

surges. In addition:

- Chassis grounding is required for DC-powered systems.

- Site power planning must include the power requirements for any external terminals and test equipment you will use with your system.

Note |

Be sure to review the safety warnings in the Regulatory Compliance and Safety Information for Cisco NCS 4000 Series before attempting to install the routing system. |

DC Power Requirements

Observe the following guidelines for DC-powered shelves. In addition, be sure to review the requirements described in theGeneral Power and Grounding Requirements .

- A DC-powered chassis requires up to a maximum of 12,250 watts of DC input power when the chassis is fully loaded.

- All power connection wiring must conform to the rules and regulations in the National Electrical Code (NEC) and any local codes. In addition, make sure that the wiring conforms to any internal requirements at the installation site.

- Each DC power source must comply with the safety extra-low voltage (SELV) requirements in UL 60950-1, CSA-C22.2 No. 60950-1, EN60950-1, AS/NZS 60950, and IEC60950-1.

- A DC-powered system should be installed in a restricted access area in accordance with the National Electric Code, ANSI/NFPA 70.

- All components in the area where DC input power is accessible must be properly insulated.

If it is not possible to rely on the identification of the earthed conductor in the DC mains supply, whereby the equipment is not provided with a two-pole disconnect device, then a two-pole disconnect device is to be provided external to the equipment.

NEBS Supplemental Unit Bonding and Grounding Guidelines

You must connect the central office ground system or interior equipment grounding system permanently to one of the two supplemental bonding and grounding connections on the back or side of the chassis to meet Network Equipment Building System (NEBS) requirements as well as safety compliance requirements. These grounding points are referred to as the NEBS bonding and grounding points.

Note |

These bonding and grounding connections satisfy the Telcordia NEBS requirements for supplemental bonding and grounding connections. If you are not installing the chassis in a NEBS environment, you can choose to bypass these guidelines and rely on the safety earth ground connections to the DC power modules. |

There are five grounding points on the Cisco NCS 4000 FCC as seen in the figure below.

|

1 |

Screws and washers |

|

2 |

Grounding lug with cable |

|

3 |

Grounding point |

To ensure a satisfactory supplemental ground connection to the chassis, use the following parts:

- One grounding lug, which has #10 stud holes with 5/8 spacing between them, and a wire receptacle able to accept a 4-AWG or larger, multistrand copper wire. This lug is similar to those used for the DC input power supply leads.

- Two M6 round-head screws and two locking washers.

- One grounding wire. Although we recommend at least 4-AWG multistrand copper wire, the wire diameter and length depend on your chassis location and site environment.

Installing the Chassis Ground Cable

This section describes how to install a ground cable to either NEBS bonding and grounding point on the front or side of the Cisco NCS 4000 FCC.

Required Tools and Equipment

- Ground lug and screws (provided in chassis accessory kit)

- Ground cable

- Crimping tool and lug specific die

- Number-2 Phillips screwdriver

To ensure a satisfactory ground connection, we recommend 4-AWG multistrand copper ground cable. The cable should be sized according to local and national installation requirements.

Note |

The chassis ground cable must be connected first to the chassis before any other connections are made. During removal of the chassis, the ground cable must be disconnected last. |

Note |

The DC return of this system should remain isolated from the system frame and chassis (DC-I: Isolated DC Return). The DC return must be connected to the ground at source. |

To attach the ground cable to the chassis, follow these steps:

Procedure

|

Step 1 |

Use the crimping tool mandated by the lug manufacturer to crimp the lug to the ground cable.

|

||||||

|

Step 2 |

Use the Phillips screwdriver to tighten the screws to a torque of 22-25 in-lb. |

||||||

|

Step 3 |

Connect the other end of the ground cable to a grounding point at your site, according to site requirements. |

Installing DC Power Tray

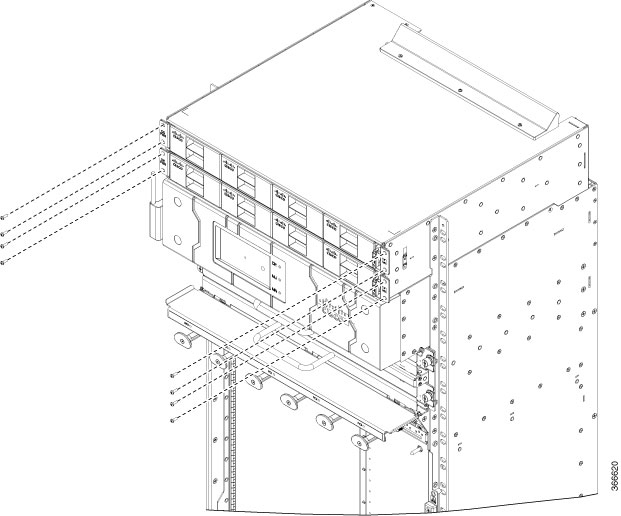

This section describes how to install a DC power tray in the chassis.

Required Tools and Equipment

- 6-inch, number-1 Phillips screwdriver

- Cisco NCS 4000 FCC power trays (Cisco PIDNCS4K-DC-PEM)

To install a DC power tray, follow these steps:

Procedure

|

Step 1 |

Slide the power tray into the bay until it engages its mating connector on the chassis. |

|

Step 2 |

Fully seat the power tray into its mating connector and seat the power tray mounting ears against the chassis mounting ears. |

|

Step 3 |

Install and tighten the screws (for each power tray) through the power tray mounting ears on each side into the screw holes in the chassis mounting ears to secure the tray to the chassis using a torque of 6 in-lb.  |

Installing Power Modules

This section describes how to install power modules into the chassis.

Caution |

Never force a power module into the power tray if you feel any resistance! Forcing a module into the incorrect tray can cause damage to the module and the tray. |

Each power module has three status LEDs located on the front left side of its faceplate.

|

LED Name |

Color |

Meaning |

|---|---|---|

|

Input OK |

Green |

|

|

Output OK |

Green |

|

|

Fault |

Red |

|

Installing DC Power Modules

This section describes how to install DC power modules.

Required Tools and Equipment

- Cisco NCS 4000 FCC power modules (NCS4K-DC-PSU-V1)

Caution |

To prevent damage to the power tray backplane connector, do not use excessive force when inserting the power module into the power tray. |

To install the DC power modules into the chassis, follow these steps:

Procedure

|

Step 1 |

Remove the filler caps from the slots where you want to install the power modules. |

|

Step 2 |

Using two hands to support the power module, slide it into the power tray.  |

|

Step 3 |

Secure the power module into the power tray using the snap hook. |

|

Step 4 |

Repeat these steps for the other DC power modules. |

Connecting Power to a DC-Powered Chassis

This section explains how to connect the DC source power cables to a DC-powered chassis.

The color coding of source DC power cable leads depends on the color coding of the site DC power source. Because there is no color code standard for source DC wiring, you must be sure that power source cables are connected to the power module with the proper positive (+) and negative (–) polarity:

- In some cases, the source DC cable leads might have a positive (+) or a negative (–) label. This is a relatively safe indication of the polarity, but you must verify the polarity by measuring the voltage between the DC cable leads . Be sure that the positive (+) and negative (–) cable leads match the positive (+) and negative (–) labels on the power module when making the measurement.

- Green (or green and yellow) cable typically indicates that it is a ground cable.

Caution |

DC power modules contain circuitry to trip the breaker on the power module if the power module detects a reverse polarity condition. No damage should occur from reverse polarity, but you should correct a reverse-polarity condition immediately. |

Warning |

To ensure that power remains off while you are performing this procedure, lock-out/tag-out the DC circuit breaker switch in the OFF (0) position until you are ready to turn it on. |

To connect the DC source power cables to a DC power tray, follow these steps :

Procedure

|

Step 1 |

Verify that the power switch is set to the OFF (0) position. The power switch is on the right of the power tray. |

||||

|

Step 2 |

Remove the clear plastic safety covers that fit over the DC power connection terminal studs. |

||||

|

Step 3 |

Verify the following resistance values on both power shelves:

|

||||

|

Step 4 |

Connect the DC power cables in the following order:

|

||||

|

Step 5 |

Repeat Step-4 for the other power modules installed in the tray.

|

||||

|

Step 6 |

Replace the clear plastic safety covers over the connection terminal studs. |

||||

|

Step 7 |

Proceed to the Powering On the Chassis. |

Disconnecting DC Power

The following sections explain how to disconnect DC power to the FCC.

Disconnecting DC Power From a Single Power Module

Caution |

It is not necessary to disconnect all power from the chassis to replace components, including power modules. |

To disconnect an individual DC power source from a power tray, follow these steps:

Procedure

|

Step 1 |

Power off the circuit breaker assigned to the DC power source you are disconnecting.

|

||

|

Step 2 |

Remove the clear plastic safety covers that fit over the DC power connection terminal studs.

|

||

|

Step 3 |

Disconnect the DC power cables from their terminals in the following order and note the color of each cable:

|

||

|

Step 4 |

Repeat Step-1 through Step-3 for the other power module distribution that needs to be removed. |

Disconnecting DC Power From All Power Modules In a Power Tray

To disconnect power from all power modules in a single power tray, follow these steps:

Note |

The procedure is the same for each DC power tray, if more than one is installed. |

Caution |

If only one power tray is installed, performing the following procedure turns off all power to the chassis. |

Procedure

|

Step 1 |

Set the power tray switch to the OFF (0) position. |

||

|

Step 2 |

Power off (0) the circuit breaker assigned to the DC power source you are disconnecting.

|

||

|

Step 3 |

Remove the clear plastic safety covers that fit over the DC power connection terminal studs.

|

||

|

Step 4 |

Disconnect the DC power cables from their terminals in the following order and note the color of each cable:

|

||

|

Step 5 |

Repeat Step 1 through Step 4 for the other power tray, if installed.

|

Reconnecting DC Power

To reconnect DC power to a DC power tray, see Connecting Power to a DC-Powered Chassis.

Powering On the Chassis

To turn on power to a DC-powered chassis, follow these steps:

Procedure

|

Step 1 |

Power on the circuit breaker to your power sources one at a time. |

||

|

Step 2 |

Verify that the correct Power Input LED on each power module in the tray is lit. Continue with steps 1 and 2 until all inputs have been verified.

|

||

|

Step 3 |

Set the power tray switch to the ON (1) position. This powers on slots PWR MOD 0 through PWR MOD 3. |

||

|

Step 4 |

Verify that the Power Output LED on each power module in the tray is lit. |

||

|

Step 5 |

Repeat Step 3 and Step 4 for the other power tray. |

Feedback

Feedback